Image measuring head and image measuring system used for numerical control milling machine

A CNC milling machine and image measurement technology, which is applied in the direction of measurement/indicating equipment, metal processing machinery parts, metal processing, etc., can solve the problems of single point measurement and low measurement efficiency, so as to improve production efficiency, improve accuracy consistency, and replace The effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

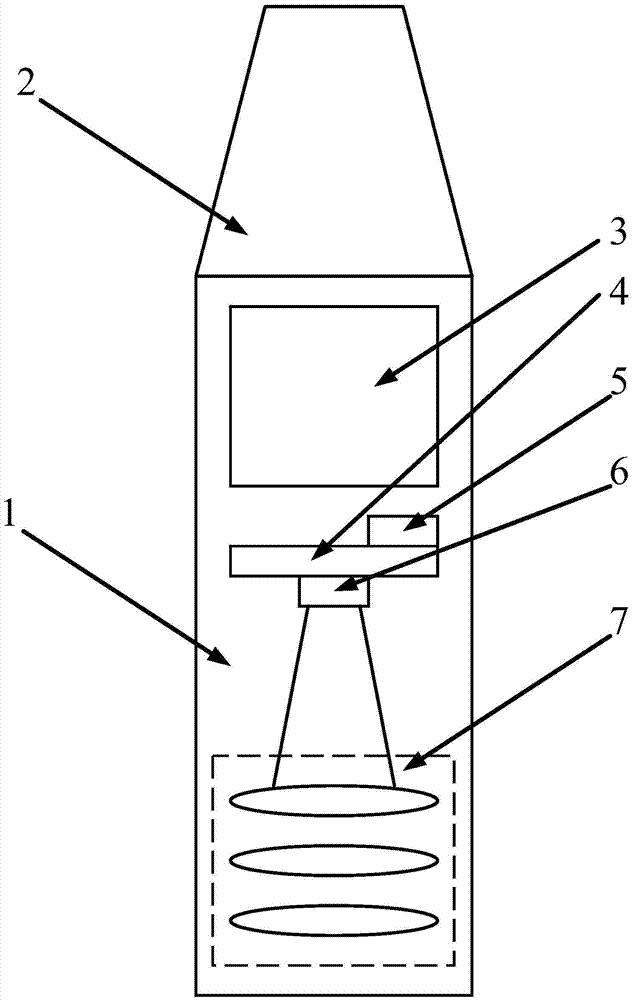

[0023] Such as figure 1 As shown, an image probe 14 for in-situ measurement of a CNC milling machine according to the present invention includes: a housing 1, a coupler 2, a camera module, a communication module 5, and a power supply module 3, wherein the coupler 2 Located at the end of the image measuring head 14, it is fixedly connected with the housing 1, and is used for connection with the spindle tool clamping mechanism of the CNC milling machine; the camera module, the communication module 5, and the power module 3 are arranged in the housing 1; The camera module group includes a camera 6, a lens 7, a camera driver board 4 and an image signal processor (preferably the communication module 5 is arranged on the camera driver board 4), and the power supply module 3 is connected to the camera driver board 4. The group is connected with the communication module 5 to provide electric energy for it. There are many ways to implement the power supply module 3. The battery can be...

Embodiment 2

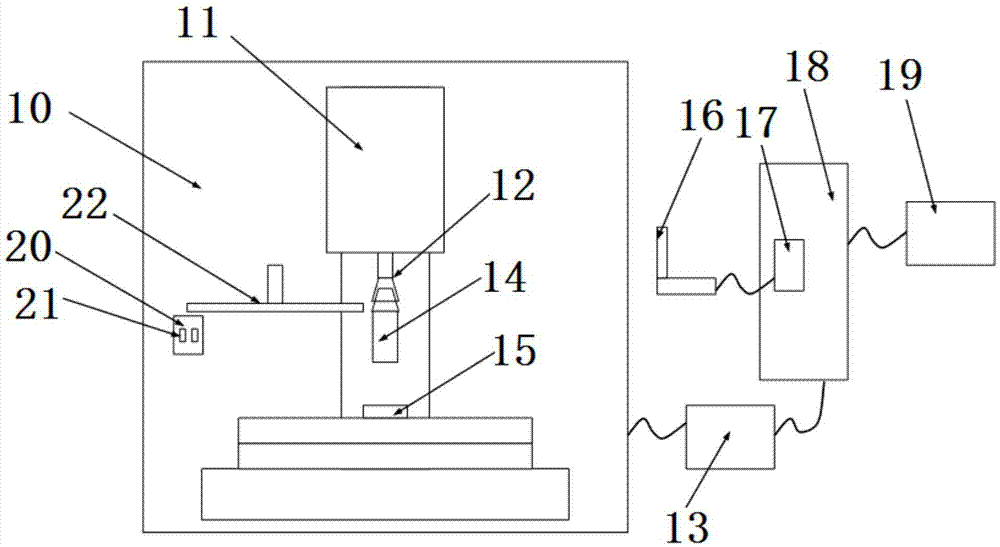

[0029] A video measurement system for in-situ measurement of CNC milling machines, such as figure 2 As shown, it includes a CNC machining center module 10, a control system 13, and a host computer, wherein the CNC machining center module 10 is connected to the control system 13, and performs corresponding detection under the control of the control system 13, and will detect The received image signal is sent to the host, and the host is used to process and display the image signal, wherein the numerical control machining center module 10 includes the image probe 14 described in Embodiment 1, and the image probe 14 is set above the workpiece 15 to be processed.

[0030] Preferably, the CNC machining center module 10 includes a spindle tool clamping mechanism 11, a video probe holder 20, and a video probe loading and unloading hand 22, wherein the video probe 14 is mounted on the spindle tool through a coupling 2. The clamping mechanism 11 is connected (here, the conical surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com