Underwater electromagnetic separation component and underwater electromagnetic separation device

An electromagnetic separation and separation device technology, applied in electrical components, coupling devices, connecting device components and other directions, can solve the problems of high cost, reduce the electromagnetic force of the electromagnetic separation mechanism, prone to separation failure, etc. Gap length, the effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

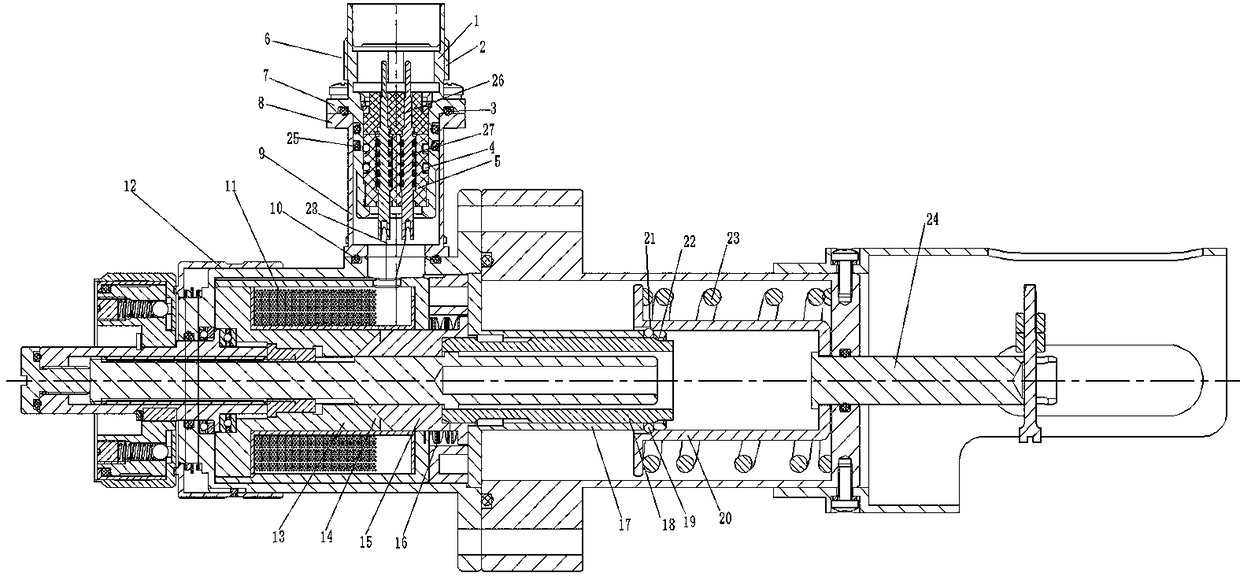

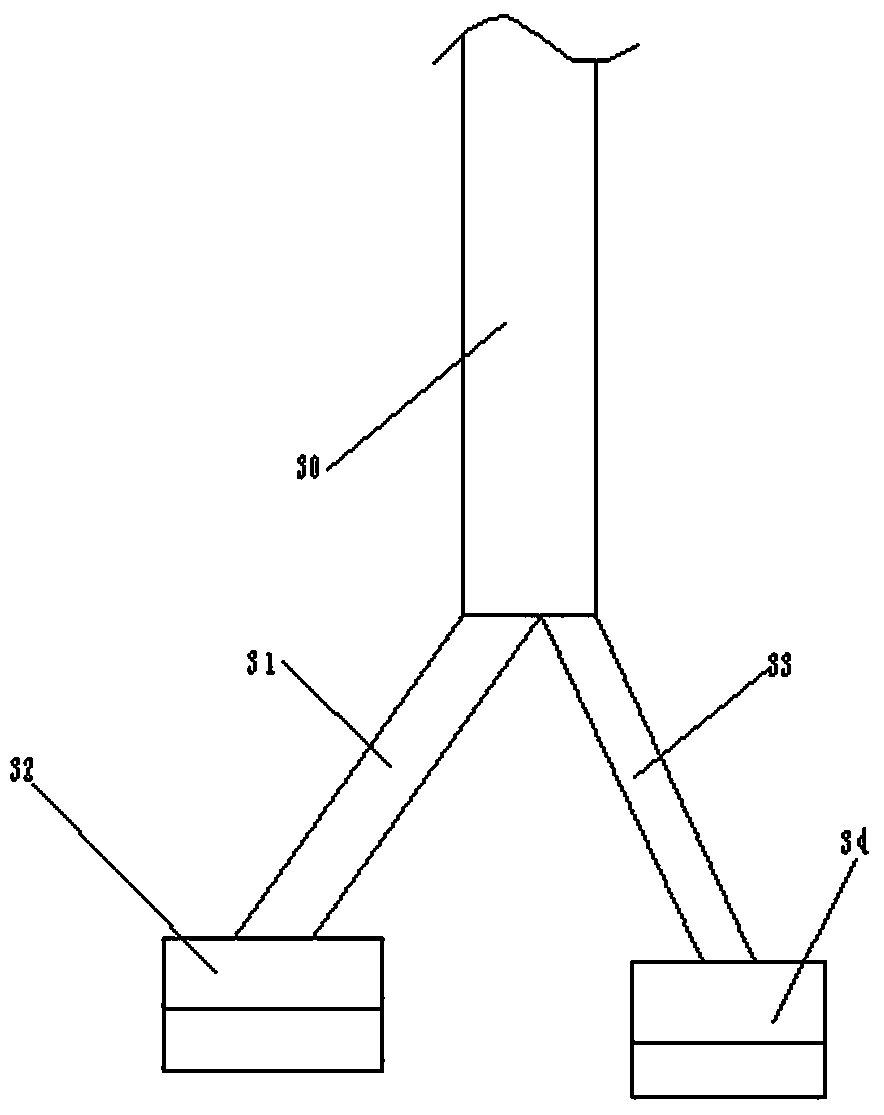

[0023] Examples of underwater electromagnetic separation device components are Figure 1~2 Shown: include power supply cable 31, signal transmission cable 33 and underwater electromagnetic separation device, underwater electromagnetic separation device includes the separation device shell 12 that is provided with electromagnetic separation mechanism inside, for the main part of cable 31, signal transmission cable 33 wears Set in the same cable sheath 30, the end of the power supply cable 31 is provided with a power supply plug 32, and the end of the signal transmission cable 33 is provided with a signal plug 34, that is to say, the power supply cable and the signal transmission cable belong to the same hybrid cable. When stripping the cable sheath end of the hybrid cable, the power supply cable and the signal transmission cable are separated. The electromagnetic separation mechanism includes an electromagnetic coil 11, a fixed iron core 13 and a moving iron core 15 that can gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com