Special vehicle chassis

A technology of automobile chassis and frame, which is applied in the direction of vehicle components, circuits or fluid pipelines, control devices, etc., can solve the problems of increasing daily maintenance costs, reducing the reliability of the whole vehicle, increasing fuel consumption, etc., so as to improve continuous working time, The effect of reducing modification cost and reducing working fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

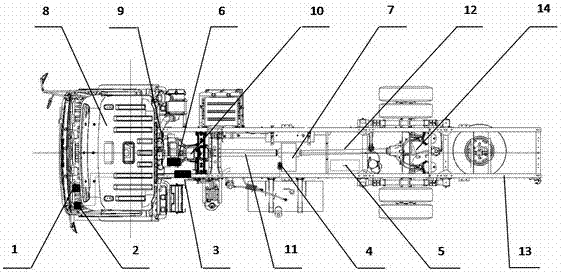

[0018] figure 1 Among them, the present invention includes cab 8, engine 9, full power power take-off 6, gearbox 10, transmission shaft 11, inter-axle reducer 7, rear axle 14, vehicle frame 13, air storage tank 5, solenoid valve 4, driving Computer 3, speed control switch 2 and remote throttle control switch 1. The cab 8 is installed above the vehicle frame 13 front, the engine 9 is installed at the front of the vehicle frame 13, the rear of the engine 9 installed by the full-power power take-off 6, the clutch is installed at the rear of the full-power power take-off, and the gearbox 10 Installed at the rear of the clutch, the inter-axle reducer 7 is installed in the middle of the frame 13, the first drive shaft 11 is connected to the gearbox 10 and the inter-axle reducer 7, the second drive shaft 12 is connected to the inter-axle reducer 7 and the rear axle 14, The PTO1 is connected to the trip computer 3, the speed control switch 2 is connected to the solenoid valve 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com