Oil cylinder

An oil cylinder and cylinder block technology, which is applied in the field of oil cylinders with adjustable stroke distance, can solve the problems of inability to adjust the stroke and installation distance, use limitations, and damage to the piston rod, so as to avoid interfering force, reduce damage, and improve flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

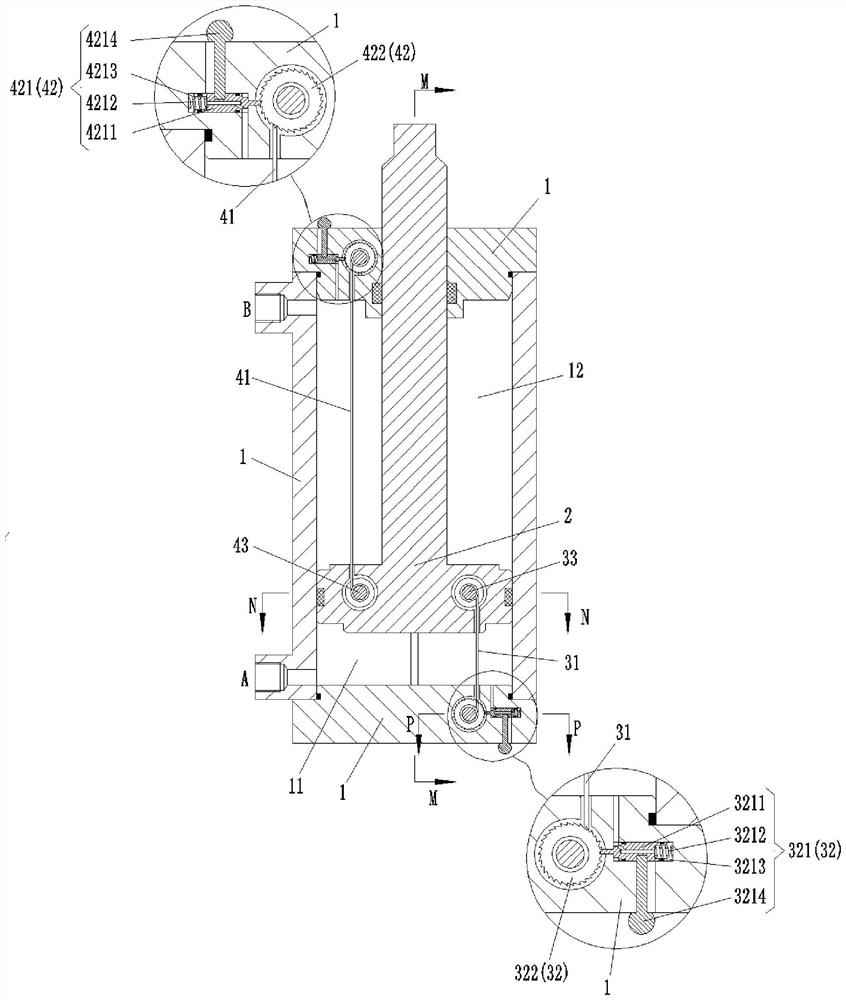

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

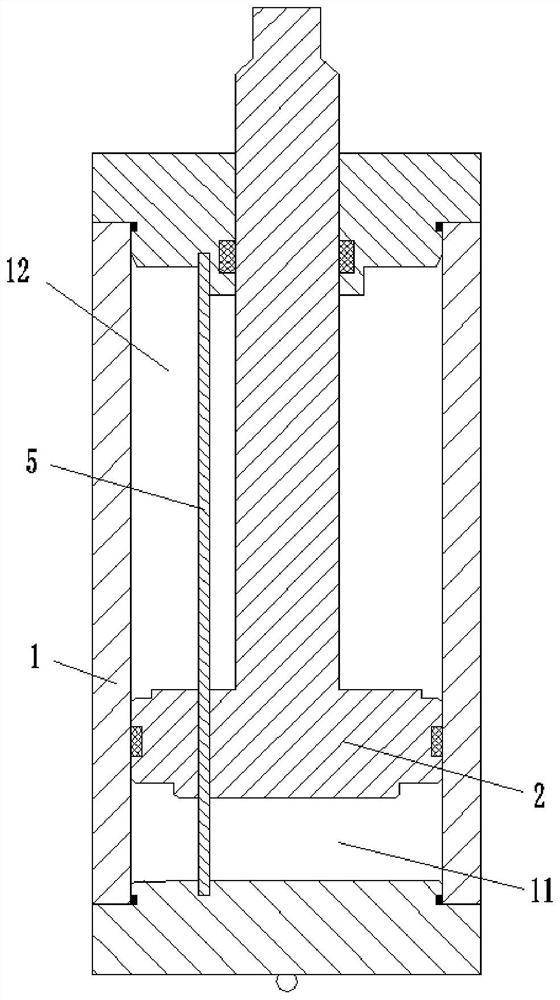

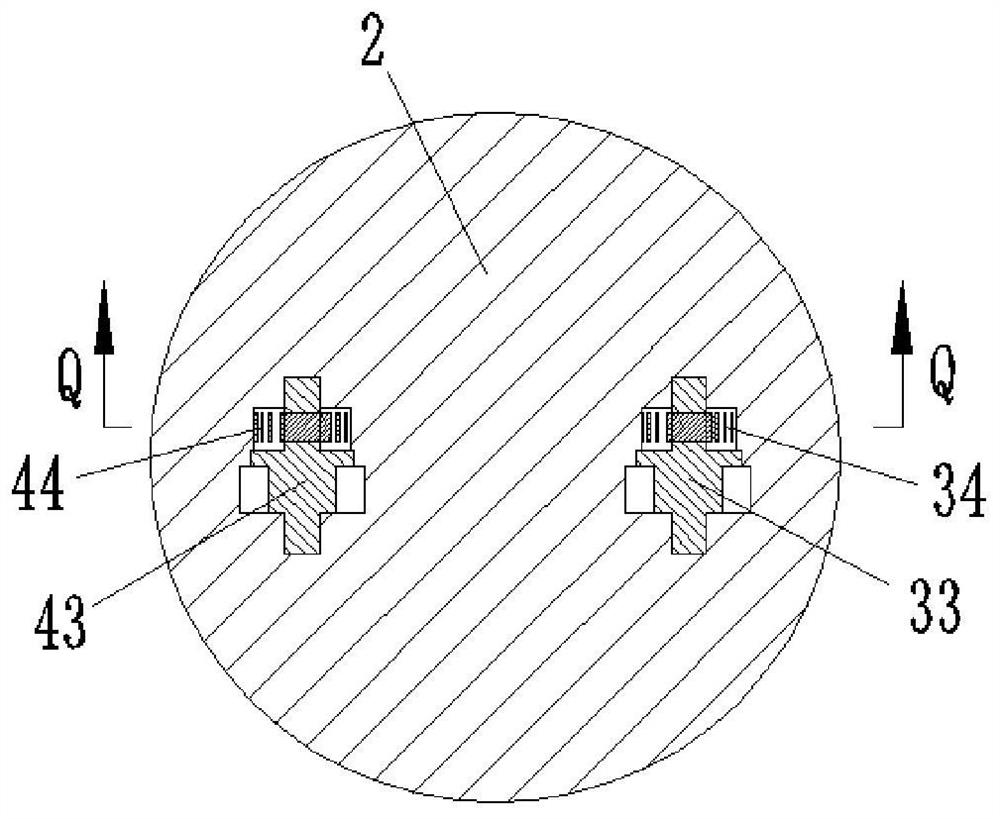

[0025] combine figure 1 As shown, the oil cylinder of this embodiment includes a cylinder body 1, a piston 2, an extension stroke adjustment assembly and a retraction stroke adjustment assembly. Wherein, the cylinder body 1 is provided with port A and port B respectively connected with different pipelines, the piston 2 is located inside the cylinder body 1, and divides the interior of the cylinder body 1 into the first control chamber 11 and the first control chamber 11 which are not connected to each other. The second control chamber 12, the first control chamber 11 is in communication with port A, and the second control chamber 12 is in communication with port B. At this time, the piston 2 acts on the medium pressure between the first control chamber 11 and the second control chamber 12 Next, reciprocating motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com