Pneumatic injector used for micro-operation robot system

A robot system and syringe technology, applied in biochemical instruments, methods of sampling biological materials, biochemical equipment and methods, etc., can solve the problems of linearity, stability and repeatability of air pressure, unfavorable pressure value analysis and control, etc. , to achieve the effects of improved test stability, stable air pressure, good linearity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

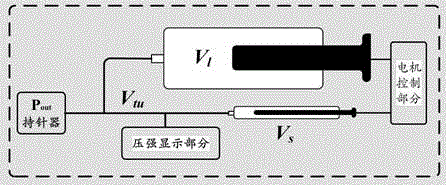

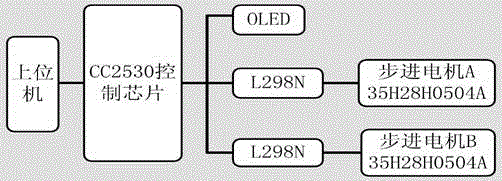

[0031] Such as Figure 1 to Figure 3 As shown, the pneumatic injector for the micro-operation robot system provided by the present invention mainly includes the following three parts: 1) the air circuit part; 2) the mechanical structure part; 3) the air pressure display and the motor control part;

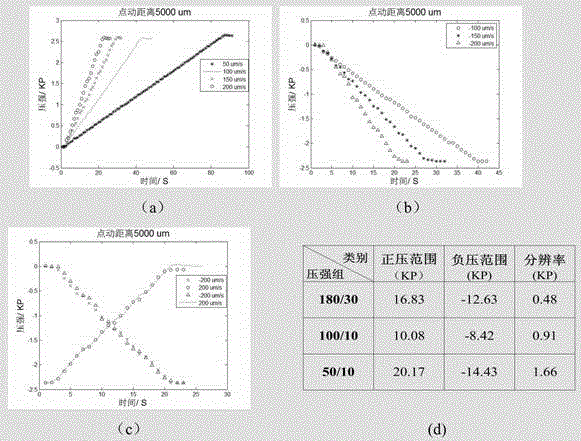

[0032] First, the gas circuit part includes: a small syringe and a large syringe connected to each other by a connecting pipe and a joint. After the pressure accumulation of the large syringe, the volume change of the small syringe causes a small pressure change, thereby improving the resolution;

[0033] For specific operations, prepare the required types of syringes, connecting tubes, connectors, etc., such as but not limited to spiral syringes, 1 / 16inch silicone tubes, Luer connectors, etc.; connect the basic materials as needed (see figure 1 ). Among them, the joint is preferably one model larger than the hose.

[0034] Second, the mechanical structure part: as attached fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com