Local contact back passivated solar cells

A solar cell and partial contact technology, applied in the field of solar cells, can solve the problems of reduced passivation area, reduced cell efficiency, increased contact resistance, etc., to achieve the effects of increased short-circuit current, improved photoelectric conversion efficiency, and reduced series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

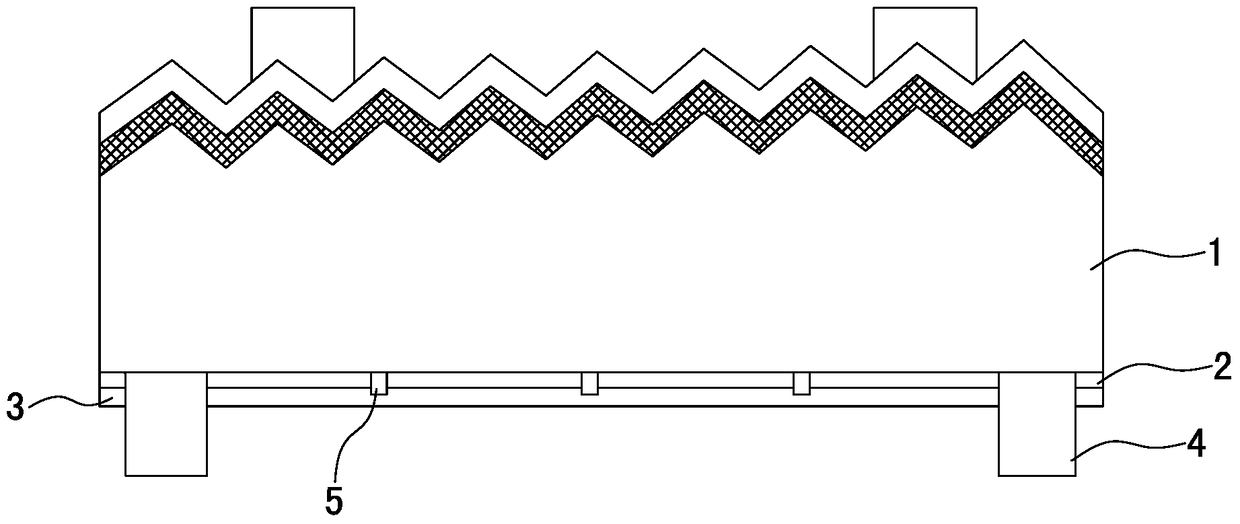

[0034] see Figure 1~3 As shown, a partial contact back passivation solar cell comprises a silicon substrate layer 1, a back passivation film 2 located on the bottom surface of the silicon substrate layer, a back metal layer 3 covering the bottom surface of the back passivation film, and a back passivation film penetrating through the back surface and a plurality of back silver electrodes 4 in the back metal layer and in contact with the bottom surface of the silicon substrate layer, and a plurality of contact regions 5 penetrating through the back passivation film;

