Gradient piezoelectric fiber composite material and preparation method thereof

A fiber composite material and piezoelectric fiber technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of difficulty in maintaining the main structure vibration or Stable and continuous deformation control, distortion point or area of the main structure, increasing the complexity of the drive power system, etc., to achieve the effects of easy operation and use, stable product performance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

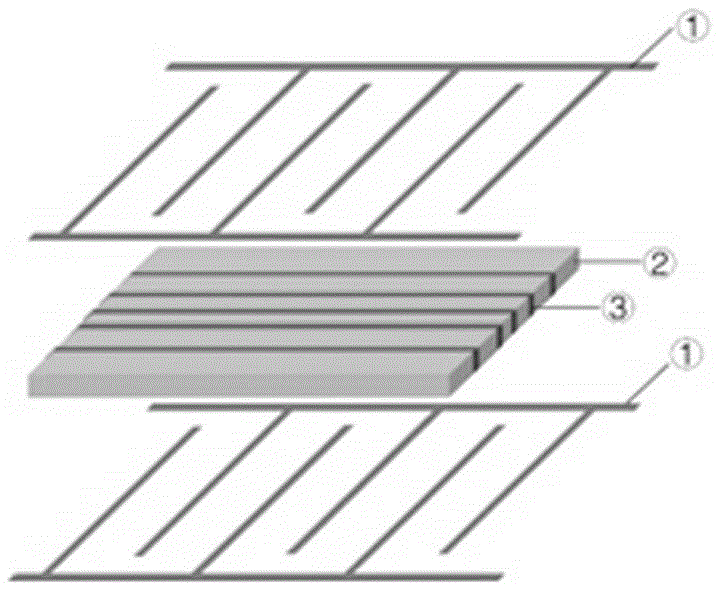

[0030] A gradient piezoelectric fiber composite material, which is composed of two interdigitated electrodes, piezoelectric fibers and polymers, the piezoelectric fibers and polymers are located between the upper and lower interdigitated electrodes, and the interdigitated The positive and negative fingers of the electrode are arranged alternately and equally spaced, and the upper and lower interdigitated electrodes are mirror-symmetrical. The total volume percentage of the piezoelectric fiber and the polymer is 80.6% of the piezoelectric fiber. , high molecular polymer 19.4%, piezoelectric fibers and high molecular polymers are arranged alternately, the volume fraction of a single piezoelectric fiber changes continuously along the transverse direction of the gradient piezoelectric fiber composite material, and along the transverse direction of the piezoelectric fiber composite material direction, the width of a single piezoelectric fiber gradually decreases, showing that the vo...

Embodiment 2

[0037] A gradient piezoelectric fiber composite material, which is composed of two interdigitated electrodes, piezoelectric fibers and polymers, the piezoelectric fibers and polymers are located between the upper and lower interdigitated electrodes, and the interdigitated The positive and negative fingers of the electrode are arranged alternately and equidistantly, and the upper and lower interdigitated electrodes are mirror-symmetrical. The total volume percentage of the piezoelectric fiber and the polymer is 72.5% of the piezoelectric fiber. , high molecular polymer 27.5%, piezoelectric fibers and high molecular polymers are arranged alternately, the volume fraction of a single piezoelectric fiber changes continuously along the transverse direction of the gradient piezoelectric fiber composite material, and along the transverse direction of the piezoelectric fiber composite material direction, the width of a single piezoelectric fiber first increases and then decreases, showi...

Embodiment 3

[0044] A gradient piezoelectric fiber composite material, which is composed of two interdigitated electrodes, piezoelectric fibers and polymers, the piezoelectric fibers and polymers are located between the upper and lower interdigitated electrodes, and the interdigitated The positive and negative fingers of the electrode are arranged alternately and equidistantly, and the upper and lower interdigitated electrodes are mirror-symmetrical. The total volume percentage of the piezoelectric fiber and the polymer is 67.3% of the piezoelectric fiber. , high molecular polymer 32.7%, piezoelectric fibers and high molecular polymers are arranged alternately, the volume fraction of a single piezoelectric fiber changes continuously along the transverse direction of the gradient piezoelectric fiber composite material, and along the transverse direction of the piezoelectric fiber composite material direction, the width of a single piezoelectric fiber first decreases and then increases, showi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com