Device and method for testing mechanical properties of water filter pipes

A test method and technology for water filter pipes, which are applied in the direction of using stable torsion to test the strength of materials, and using stable tension/pressure to test the strength of materials, etc. It is convenient for integrated control, convenient for pressure maintenance, and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

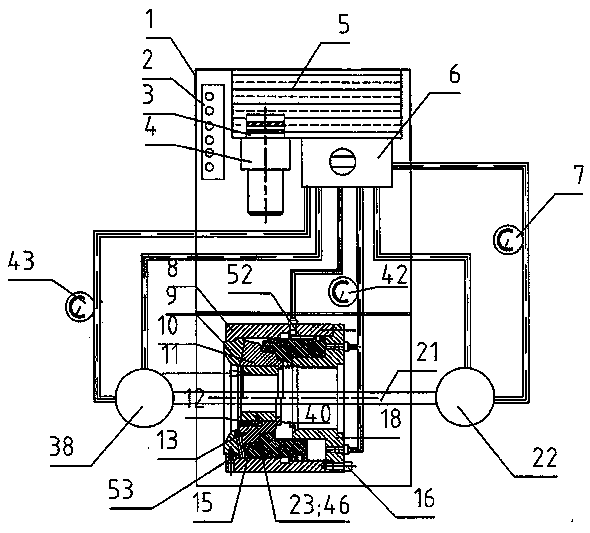

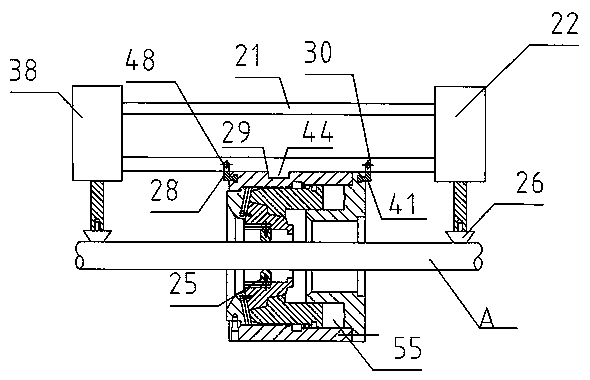

[0038] see Figure 1 to Figure 7As shown, the filter pipe mechanical performance testing device of the present invention is composed of a frame 1, a control panel 2, a hydraulic pump 3, a motor 4, an oil tank 5, an integrated valve 6, a second pressure gauge 7, a cylinder body 8, a front cover 9, Extrusion die base 10, extrusion die 11, die screw 12, screw 13, countersunk screw 14, extrusion block 15, screw 16, first oil inlet and outlet joint 17, rear end cover 18, second oil inlet and outlet joint 19, The third oil inlet and outlet joint 20, the connecting rod 21, the first hydraulic cylinder 22, the first fast-forward slope 23, the first working slope 24, the fixed mold 25, the triangular pressure head 26, the cable tie 27, the first fixture 28, the groove 29. The second positioning pin 30, the flat bottom pressure head 31, the first electromagnetic reversing valve 32, the second electromagnetic reversing valve 33, the third electromagnetic reversing valve 34; the first hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com