Coal full-pore-diameter measuring and pore shape semi-quantifying method

A technology of full pore size and pore shape, which is used in measurement devices, suspension and porous material analysis, instruments, etc., can solve problems such as the inability to reflect the true value of coal seam gas content, the inability to obtain the full pore size distribution of coal, and the damage of pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

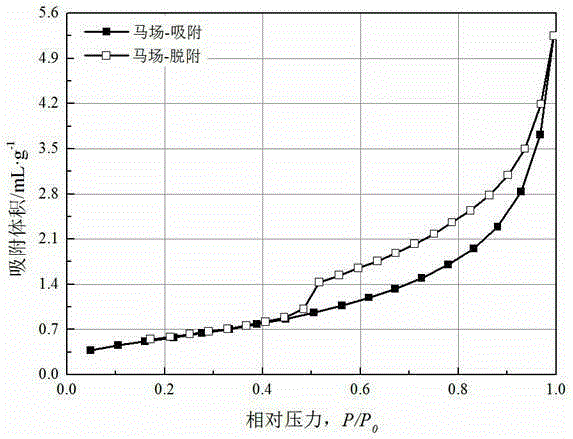

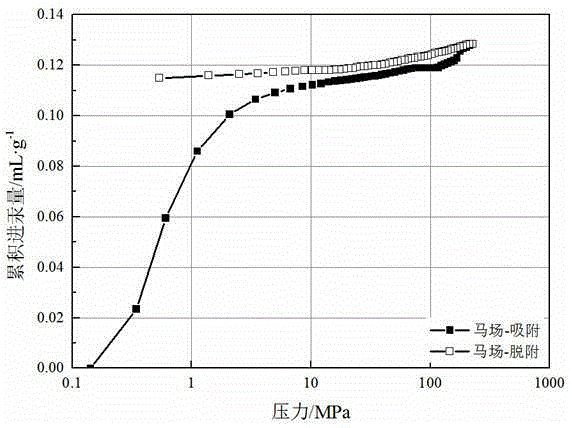

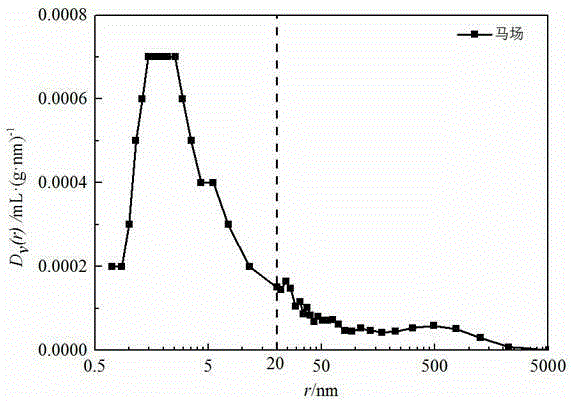

[0038] attached Figure 1~4 The example shown is the Machang Coal Mine in Guizhou, and the specific steps are as follows:

[0039] Specific steps are as follows:

[0040] A coal pore diameter measurement and its pore shape semi-quantitative method: comprising the following steps:

[0041] Step 1. Measurement of coal pore structure by liquid nitrogen adsorption method: SSA-4200 pore and specific surface area analyzer produced by Biod Company was used to conduct low-temperature liquid nitrogen adsorption experiment. The principle of measuring pore distribution characteristics is equivalent volume substitution method, that is, The amount of liquid nitrogen filling in coal pores is the pore volume. According to the principle of capillary condensation, at different relative pressures p / p 0 The range of pore sizes where capillary condensation occurs is different. The pore size at which condensation occurs varies with p / p 0 increases with increasing, for a given relative pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com