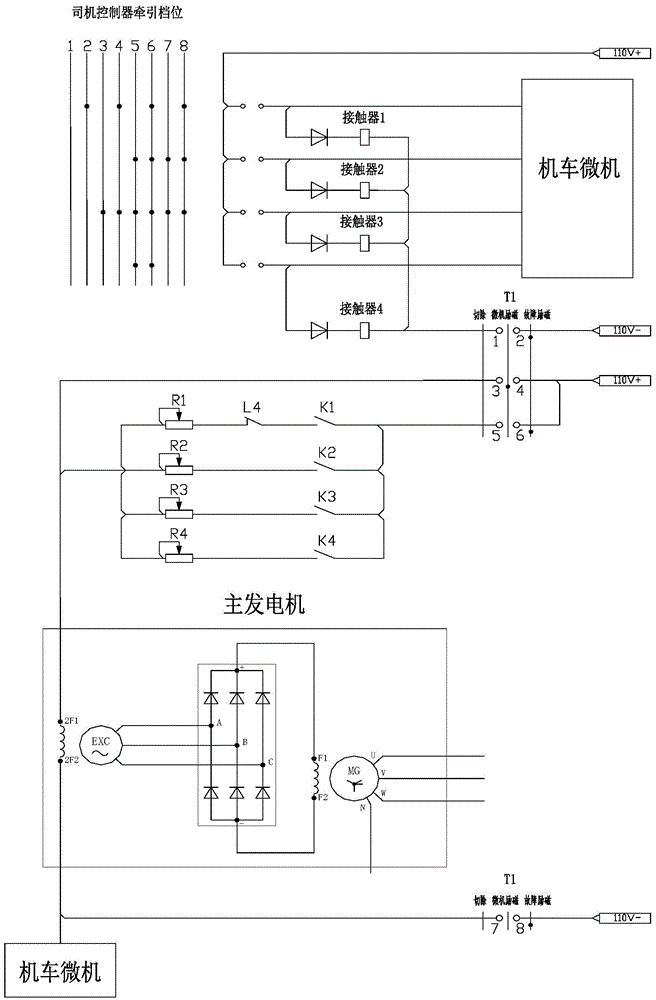

Main generator excitation current variable-level control circuit adopted when locomotive microcomputer excitation control fails

A main generator, excitation control technology, applied in the control drive, control device, electric vehicle and other directions, can solve the problems of low locomotive axle traction power, limited locomotive traction capacity, unable to change the output power of the main generator, etc. The effect of maximizing power and improving towing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] now attached figure 1 To further illustrate the present invention, the main generator of the CKD8G internal combustion locomotive is a brushless excitation generator, and its excitation current, under normal working conditions, is controlled by the power of the diesel engine at different handle speeds set by the locomotive microcomputer. The magnitude of the excitation current is adjusted and controlled. In the fault condition, it is adjusted and controlled by the fault excitation resistor.

[0013] (1) The locomotive microcomputer excitation, the handle of the excitation changeover switch T1 is set to the "microcomputer excitation" position. The locomotive auxiliary power supply 110VDC supplies power to the excitation winding of the brushless excitation main generator, and the locomotive microcomputer controls the average current of the field effect tube to meet the requirements of the locomotive.

[0014] (2) Locomotive fault excitation, the handle of the excitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com