Head of burking machine

A crimping machine and machine head technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high resistance, complex structure, and slow extrusion block, and achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

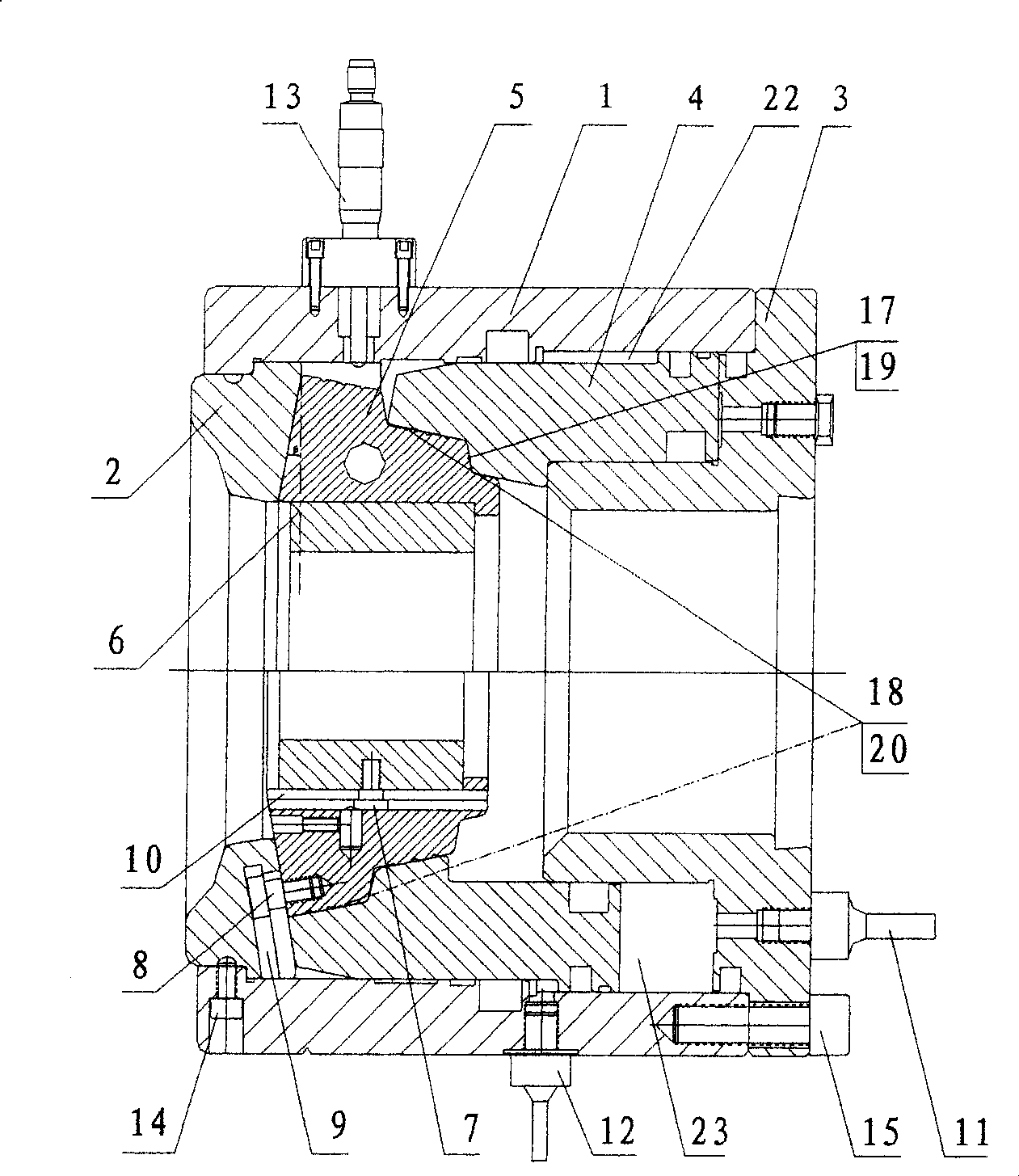

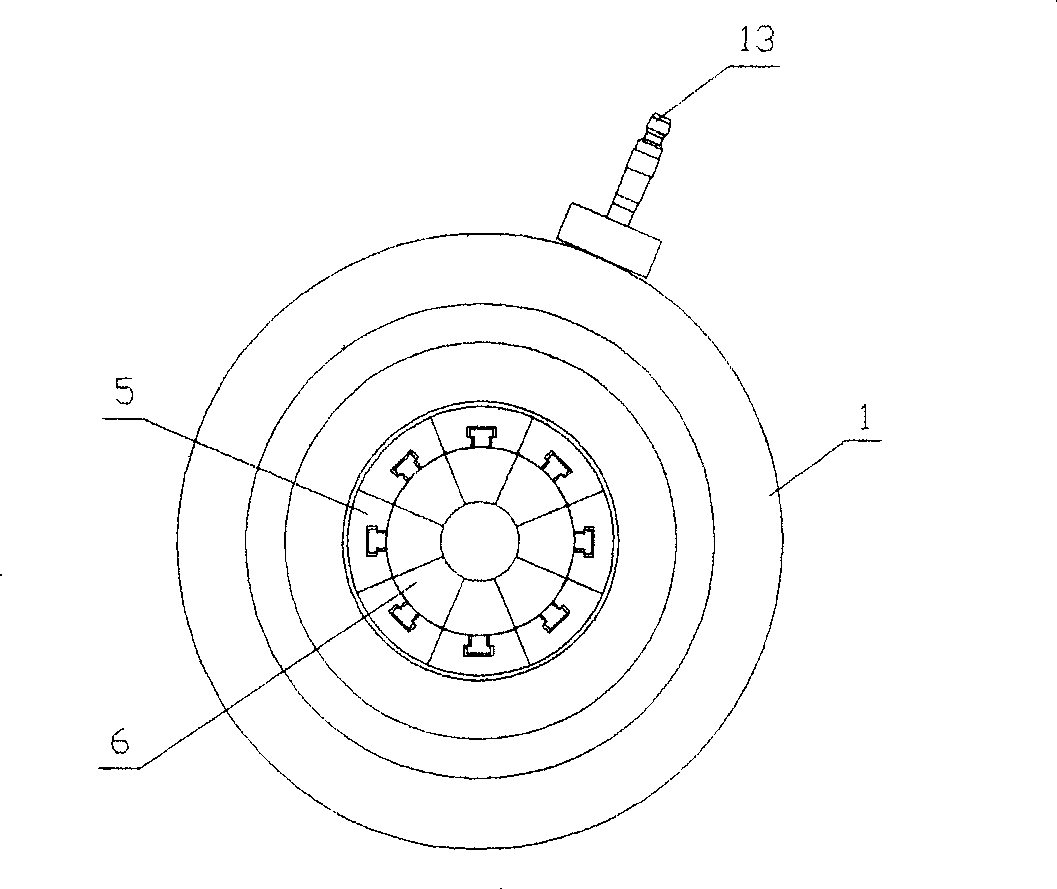

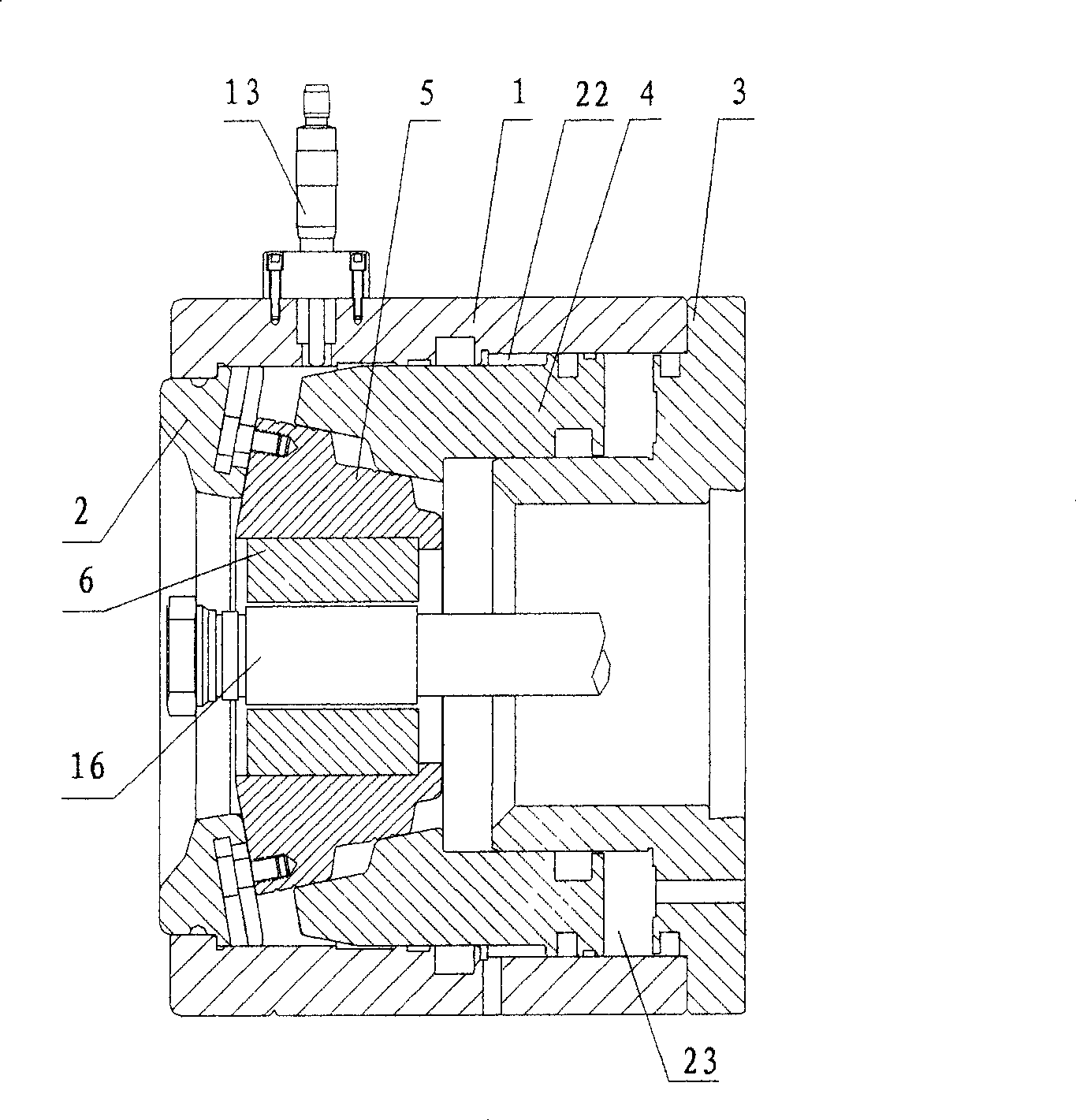

[0017] Embodiments of the present invention: as attached figure 1 As shown, it is composed of an oil cylinder 1, a front end cover 2, a rear end cover 3, an extrusion block 4, a mold extrusion seat 5 and a mold 6. They are respectively connected to the front end and the rear end of the oil cylinder 1, a chute 9 is provided on the sloped surface of the front end cover 2, and a chute 10 is provided on the mold extrusion seat 5, and the mold 6 is connected to the mold through the mold screw 7. On the extrusion seat 5, the mold extrusion seat 5 is connected to the front end cover 2 through a screw 8, wherein one end of the mold screw 7 is inserted in the chute 10, and one end of the screw 8 is inserted in the chute 9, and the screw 8 is T-shaped screw, mold screw 7 and T-shaped screw 8 can slide along the chute 10 and chute 9 respectively. Since the end face of the front end cover 2 is a pot-shaped slope with a certain slope, the mold extrusion seat 5 can be combined with the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com