Hollow-solid composite multi-core photonic crystal fiber and its laser amplification method

A photonic crystal fiber, solid technology, applied in the direction of laser, cladding fiber, optical waveguide light guide, etc., can solve the problem that the signal laser is difficult to gain and amplify, the laser pulse energy cannot be amplified, and the laser mode field and the doped medium cannot effectively overlap, etc. problem, to achieve the effect of excellent beam quality and improved withstand power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

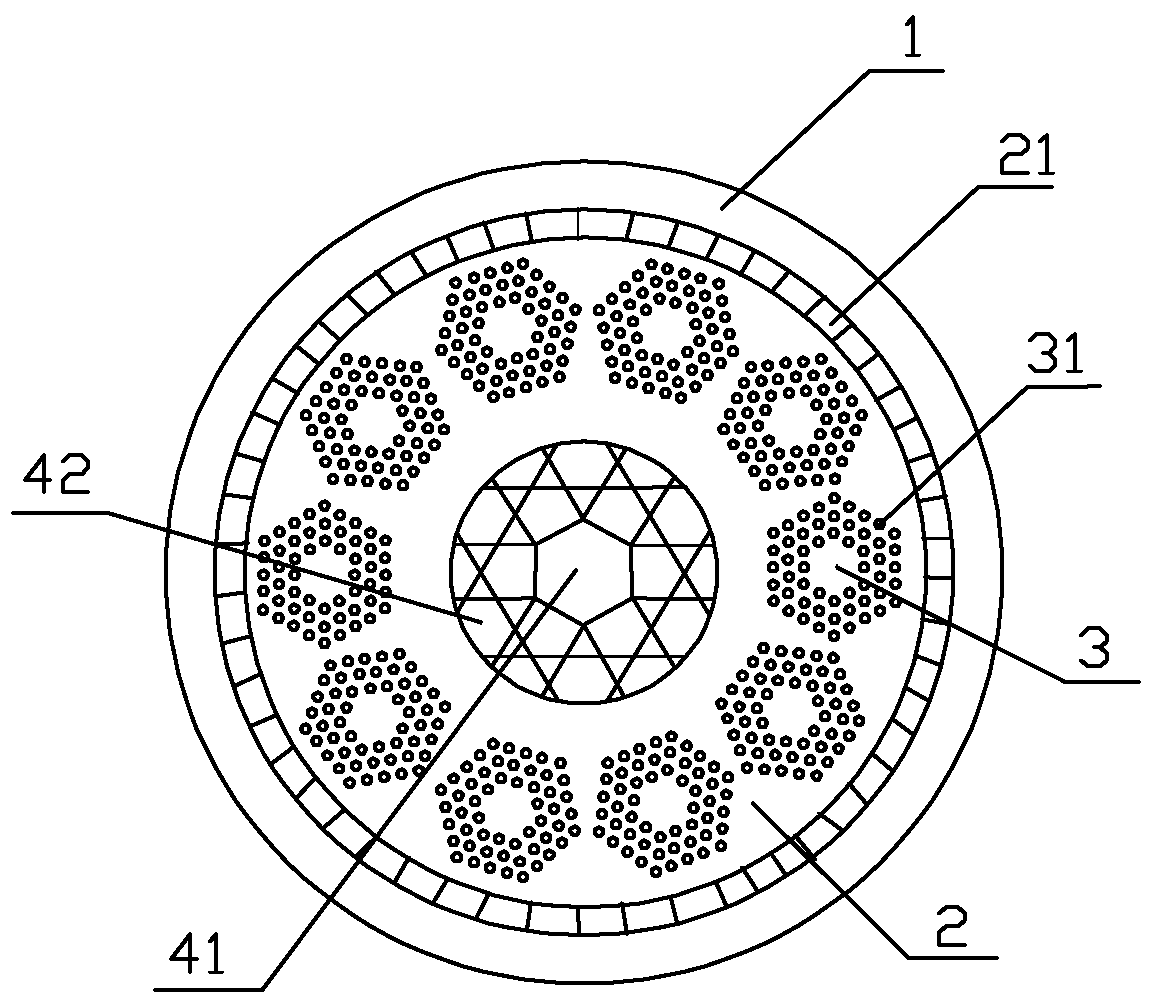

[0026] Such as figure 1 As shown, a hollow-solid composite multi-core photonic crystal fiber comprises from outside to inside: protective layer 1, cladding 2, solid gain core 3 and hollow core 41, cladding 2 around the hollow core 41 Micro-air holes 42 are formed, and the cladding 2 with the micro-air holes 42 and the hollow core 41 form the same structure as the hollow photonic crystal fiber. The hollow core 41 is used to transmit high-energy signal laser light, and the micro-air holes 42 are used to limit the signal laser light. In the hollow core 41 , in this embodiment, preferably, the hollow core photonic crystal fiber is a kagomé structured fiber, and the inside of the hollow core 41 is in a vacuum state, which can further increase the withstand power and damage threshold of the hollow core 41 . The cladding 2 around the solid gain core 3 is provided with regularly arranged micro-holes 31, and the cladding 2 with the micro-holes 31 and the solid gain core 3 form the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com