Efficient bearing grease injecting device

A grease injection device and bearing technology, which is applied to bearing components, shafts and bearings, engine components, etc., can solve the problems that are difficult to popularize, affect the performance of bearings, and the amount of grease injection is difficult to guarantee, and achieve convenient disassembly, maintenance, cleaning, and grease injection The amount is kept uniform to ensure the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

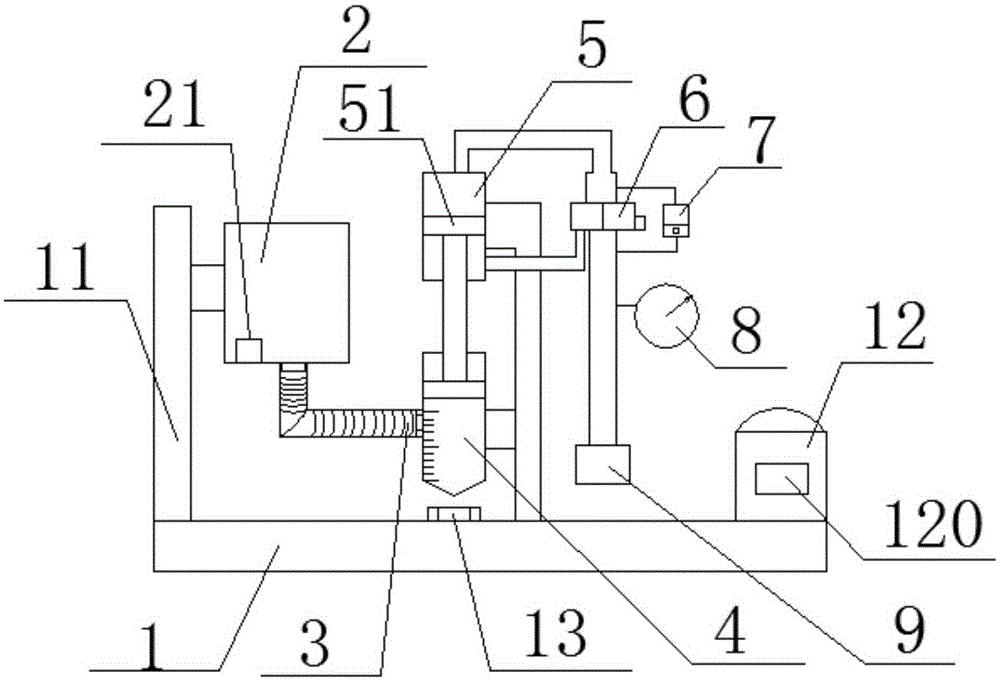

[0015] refer to figure 1 , a high-efficiency bearing grease injection device of the present invention includes a workbench 1, a lubricating grease bucket 2, a grease gun 4, a cylinder 5, a solenoid valve 6, a pressure gauge 8, and an air supply device 9. The workbench 1 is provided with Bearing grease injection tank, several fixed mounts 11 are installed on the workbench 1, and the control box 12 is fixed on the workbench 1. The control box 12 is provided with a control device 120 and a power supply. The control device 120 and the power supply are connected by wires. The lubricating grease bucket 2 is installed on the fixed frame 11, the bottom of the lubricating grease bucket 2 is provided with a temperature regulating device 21, the lower end of the lubricating grease bucket 2 is provided with a grease outlet, and the grease injection gun 4 is provided with a grease inlet. 4 and the lubricating grease barrel 2 are connected by an oil delivery pipe 3, the cylinder 5 is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com