Mineral separation production line

A production line and mine-used technology, which is applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as insufficient drying, low efficiency, and stuck conveying, so as to achieve unimpeded conveying process and improve the quality of beneficiation , the effect of preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

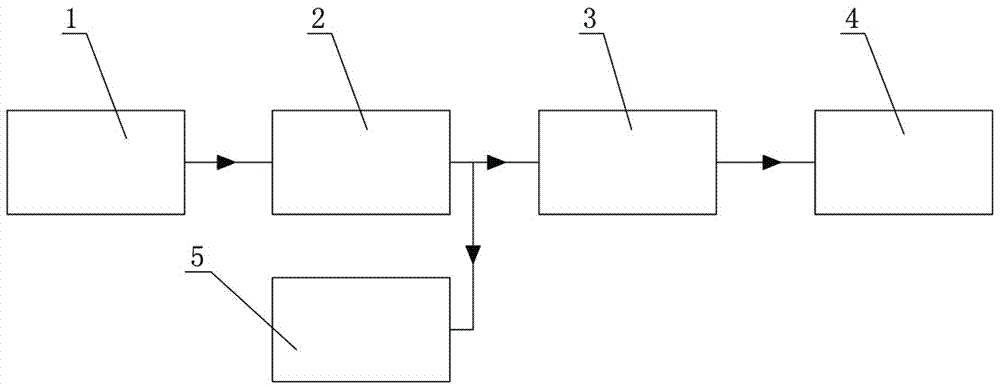

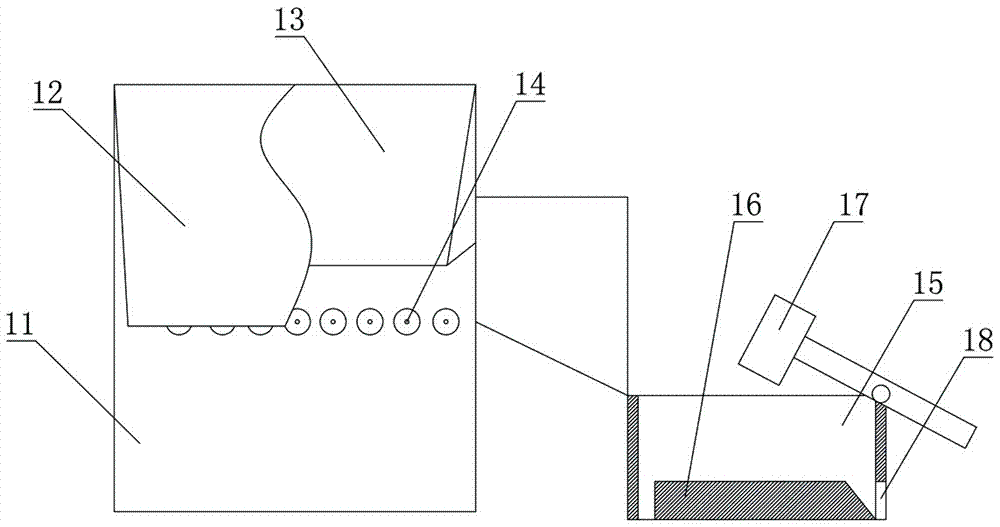

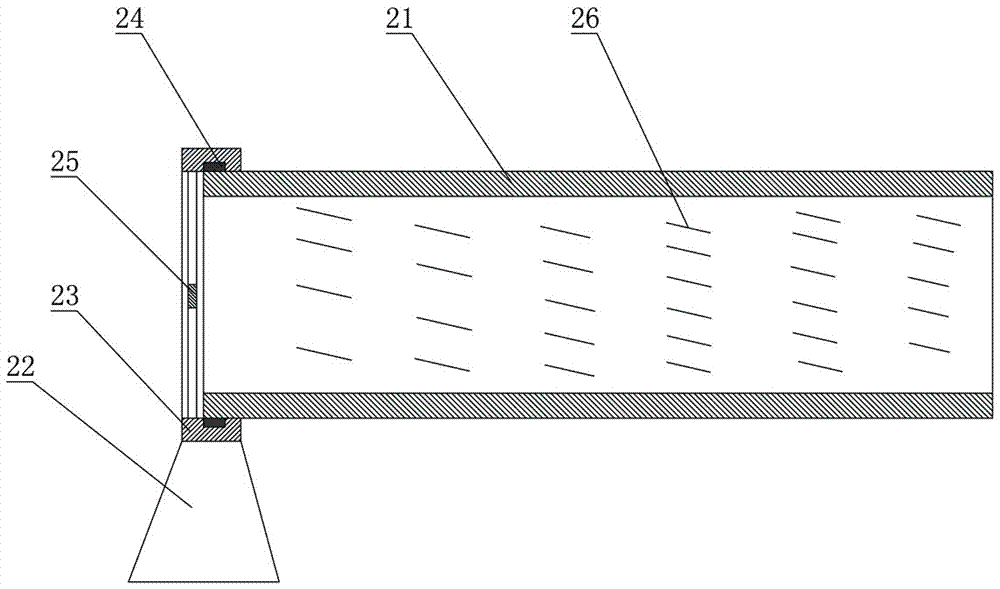

[0028] Such as figure 1 and figure 2 Shown, a kind of mineral processing production line, it comprises the feeder that connects successively, mineral processing with crusher 1, mineral processing with dryer 2, auger conveyer 3, ball mill 4 and corresponding described mineral processing with dryer 2 setting The dust removal device 5 for mineral processing, wherein the crusher for mineral processing includes a flat material removal mechanism, and the discharge end of the flat material removal mechanism is connected to the feed port of the dryer for mineral processing. The flat material removal mechanism includes a plurality of conveying rollers 14 located below the discharge port of the crushing cavity surrounded by the static jaw plate 12 and the movable jaw plate 13 of the mine crusher, and the plurality of conveying rollers 14 The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com