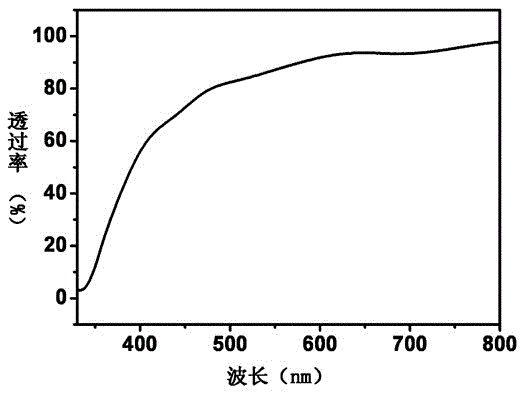

Bismuth-molybdate-based transparent ferroelectric light-emitting film and preparation method thereof

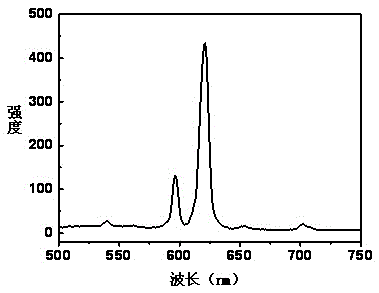

A light-emitting film, bismuth molybdate technology, applied in the direction of light-emitting materials, chemical instruments and methods, to achieve the effect of good photoluminescence characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

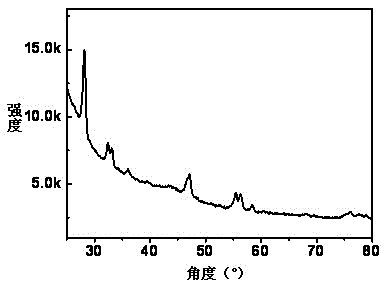

[0035] This embodiment provides a bismuth molybdate-based transparent ferroelectric light-emitting film, the chemical composition of which is (Bi 1.90 Eu 0.10 )MoO 6 , the above-mentioned ferroelectric luminescent film is prepared according to the following steps:

[0036] S1. Weigh 0.9785g acetylacetonate molybdenum C 10 H 14 MoO 6 Dissolved in ethylene glycol, heated to 50°C, stirred for 2 hours, and lowered to room temperature to obtain precursor solution A;

[0037] S2. Weigh 2.7651g bismuth nitrate Bi (NO 3 ) 3 ·5H 2 O, 0.1338g europium nitrate Eu (NO 3 ) 3 ·6H 2 O, dissolved in a mixture of ethylene glycol methyl ether and glacial acetic acid with a volume ratio of 2:1, adding 1.2013g of stabilizer acetylacetone C 5 H 8 O 2 , to obtain the precursor solution B;

[0038] S3. Mix the precursor solutions A and B, stir for 2 hours, and age for 24 hours to obtain the precursor solution C, and adjust the concentration of the solution to 0.10 mol / L;

[0039] S4. ...

Embodiment 2

[0042] This embodiment provides a bismuth molybdate-based transparent ferroelectric light-emitting film, the chemical composition of which is (Bi 1.85 Eu 0.15 )MoO 6 , the above-mentioned ferroelectric luminescent film is prepared according to the following steps:

[0043] S1. Weigh acetylacetonate molybdenum C 10 H 14 MoO 6 : 0.9785g was dissolved in ethylene glycol, heated to 50°C, stirred for 2 hours, and lowered to room temperature to obtain precursor solution A;

[0044] S2. Weigh bismuth nitrate Bi (NO 3 ) 3 ·5H 2 O: 2.6923g, Europium nitrate Eu (NO 3 ) 3 ·6H 2 O: 0.2007g, dissolved in a mixture of ethylene glycol methyl ether and glacial acetic acid with a volume ratio of 2:1, adding stabilizer acetylacetone C 5 H 8 O 2 : 1.2013 g to obtain precursor solution B;

[0045] S3. Mix the precursor solutions A and B, stir for 2 hours, and age for 24 hours to obtain the precursor solution C, and adjust the concentration of the solution to 0.10 mol / L;

[0046] S4. ...

Embodiment 3

[0049] This embodiment provides a bismuth molybdate-based transparent ferroelectric light-emitting film, the chemical composition of which is (Bi 1.80 Eu 0.20 )MoO 6 , the above-mentioned ferroelectric luminescent film is prepared according to the following steps:

[0050] S1. Weigh acetylacetonate molybdenum C 10 H 14 MoO 6 : 0.9785g was dissolved in ethylene glycol, heated to 50°C, stirred for 2 hours, and lowered to room temperature to obtain precursor solution A;

[0051] S2. Weigh bismuth nitrate Bi (NO 3 ) 3 ·5H 2 O: 2.6195g, Europium nitrate Eu (NO 3 ) 3 ·6H 2 O: 0.2676g, dissolved in a mixture of ethylene glycol methyl ether and glacial acetic acid with a volume ratio of 2:1, adding stabilizer acetylacetone C 5 H 8 O 2 : 1.2013 g to obtain precursor solution B;

[0052] S3. Mix the precursor solutions A and B, stir for 2 hours, and age for 24 hours to obtain the precursor solution C, and adjust the concentration of the solution to 0.10 mol / L;

[0053] S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com