Rail loop power supply vehicle

A track loop and track technology, applied in the field of track loop powered vehicles, can solve the problem of not emitting exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

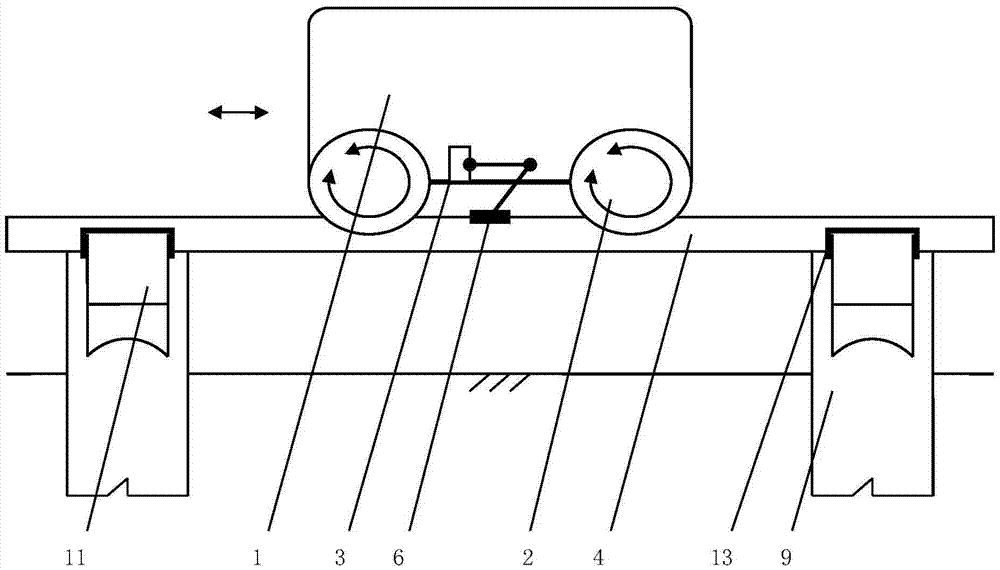

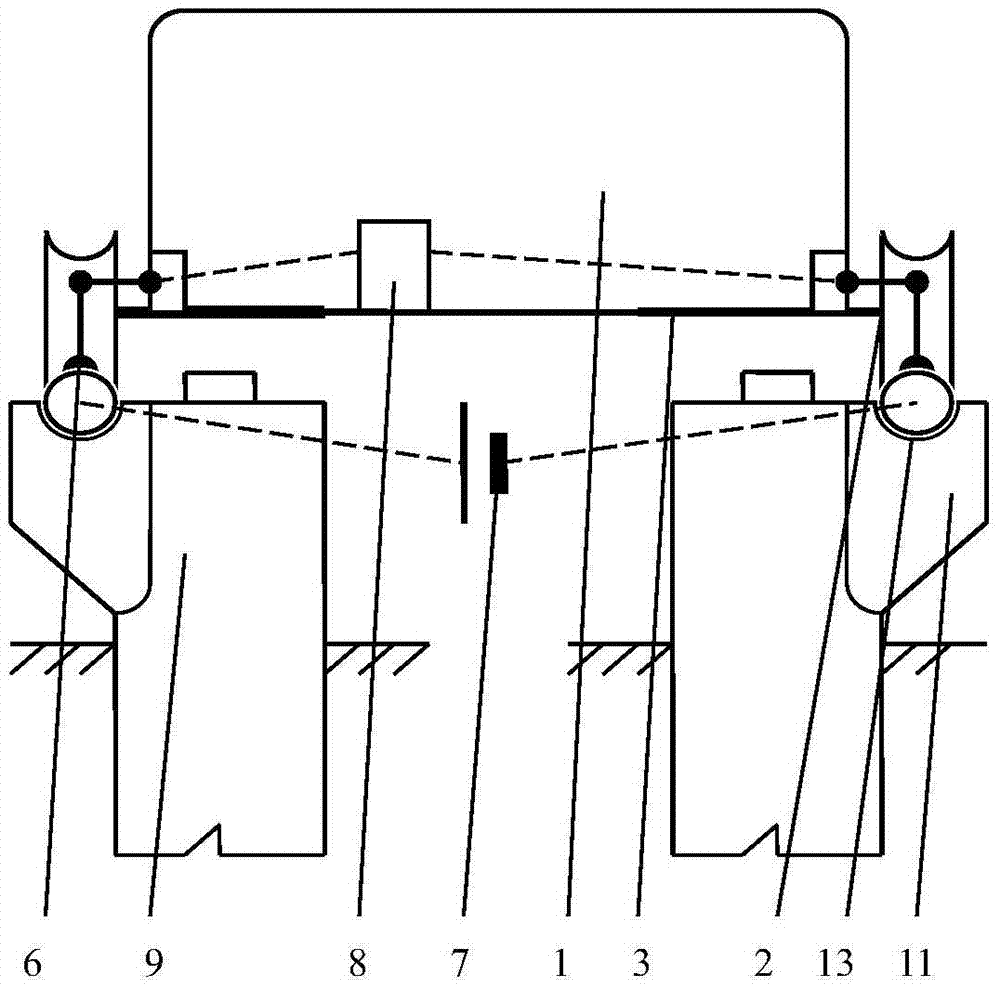

[0015] Embodiment 1, manufacture a track circuit power supply vehicle 1, comprise wheel set 2, chassis frame 3 and computer control system, wheel set 2 and a group of two rails 4 rolling connection; Electrically isolated between them and electrically connected to the track 4 by using the sliding power receiving block 6; a group of two rails 4 is connected to the two electrodes of the power supply 7; power supply 7, a group of two rails 4, the sliding power receiving block 6 and the track loop The electrical consumers 8 of the vehicle 1 form an electrical circuit.

[0016] Both the wheel set 2 and the sliding power receiving block 6 are signal-connected with the computer control system host through an interface circuit; the states of the wheel set 2 and the sliding power receiving block 6 