Positioning device for clamping of arc-shaped wallboard

A technology of positioning device and wall plate, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high cost and complex device structure, and achieve the effects of low cost, short positioning time and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

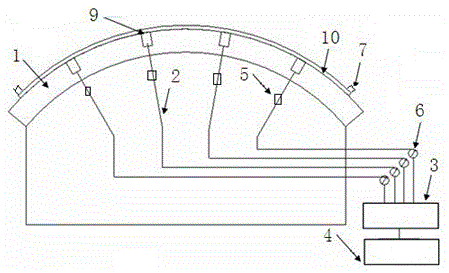

[0020] see figure 1 and 4 , a clamping and positioning device for arc-shaped wall panels, including a vacuum chuck 1 and a negative pressure subsystem, the negative pressure subsystem includes an air compressor 4 and a vacuum generator 3 connected to the air compressor 4, and the vacuum chuck 1 passes through The vacuum air guide tube 2 is connected to the vacuum generator 3, and a pressure sensor 5 is also provided on the vacuum air guide tube 2 near the vacuum chuck 1, and an air circuit switch 6 is also provided on the position of the vacuum air guide tube 2 close to the vacuum generator 3; A pressure plate 7 is also arranged around the vacuum chuck 1;

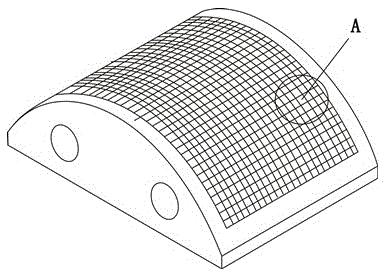

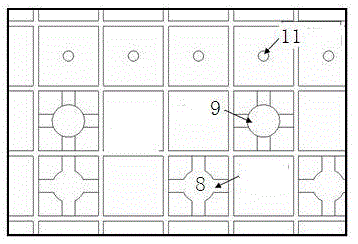

[0021] The main part of the vacuum chuck 1 is a casting mold, and its structure is as follows: figure 2 and 3 As shown, sealing grooves 8 are uniformly arranged on the casting surface, and the spacing of the sealing grooves 8 is 100mm*100mm, and O-shaped sealing strips corresponding to the sealing grooves 8 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com