Platinum complex catalyst and its preparation method and use

A platinum complex and catalyst technology, applied in the field of the preparation of the platinum complex catalyst and the synthesis of KH-560, can solve the problems of low KH-560 yield, low catalyst activity, low reaction rate, etc., and achieve shortened induction long-term, high catalytic activity, and the effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a preparation method of the above-mentioned platinum complex catalyst, comprising the following steps:

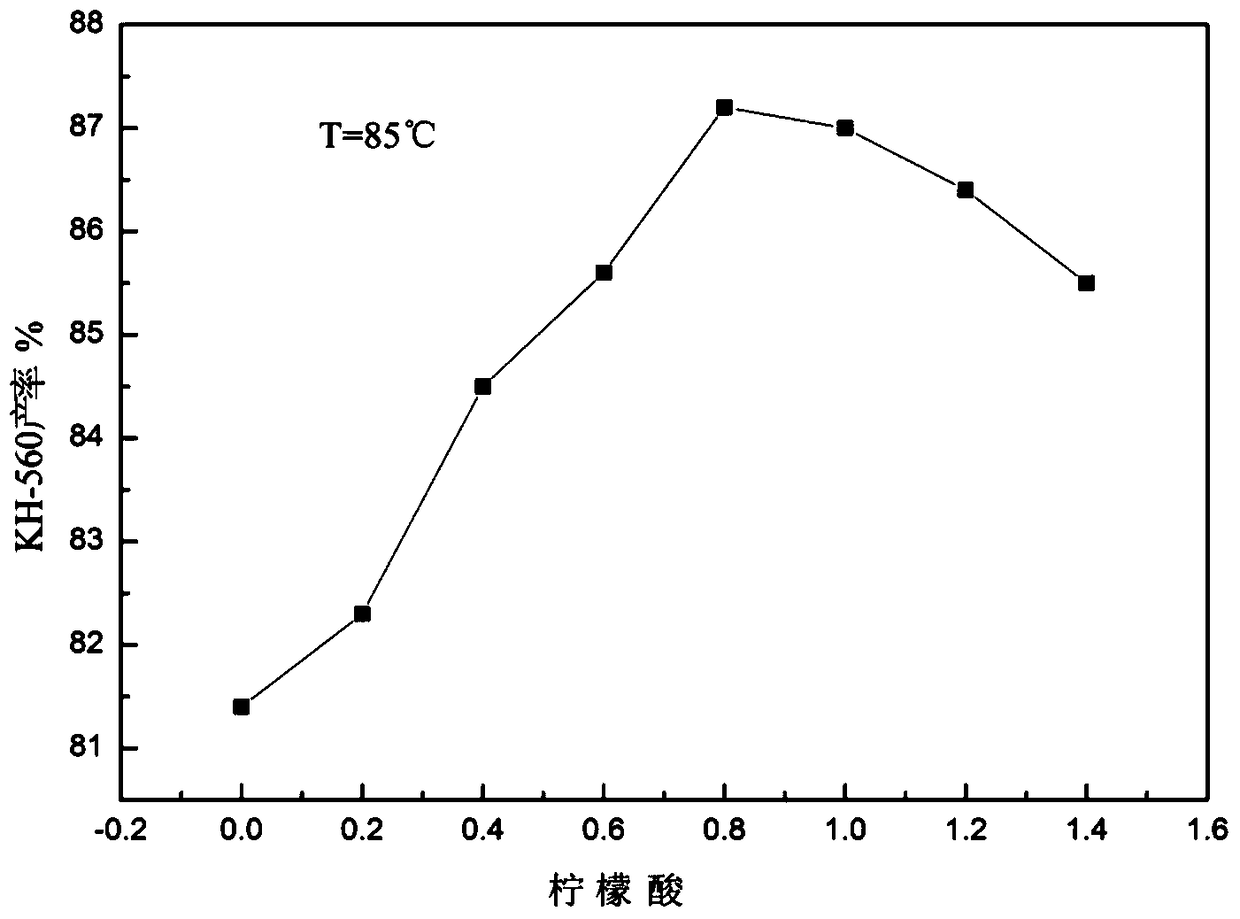

[0032] In a three-necked flask equipped with a stirring bar and a thermometer, add p-hydroxybenzaldehyde, citric acid, chloroplatinic acid hexahydrate, and isopropanol, and dissolve p-hydroxybenzaldehyde, citric acid, and chloroplatinic acid hexahydrate in isopropanol, The molar ratio of p-hydroxybenzaldehyde, citric acid, and chloroplatinic acid hexahydrate is 1.2-1.3:0.8-1:1, stirring at a speed of 200-300rpm, heating in a water bath and raising the temperature to 50°C-60°C, and keeping it for half an hour , to obtain the above-mentioned platinum complex catalyst.

[0033] The preferred molar ratio of p-hydroxybenzaldehyde, citric acid, and chloroplatinic acid hexahydrate is 1.2-1.25:0.8-0.9:1, and the optimum molar ratio is 1.2:0.8:1.

[0034] The above-mentioned platinum complex catalyst was characterized by ...

Embodiment 1

[0047] This embodiment provides a kind of platinum complex catalyst, and this catalyst comprises p-hydroxybenzaldehyde, citric acid, chloroplatinic acid hexahydrate, isopropanol, and p-hydroxybenzaldehyde, citric acid, chloroplatinic acid hexahydrate are dissolved in isopropyl alcohol The molar ratio of alcohol, p-hydroxybenzaldehyde, citric acid and chloroplatinic acid hexahydrate is 1.2:0.8:1.

[0048] The present embodiment also provides the preparation method of above-mentioned platinum complex catalyst, comprises the following steps:

[0049] In a 50ml three-necked flask equipped with a stirring bar and a thermometer, add p-hydroxybenzaldehyde, citric acid, chloroplatinic acid hexahydrate, isopropanol, dissolve p-hydroxybenzaldehyde, citric acid, and chloroplatinic acid hexahydrate in isopropyl The molar ratio of alcohol, p-hydroxybenzaldehyde, citric acid, and chloroplatinic acid hexahydrate is 1.2:0.8:1, stirred at a rate of 200 rpm, heated in a water bath to 50°C, and ...

Embodiment 2

[0053] In this example, except that the amount of catalyst used in the synthesis of KH-560 is 90 μL, the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com