Paste mixing and curing technology for paste-squeezing production of tubular positive plate

A curing process and positive plate technology, used in electrode manufacturing, lead-acid battery electrodes, etc., can solve the problems of workers’ working environment and labor intensity, low battery life, environmental pollution, etc. Eliminate the effect of high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

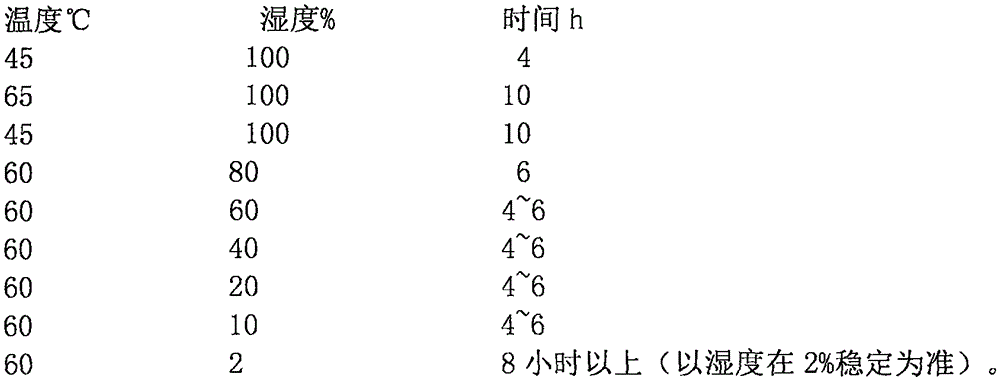

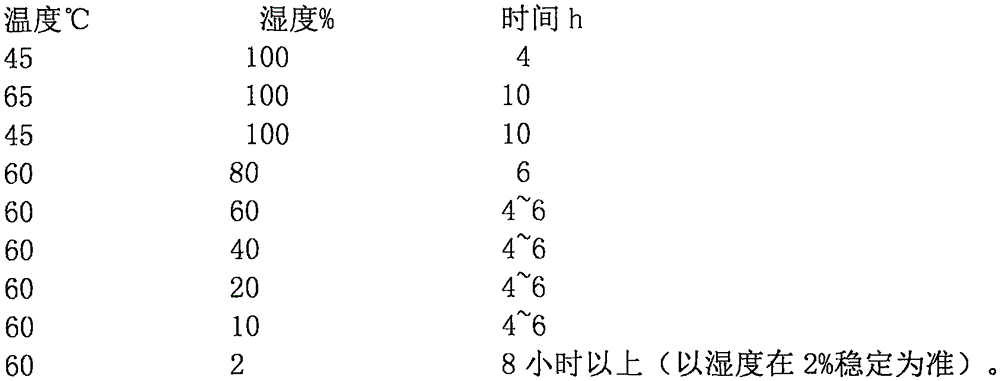

[0014] A paste-squeezing production tube-type positive electrode plate and paste and curing process. This process is suitable for all tube-type positive electrode plate extrusion-type production, and is characterized by:

[0015] 5) Additives: graphite 0.2-0.5%, 0.8-1.2mm long and short fibers 0.6-0.8%, silica sol 1-5%, calcium sulfate 0.25-0.5%, nano-level tetrabasic lead sulfate 0.2-0.4%.

[0016] 6) Lead powder adopts oxidation degree 72~80% and apparent specific gravity 1.2~1.3g / cm 3 Lead powder, sulfuric acid adopts a dilute sulfuric acid solution with a content of 20-25%,

[0017] 7) Ingredients pre-mixing: Pre-mix the formula amount of graphite, long and short fibers, calcium sulfate, nano-level tetrabasic lead sulfate, and 3 to 5% lead powder for 30 minutes;

[0018] 8) Preparation method: First, add the premixed additives in the paste machine, and then add the remaining lead powder. During the process of adding the lead powder, add the lead powder, add water, and stir. The amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com