Grit-water separator

A sand-water separation and water storage tank technology, applied in the feeding/discharging device of the sedimentation tank, the sedimentation tank, etc., can solve the problems of large vibration, unstable operation, and the screw conveyor and the water storage tank are not closely matched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

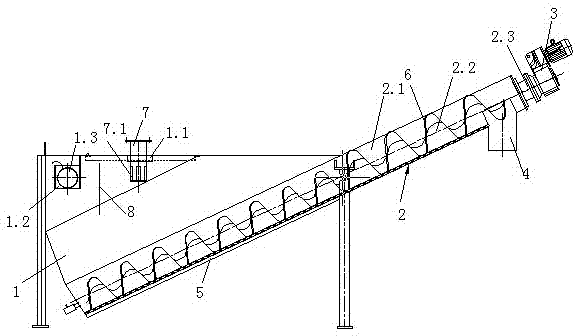

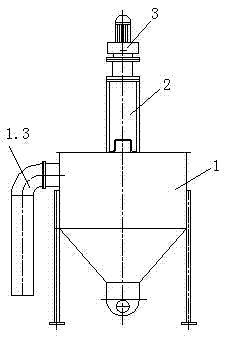

[0010] Embodiment 1: a kind of sand-water separator, comprises the water storage tank 1 that is arranged obliquely upwards, is arranged on the screw conveyor 2 in the water storage tank 1, the upper end of the water storage tank 1 is provided with the water inlet 1.1, and the water storage tank 1 near the top is provided with an overflow Launder 1.2, overflow channel 1.2 is provided with a curved downward overflow pipe 1.3, the screw conveyor 2 includes a U-shaped tank body 2.1 with an open top, and a shaftless spiral blade 2.2 is arranged in the U-shaped tank body 2.1, The top of the spiral blade 2.2 is provided with an output shaft 2.3, the output shaft 2.3 is connected to the driving device 3, one end of the U-shaped tank body 2.1 extends into the water storage tank 1, and the other end extends out of the water storage tank 1 and is provided with a vertically downward discharge Port 4, the inclination angle of U-shaped tank body 2.1 is the same as that of the bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com