Resonant-type fiber-optic gyroscope with adjustable sensitivity

A fiber optic gyroscope and sensitivity technology, which is applied in Sagnac effect gyroscopes and other directions, can solve the problems of fixed sensitivity, small dynamic range, and difficulty in measuring rotation speed in a large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

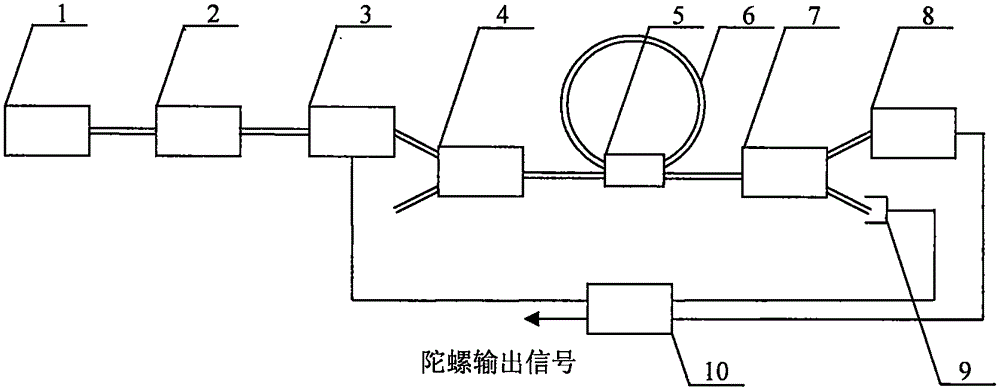

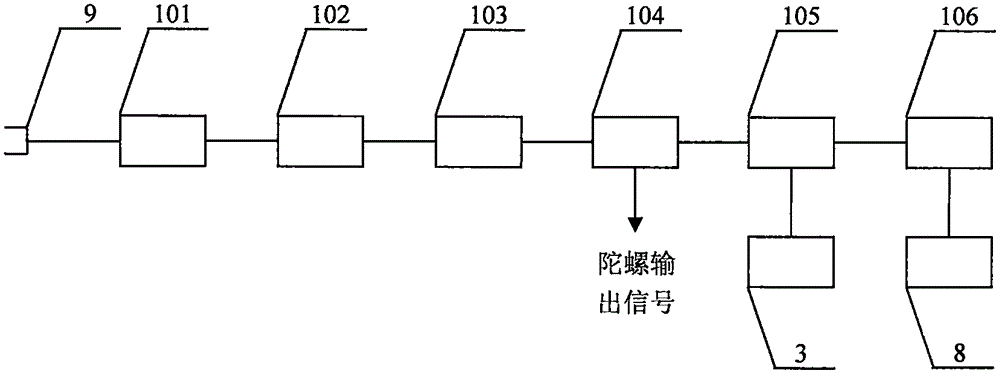

[0017] Such as Figure 1-2 As shown, a resonant fiber optic gyro with adjustable sensitivity includes a first laser 1, a polarization controller 2, a lithium niobate phase modulator 3, a first wavelength division multiplexer 4, a fiber coupler 5, an erbium-doped optical fiber Ring 6, second wavelength division multiplexer 7, second laser 8, detector 9 and signal processing and feedback system 10; the optical output end of the first laser 1 is connected to the optical input end of the polarization controller 2, and the polarization controller The optical output end of 2 is connected with the optical input end of the lithium niobate phase modulator 3, and the optical output end of the lithium niobate phase modulator 3 is connected with the optical input end of the first wavelength division multiplexer 4, and the first wavelength division multiplexer The optical input and output end of the device 4 is connected with the first optical input and output end of the fiber coupler 5, t...

Embodiment 2

[0021] The working principle of the present invention is: the 1550nm laser with constant output power of the first laser device 1, the 1550nm laser enters the polarization controller 2, enters the lithium niobate phase modulator 3 after selecting the polarization state in the polarization controller 2, and enters the lithium niobate phase modulator 3 in the lithium niobate phase The optical frequency is modulated in the modulator 3, and the 1550nm laser light output by the lithium niobate phase modulator 3 enters the first wavelength division multiplexer 4, then enters the erbium-doped fiber ring 6 through the fiber coupler 5, and passes through the fiber coupler 5 and Resonance occurs in the erbium-doped fiber ring 6. After the 1550nm laser resonates, it enters the detector 9 through the second wavelength division multiplexer 7 and is detected by the detector 9. The output signal of the detector 9 enters the signal processing and feedback system 10 for signal processing. Proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com