Viscometer

A viscometer, hollow technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of unfavorable bearings, damage, liquid infiltration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

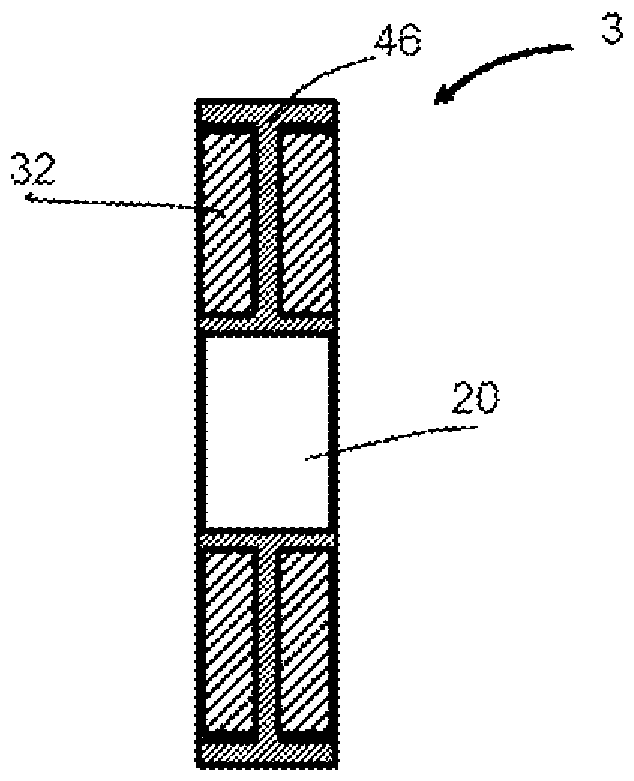

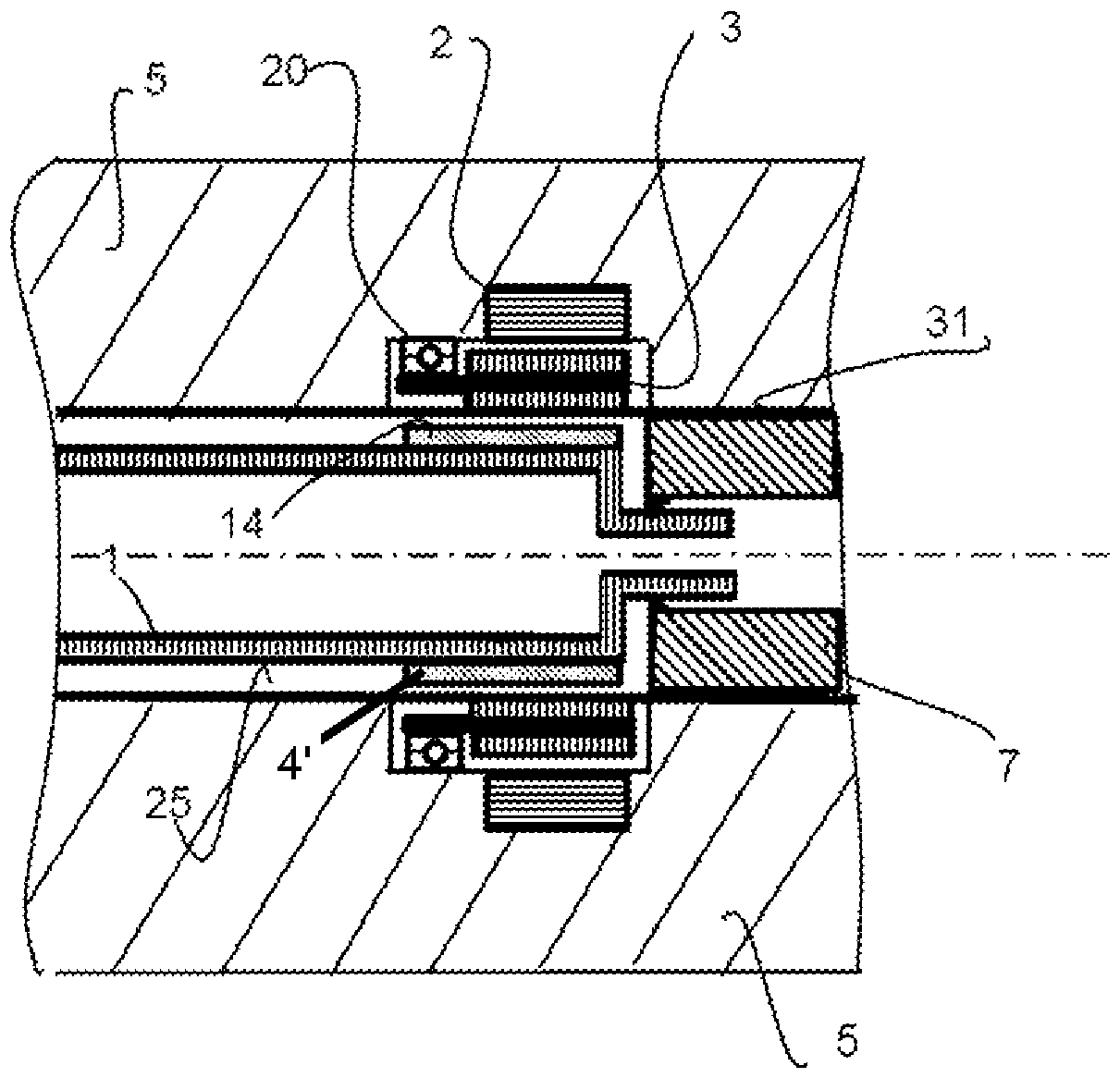

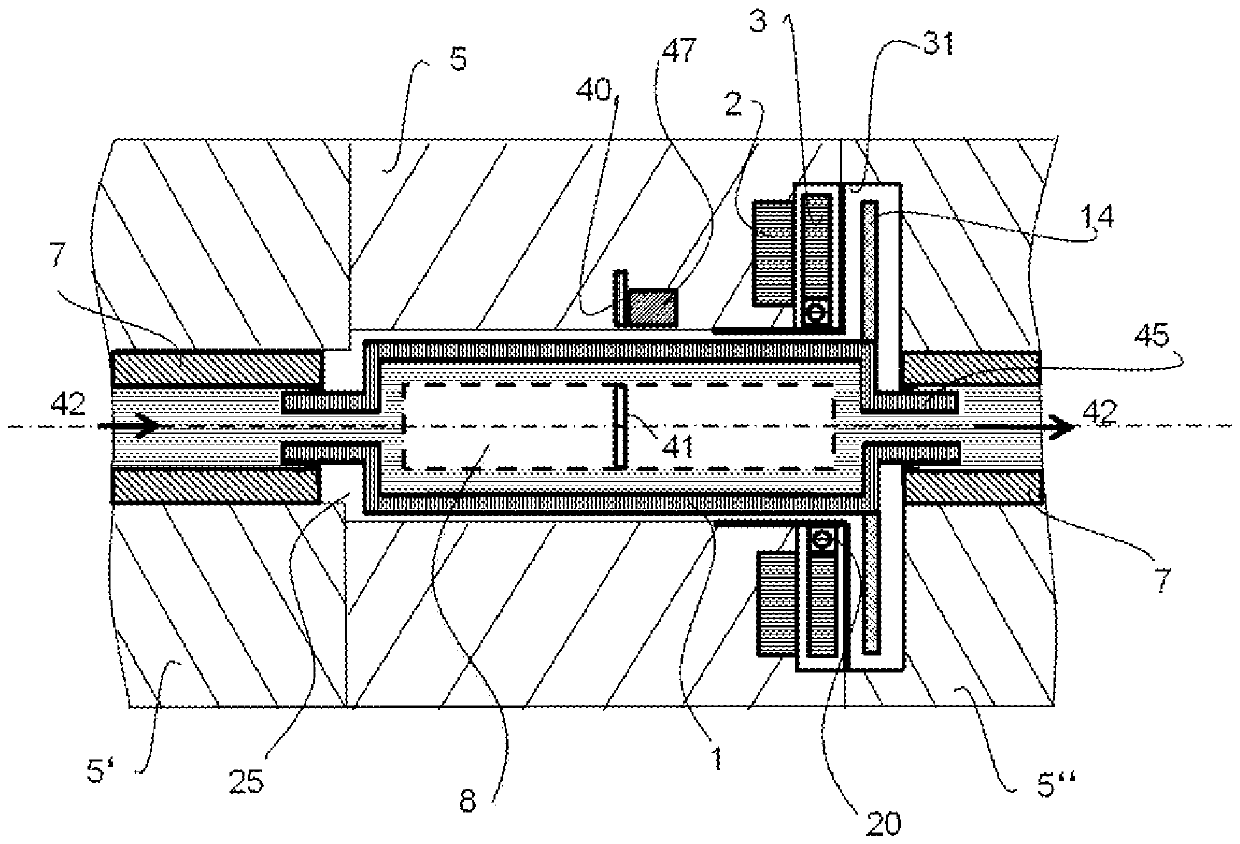

[0027] Such as figure 1 Schematically shown, the viscometer according to the invention comprises a base 5 in which an advantageously cylindrical receiving space or hollow space 25 is formed, which contains the hollow cylinder 1 therein. As already mentioned, the hollow cylinder 1 does not have to have a cylindrical shape; the outer surface or generatrix can also be inclined, so that other geometries can be used, especially those that are rotationally symmetrical to the longitudinal axis of the hollow cylinder 1 geometry.

[0028] The hollow cylinder 1 is supported in fluid-tight bearings 7 in the region of its ends. For this purpose, a socket 45 is attached or integrally formed at the end region or end surface of the hollow cylinder 1 and is used to support the hollow cylinder 1 in the bearing 7 . These sockets 45 allow the measurement fluid to pass through the hollow cylinder 1 , for example in the direction of the arrow 42 .

[0029] Advantageously, a rotationally symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com