Automatic-oiling rotating shuttle shaft structure and rotating shuttle box of embroidery machine

A technology of automatic refueling and hook shaft, which is applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc. It can solve the problems of hook shaft jamming, wrong filling time, and high manual maintenance costs, so as to reduce waste and Pollution, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

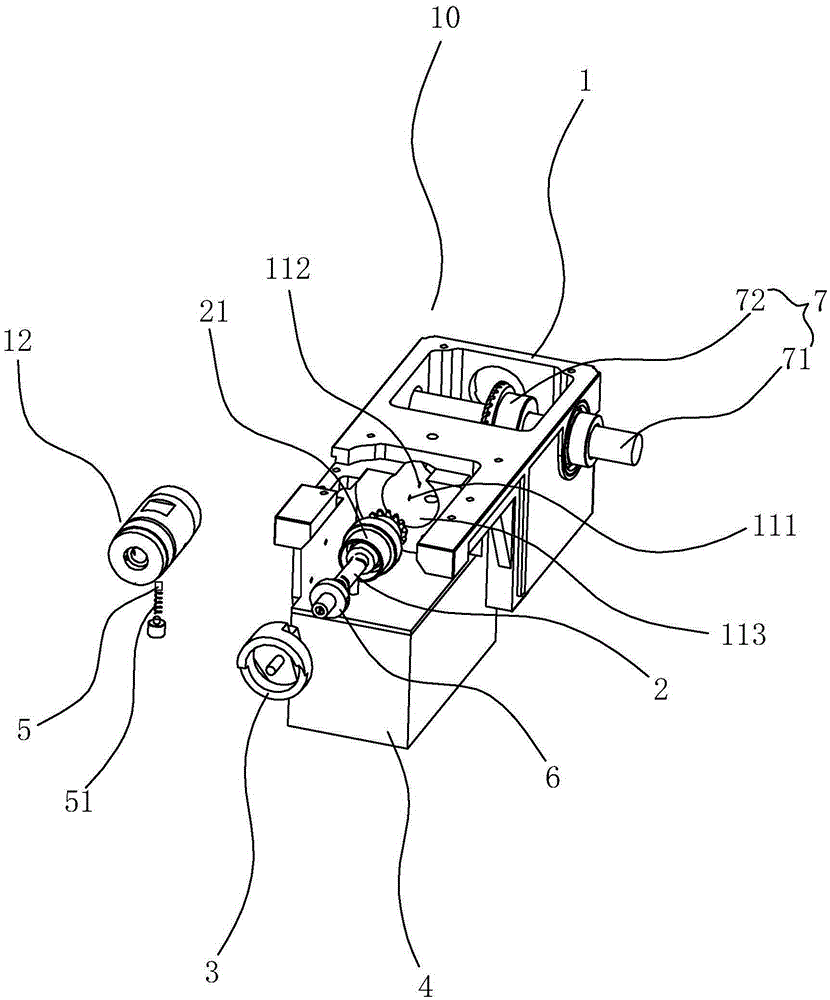

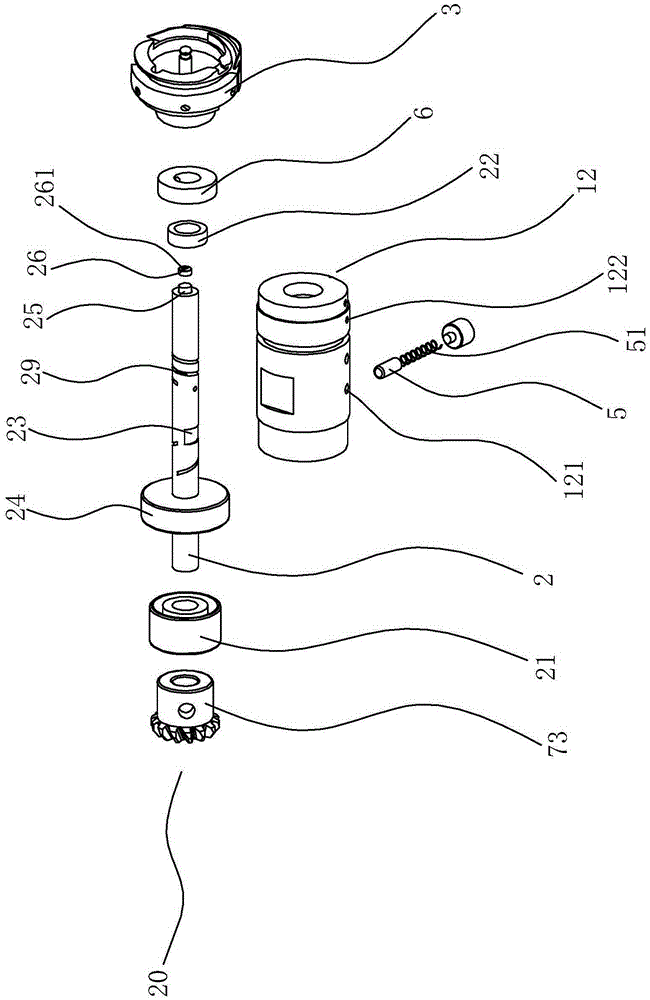

[0043] Such as figure 1 As shown, a rotary hook box 10 of an embroidery machine comprises a rotary hook box 1, a rotating shaft 2 connected to the rotary hook box 1 