Multifunctional bicomponent ceramic tile gum composition and use method thereof

A two-component, composite technology, applied in the field of construction and decoration construction, can solve problems such as shedding, maladaptation, hollowing, etc., and achieve the effect of consistent deformation and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

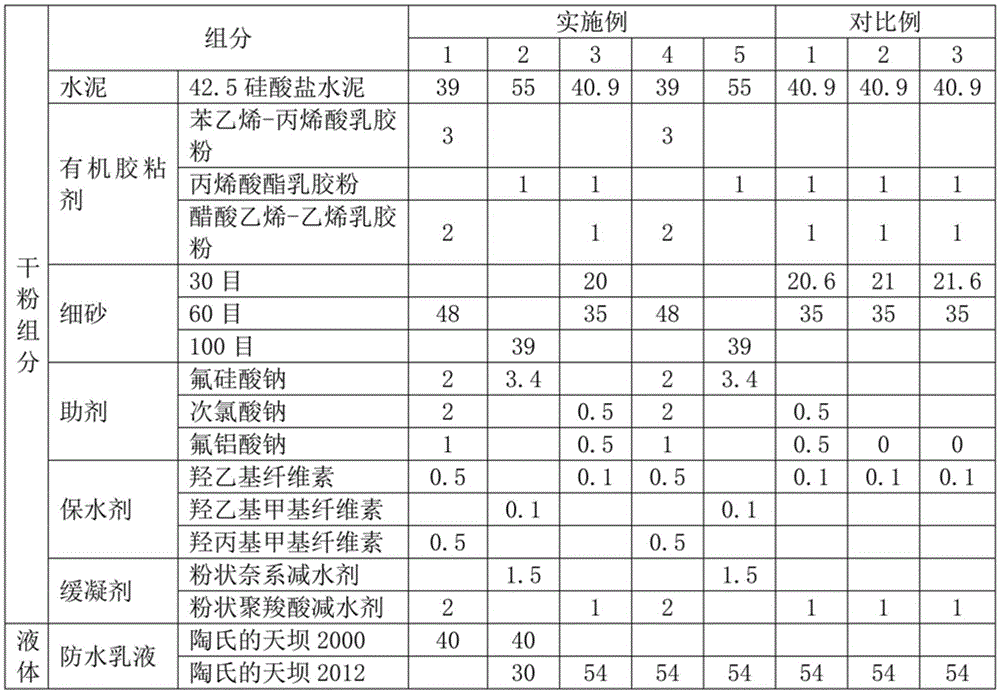

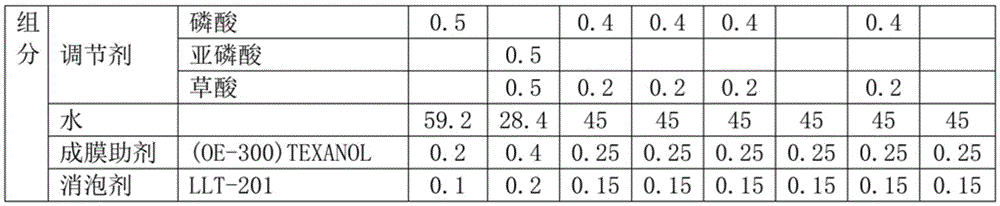

[0035] Embodiments 1 to 5 relate to a multi-functional two-component ceramic tile adhesive composition, the adhesive composition is composed of a dry powder component and a liquid component, and the dry powder is The components and contents included in the components are shown in Table 1 respectively, and the components and contents included in the liquid components are shown in Table 1 respectively in weight percent of the total weight of the liquid components;

[0036] When using, include the following steps:

[0037] S1. Thoroughly stir and mix each component in the dry powder component; obtain a dry powder inorganic material;

[0038] S2. Fully stirring each component in the liquid component to obtain a liquid component material;

[0039] S3. When using, according to the water-cement ratio of 1:3 (water-cement ratio, here refers to the weight ratio of water and dry powder components, you can choose 1:2~5), add water to the dry powder components and stir evenly to make til...

Embodiment 6

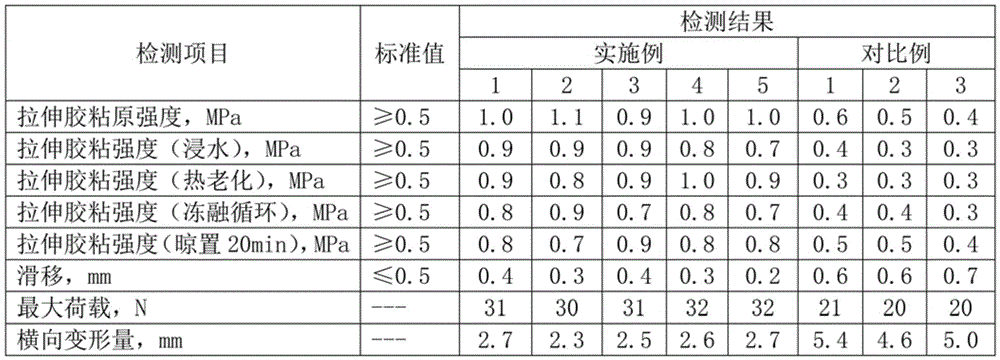

[0049] Embodiment 6, performance test

[0050] Performance tests were performed on the tile adhesives and tile back adhesives prepared in the above-mentioned Examples 1-5 and Comparative Examples 1-3.

[0051] 1) Refer to JC / T547-2005 "Ceramic Wall and Floor Tile Adhesives" testing basis and judgment standards to conduct performance tests on tile adhesives, and the results are shown in Table 2:

[0052] Table 2

[0053]

[0054] 2) Spread the tile adhesive on the wall in batches. After the tile adhesive is dry, apply the corresponding tile adhesive to the back of the tile, and then paste it on the wall. Its corresponding performance is shown in Table 3:

[0055] table 3

[0056]

[0057]

[0058] Cracks appeared in 28 days through comparative examples 1, 2, and 3 samples, and a serious shedding problem occurred after one year, and the tensile bond strength was significantly lower than that of the examples. The samples of Examples 1 to 5 showed no abnormality after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com