Manufacturing method for annular rail in drum

A manufacturing method and an inner ring technology are applied in the field of manufacturing the inner ring track of the drum, which can solve the problems of high cost and high equipment processing capacity requirements, and achieve the effect of ensuring the use effect, solving the high processing capacity requirements and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiment of the present application solves the technical problem that the manufacturing method in the prior art has high requirements on the processing capability of the equipment and the high cost by providing a method for manufacturing an annular track in a rotating drum.

[0025] The technical solutions in the embodiments of the present application are to solve the above technical problems, and the general idea is as follows:

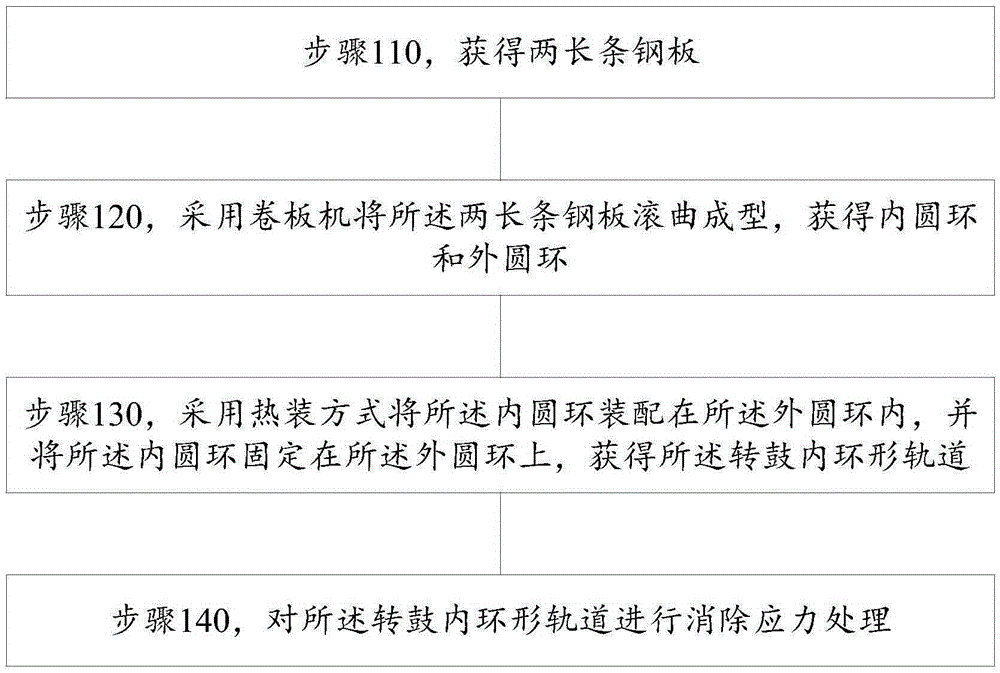

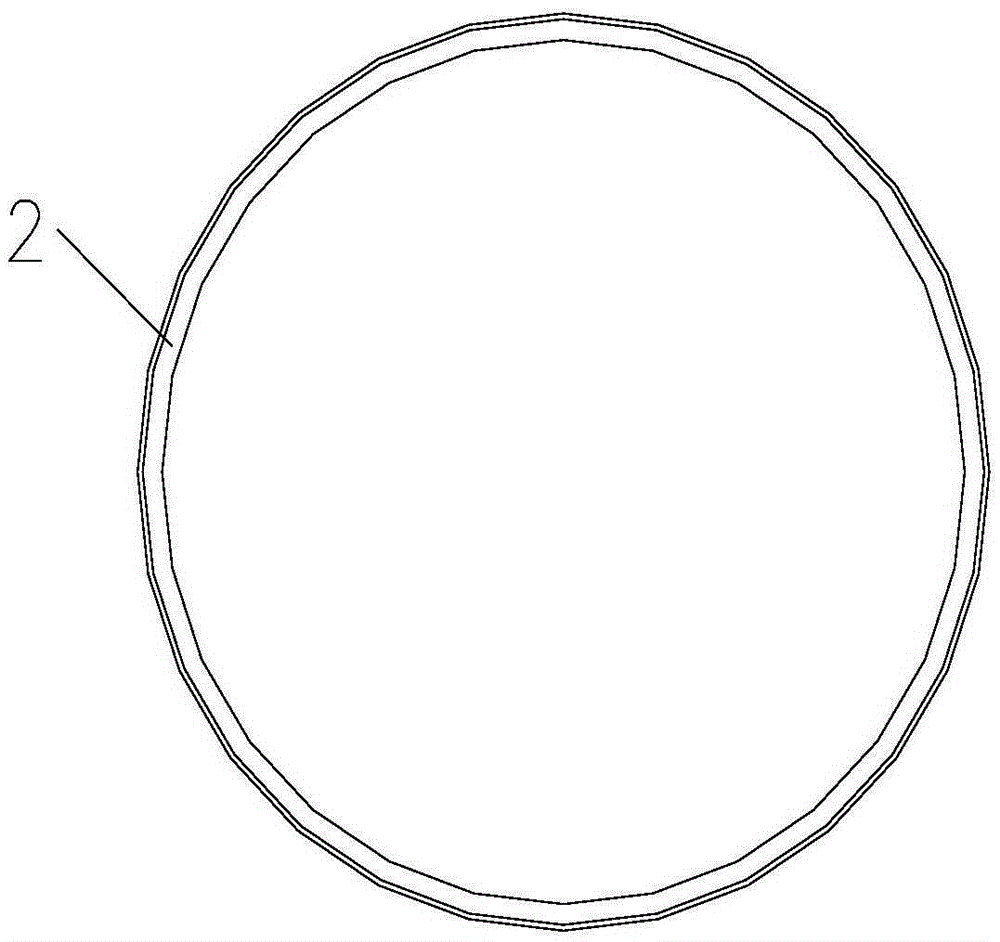

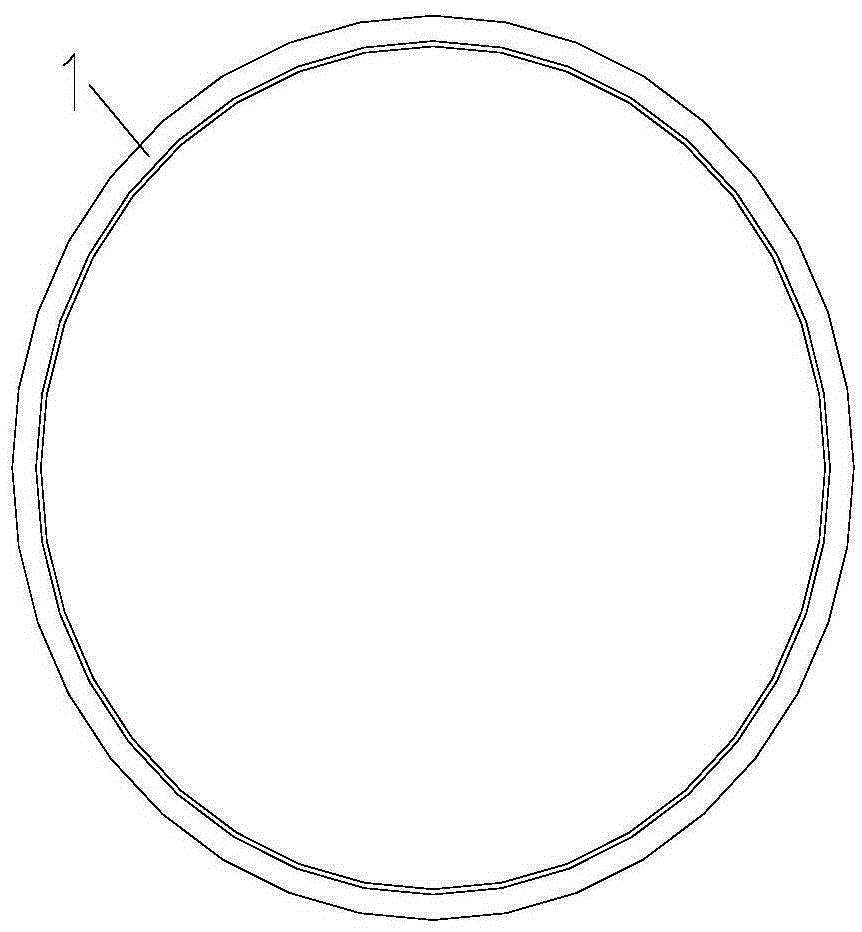

[0026] A method for manufacturing an annular track in a rotating drum, the manufacturing method comprising: obtaining two long steel plates; using a plate bending machine to roll the two long steel plates to obtain an inner ring and an outer ring; Assemble the inner ring in the outer ring, and fix the inner ring on the outer ring to obtain the inner ring track of the drum; Stress relief treatment.

[0027] The manufacturing method of the above-mentioned inner ring track of the rotating drum is made by dividing the inner ring track of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com