Aluminum electrolytic production technology optimization method based on BP neural network and MBFO algorithm

A BP neural network and production process technology, applied in the field of aluminum electrolysis industry, can solve the problems of difficult real-time measurement and adjustment of parameters, many parameters in the tank, difficulty in control optimization, etc., to reduce energy consumption per ton of aluminum and perfluorinated emissions Quantity, improved current efficiency, and strong non-linear mapping capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

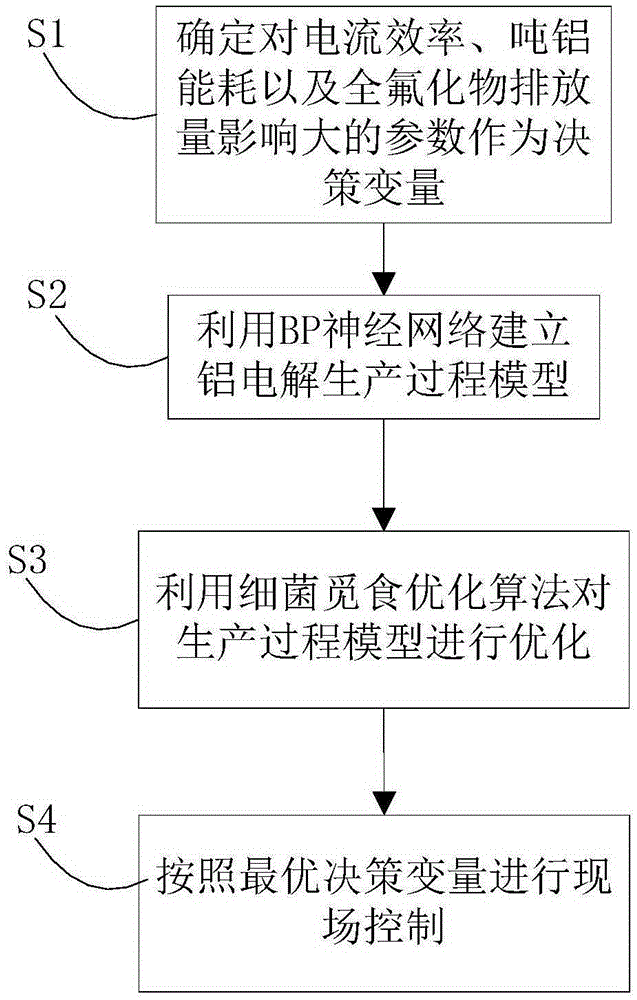

[0037] from figure 1 It can be seen that an aluminum electrolysis production process optimization method based on BP neural network and MBFO algorithm includes the following steps:

[0038] S1: Select control parameters that affect current efficiency, energy consumption per ton of aluminum, and perfluorinated compound emissions to form a decision variable X=[x 1 ,x 2 ,...,x M ], M is the number of selected parameters;

[0039] In the implementation process, the original variables that have an impact on current efficiency, energy consumption per ton of aluminum, and perfluoride emissions in the production process of aluminum electrolysis are counted, and the impact on current efficiency, energy consumption per ton of aluminum in the production process of aluminum electrolysis is determined from them. Consumption and perfluorinated compounds emissions have the greatest impact as the decision variable X;

[0040]Through the statistics of the measured parameters in the actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com