One-way conduction fluid sensor

A fluid sensor, one-way conduction technology, applied in the field of sensors, can solve the problems of water leakage in the casing, large resistance of the partition, and enlarged gap, and achieve the effect of preventing reverse flow, low production cost, and small fluid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

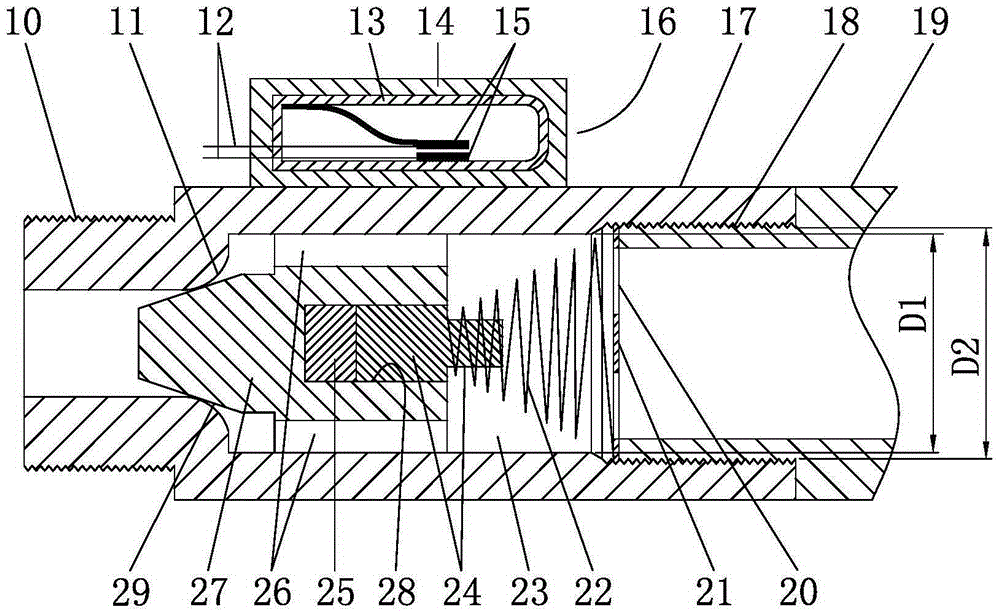

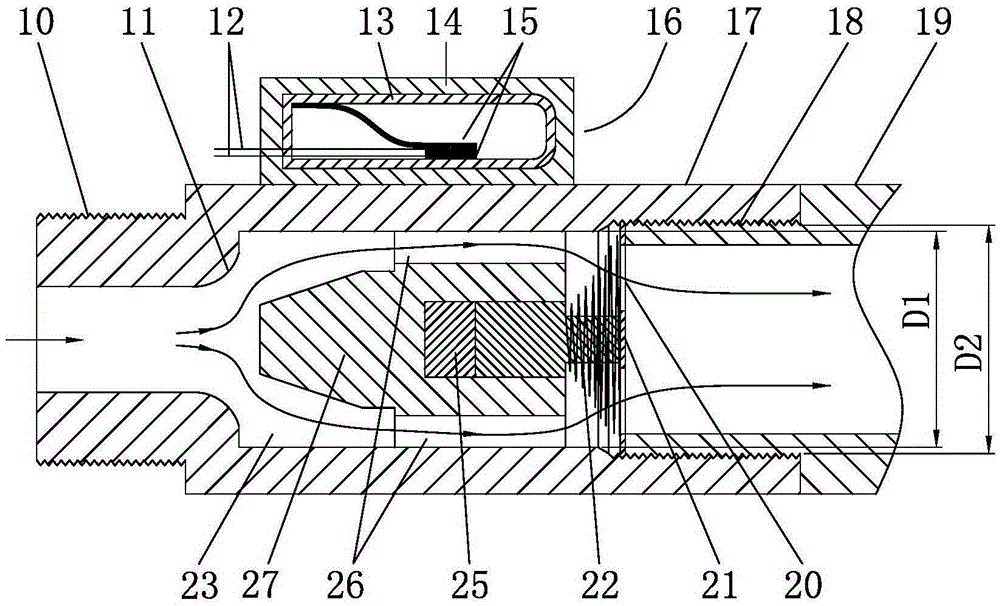

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — figure 2 :

[0024] A kind of one-way conduction fluid sensor, a valve seat 11 is provided on the inner wall of one end of the housing 17 with a fluid channel, and a valve core 27 embedded with a magnetic block 25 and controlling forward conduction and reverse cut-off is provided on the valve seat 11, The tail of the valve core 27 is provided with a limit rod 24, the tail end of the limit rod 24 points to the other end of the housing 17, and the inner wall of the other end of the housing 17 is provided with a limit spring seat 21 with a fluid through hole 20, One side of the return spring 22 is sleeved on the limit rod 24, and the other side is connected to the limit spring seat 21. The outer wall of the housing 17 is provided with a valve core 27 that is opened or closed by the magnetic force of the magnetic block 25. Closed magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com