Well drilling method and device through hydraulic power and disc spring coupling driving and axial vibration

A technology of axial vibration and hydraulic pulse, which is applied in vibration drilling and other directions, can solve the problems of low reliability, complex structure, and inability to be popularized on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

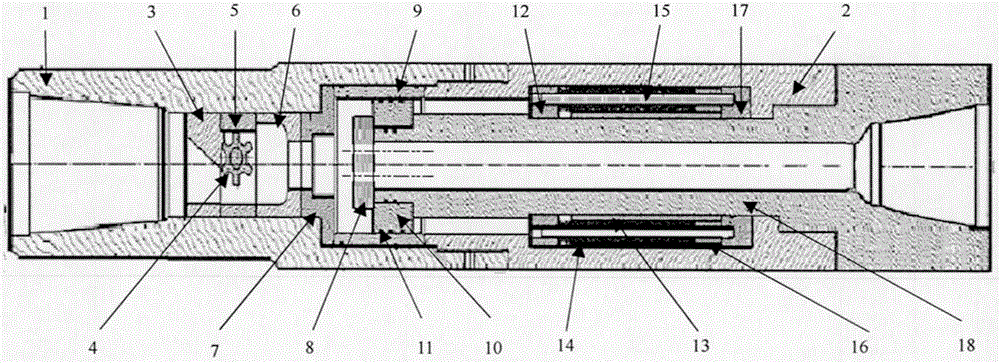

[0018] figure 1 It is a schematic diagram of the assembly of the disc spring of the present invention in its natural state. The present invention includes a body, a pulse generator and an axial vibration device. The main body is composed of an upper tube (1) and a lower tube (19), which are connected by male and female buckles. The pulse generator is composed of the guide fluid (3), the impeller seat (5), the impeller and the impeller shaft (4), the vibrating nozzle (6), and the nozzle seat (7). When installing, install the impeller and the shaft (4) on the impeller seat (5), then install the guide fluid (3), the impeller seat (5), the vibrating nozzle (6), and the nozzle seat (7) in the upper cylinder (1) in sequence. The axial vibration device is composed of a pressure bearing surface (8), a piston part, a disc spring part, and a central rod (18); the piston part from the inside to the outside is the piston (10), the oil seal (11), and the piston sleeve (9) When installing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com