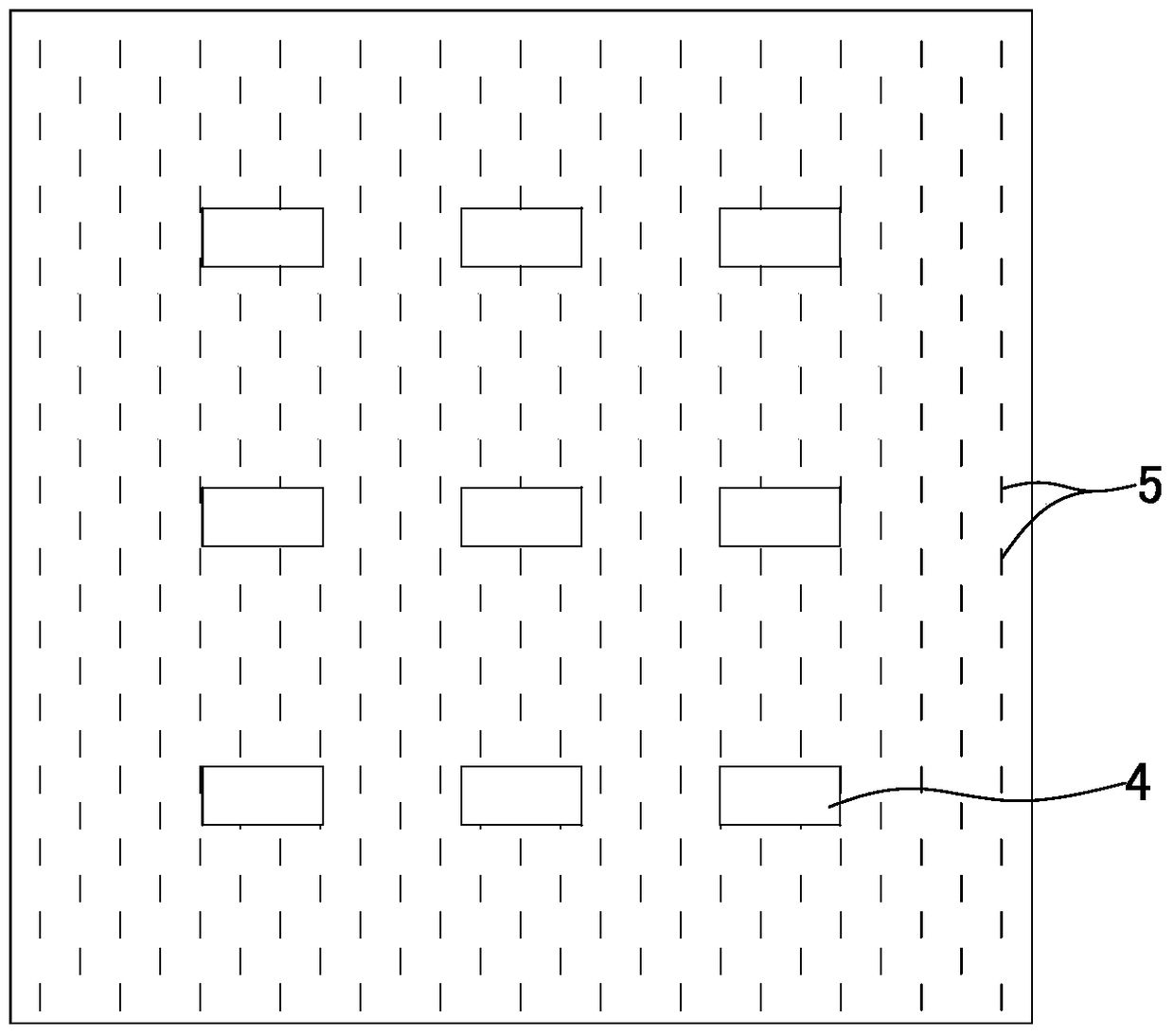

[0035] The upper surface of the contact area is in contact with the bottom surface of the silicon substrate layer, the contact area is in the shape of a line segment and arranged in multiple rows parallel to each other, the contact areas in each row are parallel to each other and distributed at intervals, and the contact areas in adjacent rows are staggered distributed;

[0036] In each row of contact areas, the...

Embodiment 2

[0043] see Figure 4 As shown, a kind of partial contact back passivation solar cell, its structure is similar to embodiment one, the difference is:

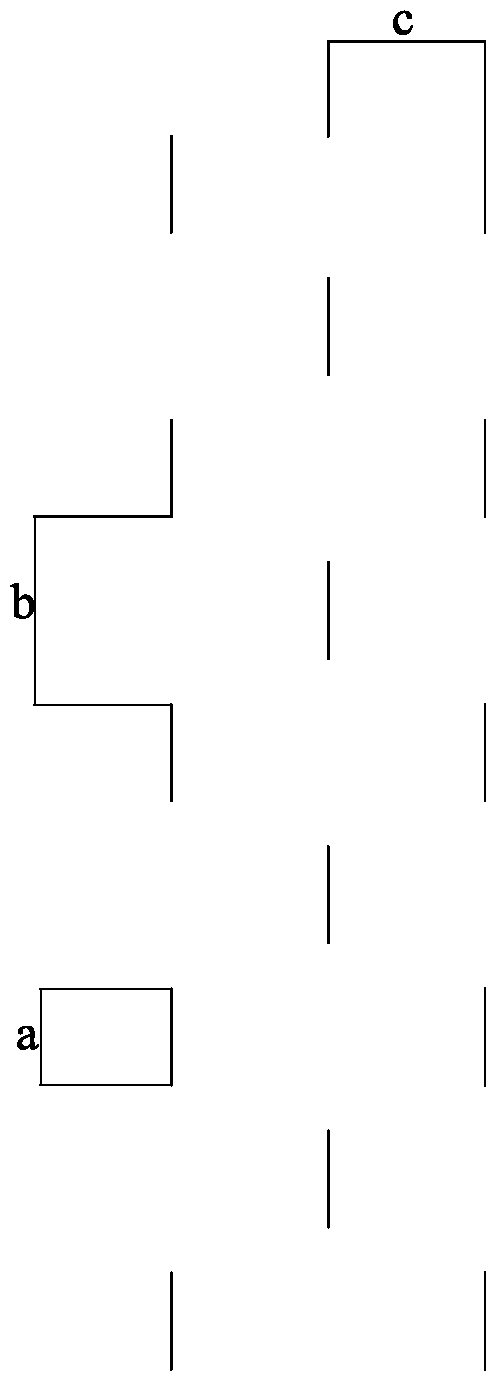

[0044] In each row of contact areas, the length of each contact area is a, and the distance between adjacent contact areas is b; and a is 0.6 mm; b=a, 0.6 mm;

[0045] The spacing c between two adjacent rows of contact areas is 0.8 mm; the spacing between adjacent two rows of contact areas is the same;

[0046] The total area of the contact area accounts for 2.5% of the area of the backside of the silicon wafer.

[0047] In the above technical solution, the width of the contact area is 30 microns.

[0048] The extension direction of the contact area is the same as the extension direction of the back silver electrode.

[0049] The back metal layer is an aluminum layer, and the contact area is a silicon aluminum alloy contact area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com