Silver nanowire assembly and preparation method and flexible conductor thereof

A technology of silver nanowires and flexible conductors, applied in the field of nanomaterials, can solve the problems of many process steps and general electrical and mechanical properties of silver nanowire assemblies, and achieve the effects of simple process, good cycle characteristics and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a silver nanowire assembly, comprising:

[0032] reacting polyvinylpyrrolidone solution and silver salt solution to obtain silver nanowire assembly;

[0033] The solvent in the polyvinylpyrrolidone solution includes ethylene glycol and glycerol;

[0034] The reaction temperature is from 100°C to 300°C.

[0035] In the invention, polyvinylpyrrolidone solution and silver salt solution are reacted to obtain silver nanowire assembly. In the present invention, the reaction temperature is from 100°C to 300°C. In an embodiment of the present invention, the temperature of the reaction is 120°C to 280°C; in other embodiments, the temperature of the reaction is 140°C to 260°C; in another embodiment, the temperature of the reaction is The temperature is 160°C-240°C; in another embodiment, the temperature of the reaction is 180°C-220°C.

[0036] In the embodiments of the present invention, the time of the reaction is 10 hours to 30 ...

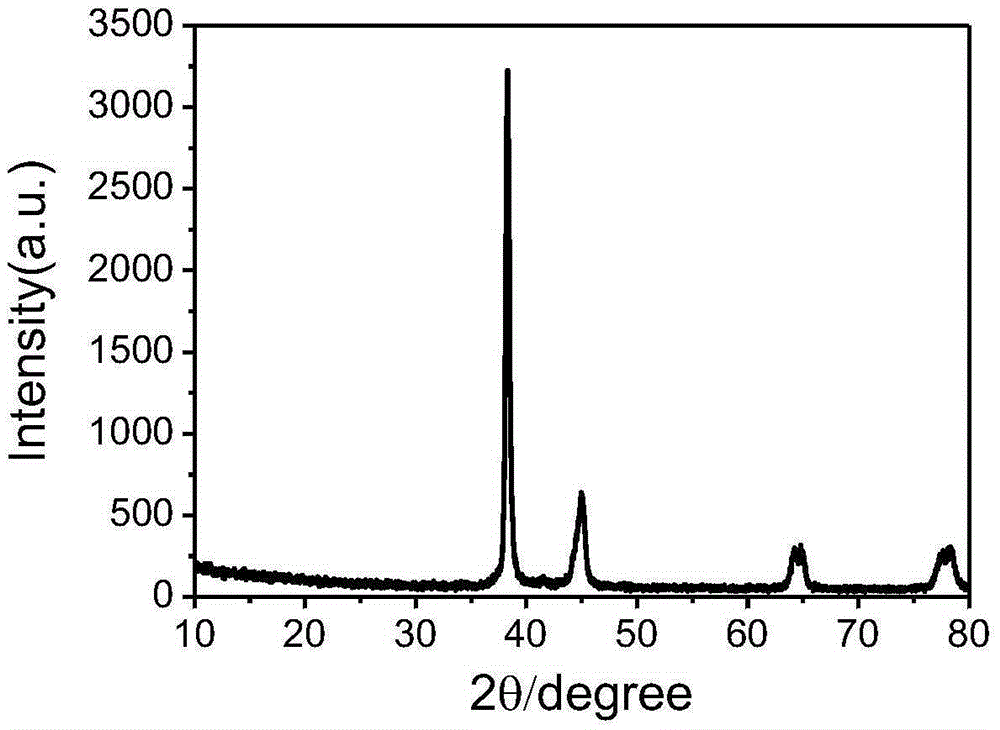

Embodiment 1

[0068] In the case of constant stirring, 1.0 grams of polyvinylpyrrolidone (PVP) with a number-average molecular weight of 55,000 was added to 40 milliliters of a mixed solution of glycerol and ethylene glycol at a mass ratio of 16:1, and the resulting mixture The solution was heated to 125°C in an oil bath and stirred at 500 rpm; after stirring for 0.5 hours, a transparent light yellow solution was obtained; the obtained light yellow solution was placed in an ice bath, and removed when the temperature of the above solution dropped to room temperature ice bath to obtain a polyvinylpyrrolidone solution with a temperature of 35°C.

[0069] 0.5 g of silver nitrate was formulated into a 3 mmol / mL aqueous solution, and 0.03 g of sodium chloride was added thereto to obtain a 3 mmol / mL silver chloride solution.

[0070] Add 1 mL of the above silver chloride solution dropwise to the above polyvinylpyrrolidone solution and mix at 35°C to obtain a homogeneous solution; raise the tempera...

Embodiment 2

[0077] In the case of constant stirring, 10.0 grams of polyvinylpyrrolidone (PVP) with a number-average molecular weight of 55,000 was added to 400 milliliters of a mixed solution of ethylene glycol and glycerol at a mass ratio of 1:16, and the resulting mixed The solution was heated to 125°C in an oil bath and stirred at 500 rpm; after stirring for 1 hour, a transparent light yellow solution was obtained; the obtained light yellow solution was placed in an ice bath, and removed when the temperature of the above solution dropped to room temperature ice bath to obtain a polyvinylpyrrolidone solution with a temperature of 35°C.

[0078] 5 g of silver nitrate was formulated into a 3 mmol / mL aqueous solution, and 0.3 g of sodium chloride was added thereto to obtain a 3 mmol / L silver chloride solution.

[0079] Add 10 mL of the above silver chloride solution dropwise to the above polyvinylpyrrolidone solution and mix at 35°C to obtain a homogeneous solution; raise the temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com