Fast response adhesion strong crossed membrane self-adhering waterproof roll and preparation process thereof

A technology of self-adhesive waterproof membrane and strong cross-membrane, which is applied in lamination, layered products, asphalt layered products, etc. Healing performance, easy maintenance, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

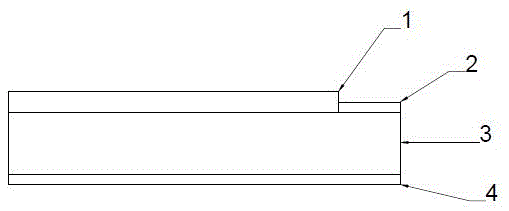

[0031] Such as figure 1 As shown, a self-adhesive waterproof membrane with quick-response sticky strength cross-membrane, the waterproof membrane includes an upper covering layer 1, a reactive wet-laid self-adhesive gel layer 3 and a lower covering layer 4 from top to bottom. The surrounding edge of the above-mentioned upper cladding surface layer is provided with overlapping edge or edge film 2; The described upper cladding surface layer is a strong cross-laminated polyethylene film, and the strong cross-laminated polyethylene film is made of two layers of high-density polyethylene film 45 °Cross-composite hot pressing; the overlapping edge is a silicon-coated isolation film, and the lower surface layer is also made of a silicon-coated isolation film, and the silicon-coated isolation film is coated with polyethylene terephthalate (PET). Silicon isolation film.

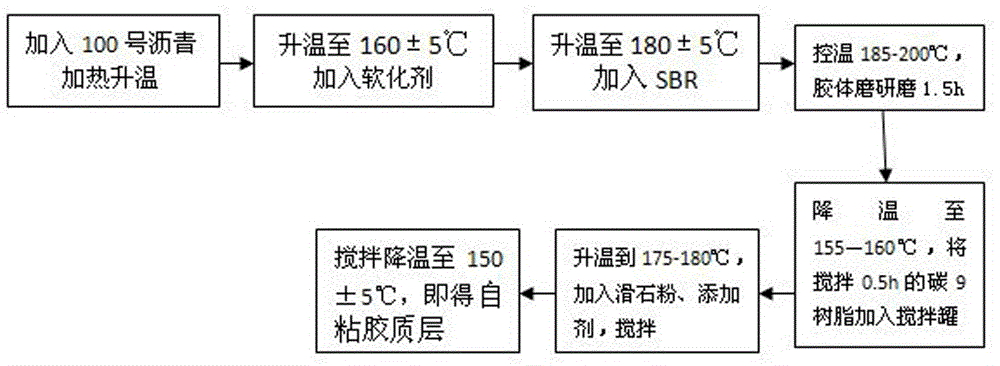

[0032] The reactive wet-laid self-adhesive colloidal layer is made of the following raw materials in parts by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com