Method for machining metal pipe with tapered elbow

A technology of metal pipes and processing methods, which is applied in the field of material processing, can solve the problems that it is difficult to meet the requirements of metal strength, plasticity and other performance requirements for reducing wall thickness, cannot meet the requirements of parts taper, and cannot use bending methods, etc., to achieve Low cost, good performance, bright surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

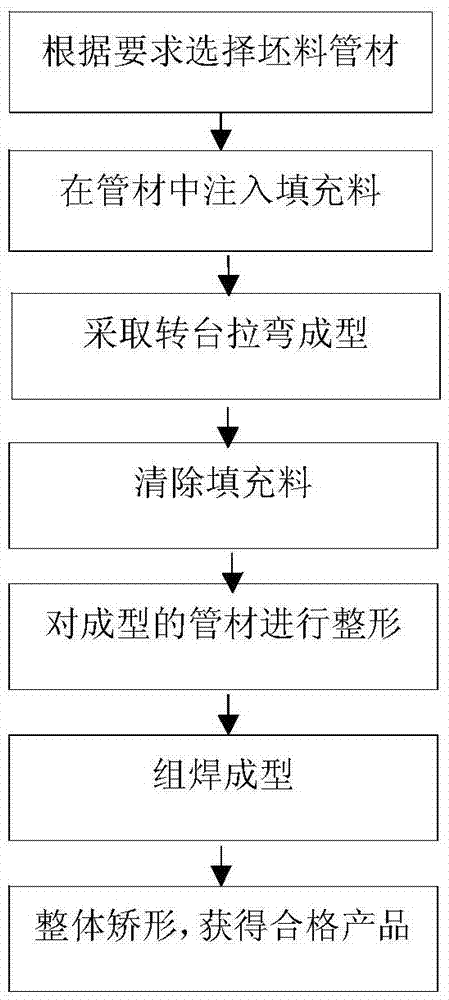

Method used

Image

Examples

Embodiment 1

[0023] Using 304 stainless steel pipes with a cross-sectional major axis of 65 mm, a cross-sectional minor axis of 38 mm, and a wall thickness of 2 mm, a ring with a finished ring diameter of 800 mm and a cross-sectional inclination angle of 15° is made. Use a flexible mold to process pipes using a turntable stretch bending process. The specific operation steps are as follows:

[0024] l) Draw a 304 stainless steel round tube with a diameter of 57 mm and a wall thickness of 2 mm to obtain a tube with a cross-section major axis of 65 mm, a cross-section minor axis of 38 mm, and a wall thickness of 2 mm, with a length of 1656 mm; , cleaning the prepared pipe for later use;

[0025] 2) Inject melted paraffin into the pipe, seal both ends tightly, and set aside;

[0026] 3) Turntable stretch bending processing; the stretch bending mold adopts a flexible mold, the mold groove is consistent with the shape of the pipe section, the shape inclination angle is 15°, the thickness of eac...

Embodiment 2

[0032] A circular ring with a ring diameter of 600 mm and a cross-sectional inclination angle of 5° is made by using a brass material with a blank section length of 55 mm, a blank section width of 38 mm, and a wall thickness of 1.5 mm. Use a flexible mold to process pipes using a turntable stretch bending process. The specific operation steps are as follows:

[0033] l) Select a soft metal tube with a section length of 55mm, a section width of 38mm, a wall thickness of 1.5mm, and a length of 1342mm, and clean it for later use;

[0034] 2) Inject melted rosin into the pipe, seal both ends tightly, and set aside.

[0035] 3) Perform turntable stretch bending processing. The stretch bending mold adopts a flexible mold, the mold groove is consistent with the shape of the pipe section, the shape inclination angle is 5°, the thickness of each unit is 5mm, and the overall mold diameter is 540mm. The blank steel pipe is embedded in the mold, and then the mold and the steel pipe are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com