Compound bactericide and application thereof

A compound fungicide and additive technology, applied in the direction of fungicide, application, biocide, etc., can solve the problems of not being able to keep up with the speed of germ resistance, high development cost, and long development cycle, and achieve the goal of overcoming and germ resistance. Drug properties, lower production and use costs, crop safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

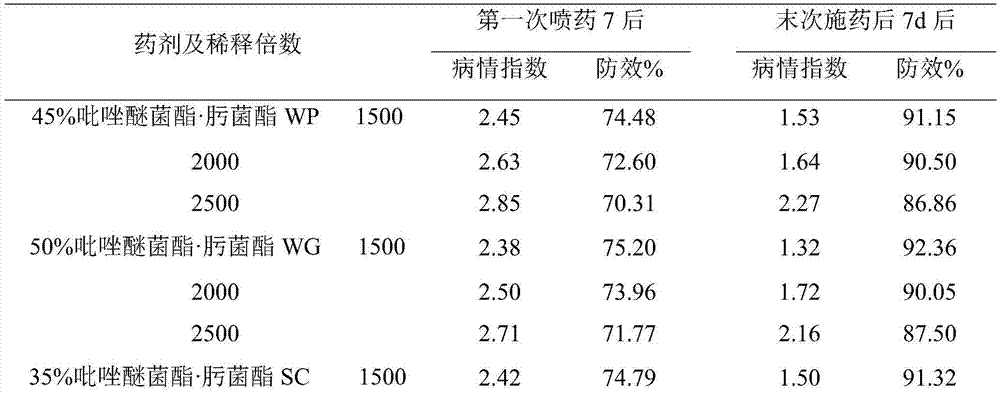

Embodiment 1

[0037] Example 1: (45% pyraclostrobin · trifloxystrobin wettable powder)

[0038] Formula: pyraclostrobin, 30%; trifloxystrobin, 15%; wetting agent sodium lauryl sulfate, 2.5%; dispersant agent calcium lignosulfonate, 6%; filler white carbon black, 8%, Filler Kaolin makes up 100%.

[0039] 2. Water dispersible granules

[0040] Preparation method: according to the formula ratio of the example, add the active ingredients pyraclostrobin and trifloxystrobin into the carrier, and add surfactant and other functional additives, mix, and add 10-25% after jet crushing water, and then kneaded, granulated, dried, and sieved to obtain water-dispersible granules; or the pulverized powder was sprayed with water in a boiling granulator, granulated, dried, and then sieved to obtain the product. The main equipments are mixer, jet mill, kneader, extrusion granulator, drying room or fluidized bed drying, or boiling granulator, screening machine.

Embodiment 2

[0041] Example 2: (50% pyraclostrobin · trifloxystrobin water dispersible granules)

[0042] Formulation: pyraclostrobin, 20%; trifloxystrobin, 30%; wetting agent sodium dodecylbenzenesulfonate, 4%; polycarboxylate, 2%; urea, 4%; polyethylene glycol, 3% dispersant alkyl naphthalene sulfonate formaldehyde condensate, 6%; filler attapulgite to make up 100%.

[0043] 3. Water suspending agent

[0044]Preparation method: according to the proportion of the formula, put the active ingredients pyraclostrobin, trifloxystrobin, surfactant and other functional additives in the reaction kettle in sequence, add water and mix evenly, high-speed shearing, wet sanding, Finally, the product is obtained by homogeneous filtration. The main equipment is batching kettle, colloid mill or homogeneous mixer, sand mill.

Embodiment 3

[0045] Example 3: (35% pyraclostrobin · trifloxystrobin aqueous suspension concentrate)

[0046] Formula: pyraclostrobin, 20%; trifloxystrobin, 15%; dispersant polycarboxylate, 3%; dispersant phosphate, 2%; wetting agent methyl naphthalene xanthate formaldehyde condensate, 1 %; Thickener selection of xanthan gum and magnesium aluminum silicate, the dosage is 0.15% and 2% respectively; antifreeze ethylene glycol, 5%; defoamer organosilicon compound, 0.2%; water, the balance.

[0047] 4. Microemulsion

[0048] Preparation method: Add the active ingredients pyraclostrobin and trifloxystrobin into the carrier according to the formula ratio of the example, and add a surfactant into it, stir in a stirring mixing tank to make it a uniform oil phase, and then slowly stir Add water and stir to become transparent. The stirring and mixing kettle can be enamel reaction kettle, stainless steel stirring kettle, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com