Whitening cosmetic composition

A technology for whitening cosmetics and compositions, which can be applied to cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of skin irritation, poor whitening product effect, allergy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

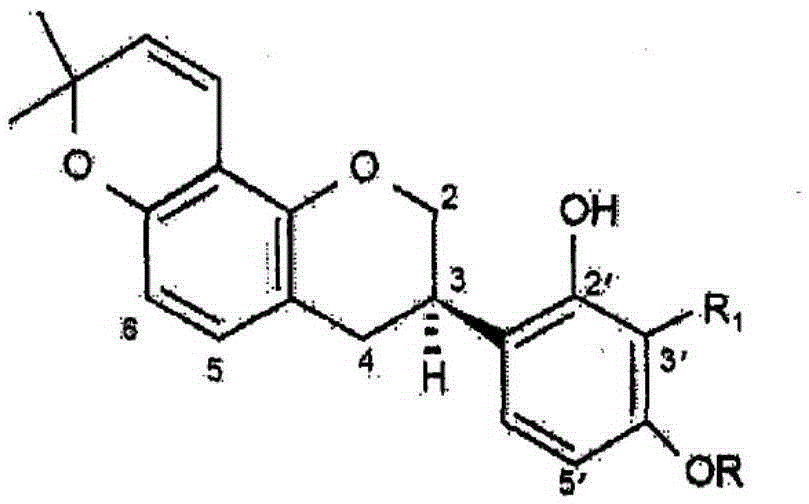

Image

Examples

Embodiment 1-3

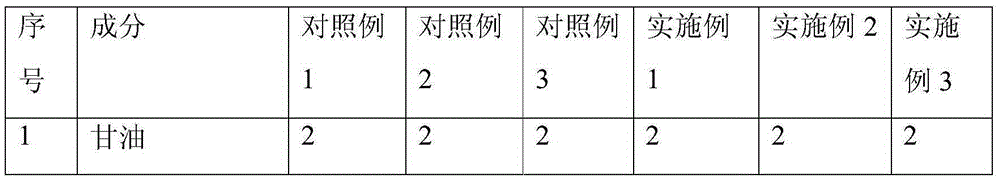

[0047] A whitening cosmetic composition, made into whitening essence water, its raw material composition ratio and the content of the control example raw material composition ratio are shown in Table 1 below.

[0048] The whitening essence water (unit: weight %) of table 1 embodiment 1-3 and comparative example 1-3

[0049]

[0050]

[0051] The manufacturing process of whitening essence water can be expressed as follows:

[0052] Put deionized water into the production pot, add xanthan gum and hyaluronic acid pre-dispersed with glycerin, heat up to 85°C, keep stirring for 20 minutes, turn on the cooling water, cool to 45°C, add 1.3-butanediol Dissolved glabradin-90, whitening compound, citrus peel extract, essence / preservative; stir for 20 minutes, cool to room temperature, and discharge after passing the inspection for later use.

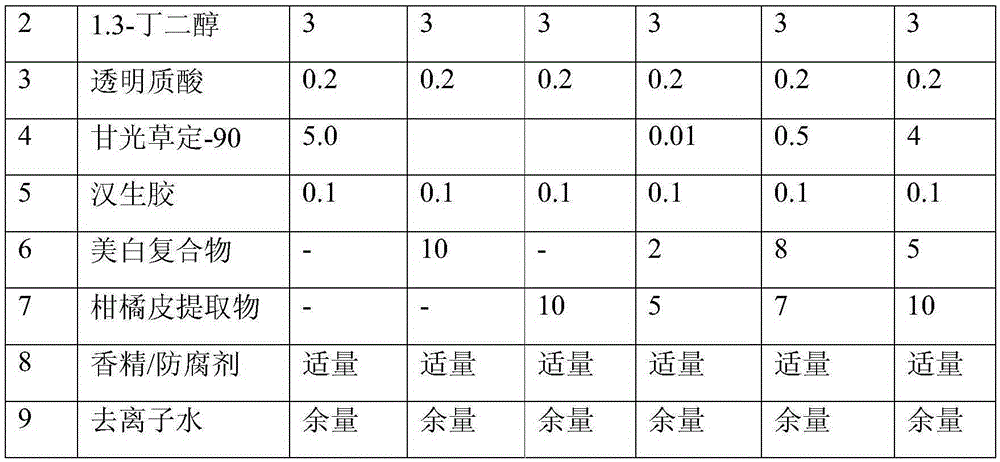

[0053] Ingredient 6-whitening complex, the formula and content of its raw material components are shown in Table 2 below.

[0054] The raw ...

Embodiment 4-6

[0065] A whitening cosmetic composition, made into a whitening emulsion, the proportion of raw material components and the content of the proportion of raw material components in the control example are shown in Table 4 below.

[0066] The whitening emulsion (unit: weight %) of table 4 embodiment 4-6 and comparative example 4-6

[0067]

[0068]

[0069] The manufacturing process of whitening emulsion can be expressed as follows:

[0070] 1) Add deionized water into the water pot, add Carbo 941 under rapid stirring, add glycerin-dispersed hyaluronic acid and xanthan gum after stirring evenly, heat up to 85°C, keep warm and stir for 20 minutes, and set aside;

[0071] 2) Put cetearyl alcohol, cetearyl ether-25, squalane, and jojoba oil into the oil phase pot, heat up to 80°C, keep stirring for 20 minutes, and set aside;

[0072] 3) Pump the water pot and oil pot raw materials into the emulsification pot, homogenize at high speed for 10 minutes, keep stirring for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com