A clamping device for a drum brake of a crane hoisting mechanism

A hoisting mechanism and clamping device technology, applied in the direction of hoisting device, transportation and packaging, load hanging components, etc., can solve inconvenient adjustment, it is difficult to ensure that heavy objects will not fall, the brake clamping state is uncontrollable, etc. problem, to achieve the effect of easy adjustment, simple structure, and controllable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

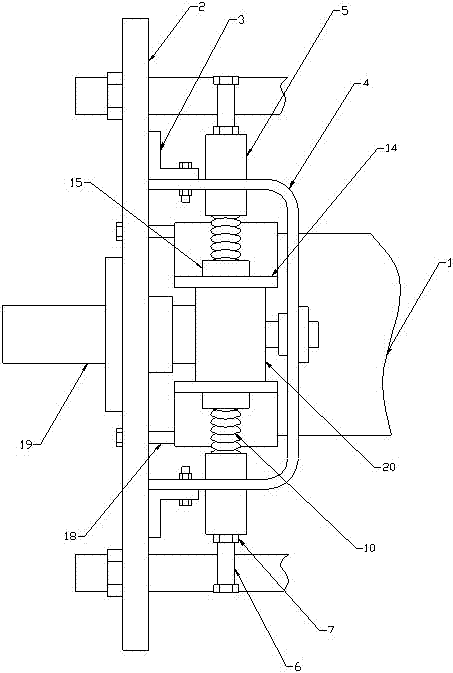

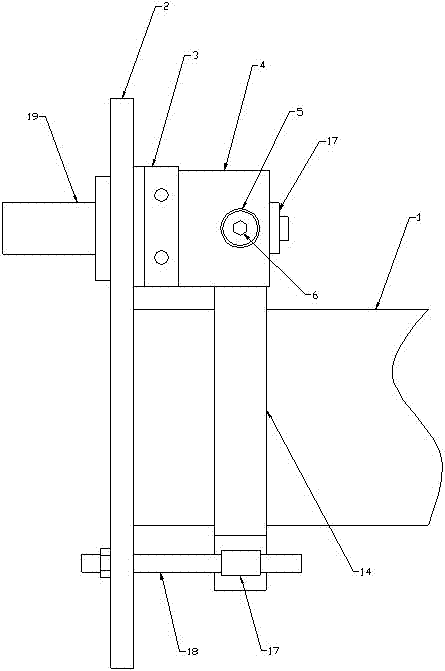

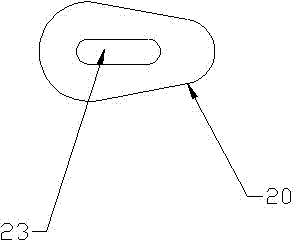

[0026] Such as Figure 1-8 As shown, a clamping device for a roller brake of a crane hoisting mechanism includes a roller 1, one end of the roller 1 is provided with a fixed plate 2, and the upper right side of the fixed plate 2 is provided with a connecting plate 3. The connecting plate 3 is connected with a U-shaped bracket 4 by bolts, the side wall of the U-shaped bracket 4 is embedded with a spring support 5, and one end of the spring support 5 is connected with a thread through a thread Rod 6, the outer wall of the threaded rod 6 is sleeved with a nut 7, the outer surface of the other end of the spring support 5 is provided with a thread, the spring support 5 is connected with an adjusting ring 8 and a fixed ring 9 through the thread, the spring support A spring base 24 and a spring 10 matched with the spring base 24 are sequentially arranged in the seat 5 from inside to outside. The spring base 24 includes a stop ring 11 and a boss 12 connected to the center of one side o...

Embodiment 2

[0029] Such as Figure 1-8 As shown, a clamping device for a roller brake of a crane hoisting mechanism includes a roller 1, one end of the roller 1 is provided with a fixed plate 2, and the upper right side of the fixed plate 2 is provided with a connecting plate 3. The connecting plate 3 is connected with a U-shaped bracket 4 by bolts, the side wall of the U-shaped bracket 4 is embedded with a spring support 5, and one end of the spring support 5 is connected with a thread through a thread Rod 6, the outer wall of the threaded rod 6 is sleeved with a nut 7, the outer surface of the other end of the spring support 5 is provided with a thread, the spring support 5 is connected with an adjusting ring 8 and a fixed ring 9 through the thread, the spring support A spring base 24 and a spring 10 matched with the spring base 24 are sequentially arranged in the seat 5 from inside to outside. The spring base 24 includes a stop ring 11 and a boss 12 connected to the center of one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com