Steam quantity precisely controlled steam generating device for automobile test

A technology for steam generating device and automobile test, which is applied to steam generation, steam generating method, lighting and heating equipment, etc., can solve the problems of unsuitability for automobile defogging and defrosting test, complicated work flow and high price, and achieves easy realization. , the working principle is simple, the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

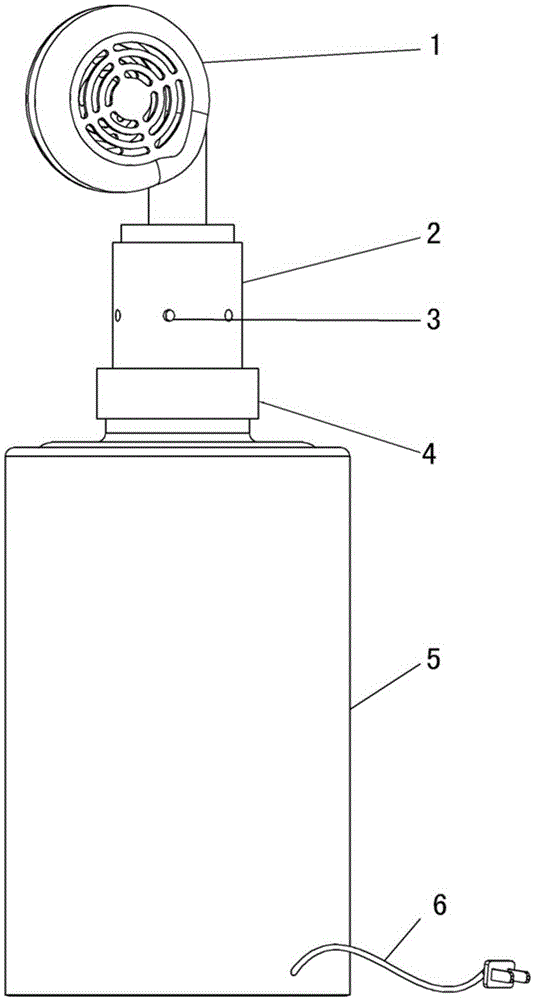

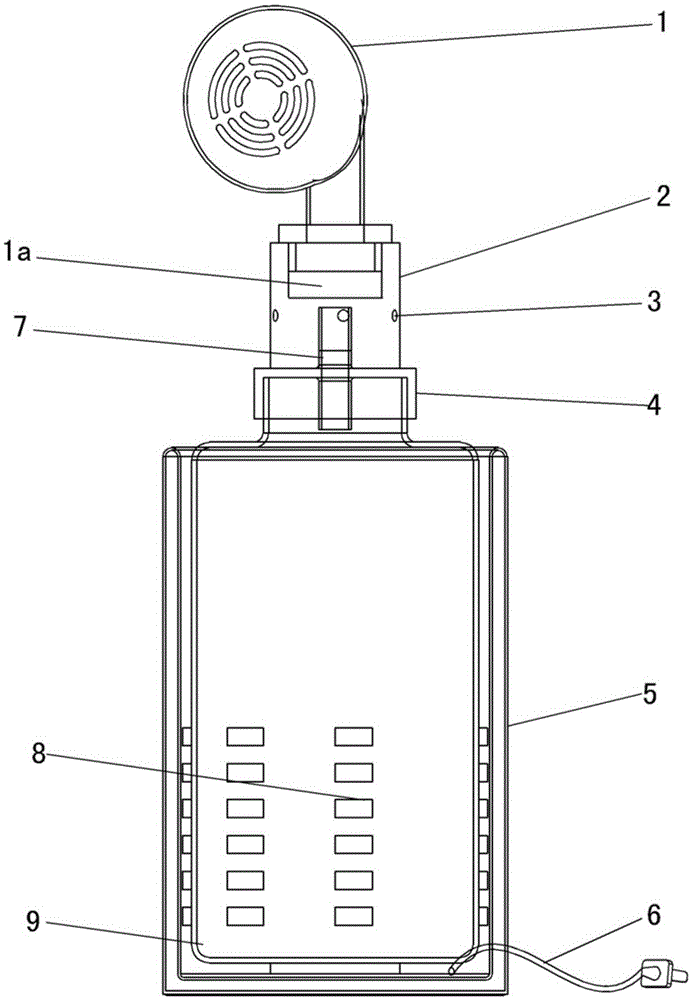

[0029] In this example, if figure 1 and figure 2 As shown, a steam generating device for automobile testing with precise and controllable steam volume includes: a centrifugal fan 1, a diffusion chamber 2, a sealing cover 4, an insulating water storage tank 5, power wiring 6 and a PTC heater 8;

[0030] The centrifugal fan 1 is provided with an air inlet and an air outlet 1a; a diffusion chamber 2 is set on the air outlet 1a of the centrifugal fan 1; six steam exhaust holes 3 with a diameter of 6.3mm are evenly distributed at the lower end of the diffusion chamber 2 ;

[0031] The bottom of the diffusion chamber 2 is connected with a sealing cover 4; the sealing cover 4 is set on the water injection port at the upper end of the insulating water storage tank 5; there is a round hole in the center of the sealing cover 4, and a nozzle 7 is arranged in a round hole, formed by the nozzle 7 The gas circulation channel between the diffusion chamber 2 and the insulating water storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com