change according to the state of the computer control system host. A group of two rails 4 is arranged on the rail supporting interface 11 of the two rows of foundation piles 9 . The track 4 i...

Embodiment 2

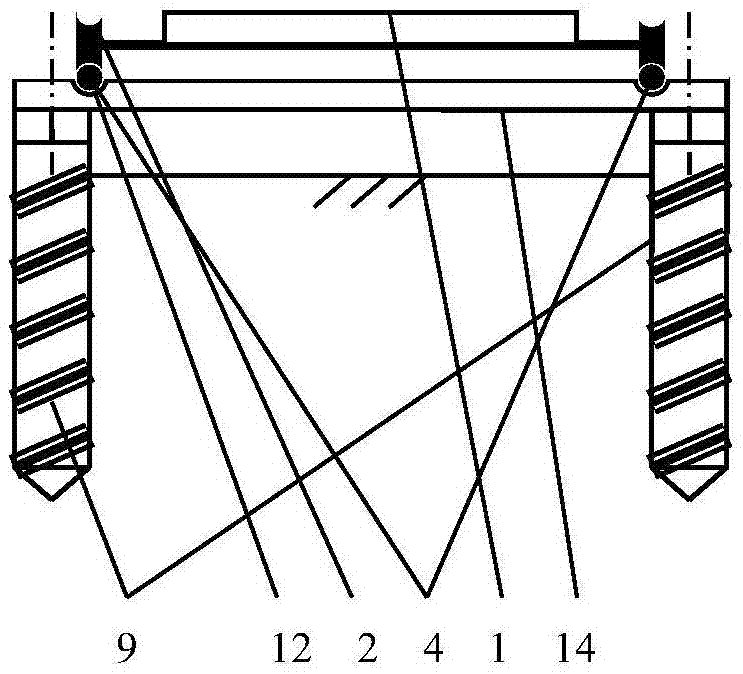

[0018] Embodiment 2, manufacturing a track loop power supply vehicle 1, including wheel set 2, chassis frame and computer control system, wheel set 2 and a group of two tracks 4 rolling connection; between the wheel set 2 on the two tracks 4 Electrically isolated and electrically connected to the track 4 by using the sliding power receiving block; a group of two rails 4 is connected to the two electrodes of the power supply; The load forms an electrical circuit.

[0019] A group of two rails 4 is arranged on a rail supporting interface of a supporting member 14 spanning two rows of foundation piles 9 . The track support interface 11 is a semicircular groove 12 matching the surface of the connected steel pipe track 4 , and the steel pipe track 4 is embedded in the semicircular groove 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com