by transmission, a rotary hook 3 connected to the rotary shaft 2 by transmission, a lubricating oil tank 4, a piston column head 5, and a piston The elastic member 51, the left oil seal 21 and the right oil seal (combined with figure 2 ), for pressing the right oil seal (combined figure 2 ), the positioning retaining ring 6, the power unit 7 fixed on the hook box 1.

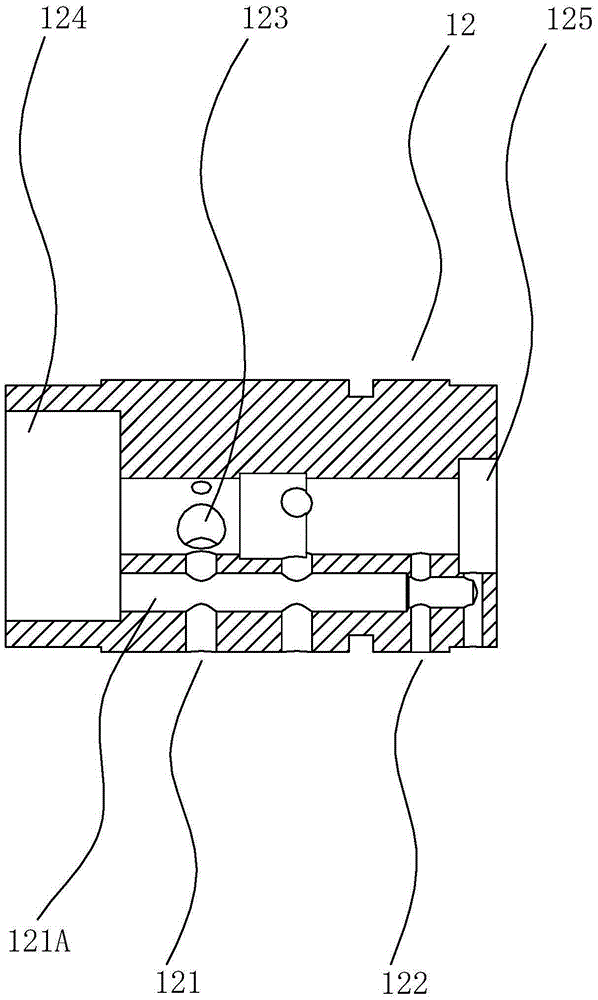

[0044] The hook box 1 includes a box body 11 and a sleeve 12 sleeved on the outer periphery of the rotating shaft 2 . The casing 11 is provided with an oil inlet pipeline 111 and an oil outlet pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com