Machine vision-based online detection device of sizes of small-type and mini-type shaft parts

A technology of machine vision and detection devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of fixed and single, and achieve the effects of good integrity, promotion of improvement, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are given below in conjunction with the accompanying drawings, and the technical solutions of the present invention are described in detail.

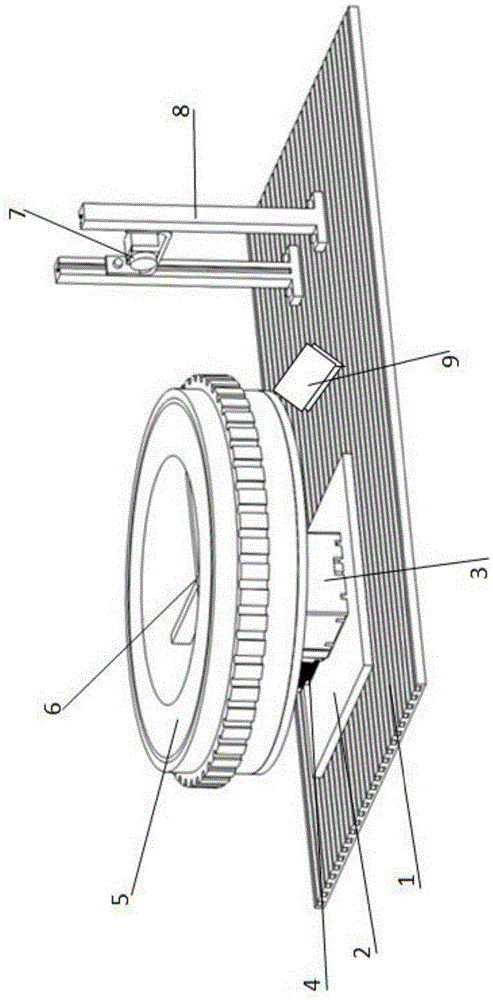

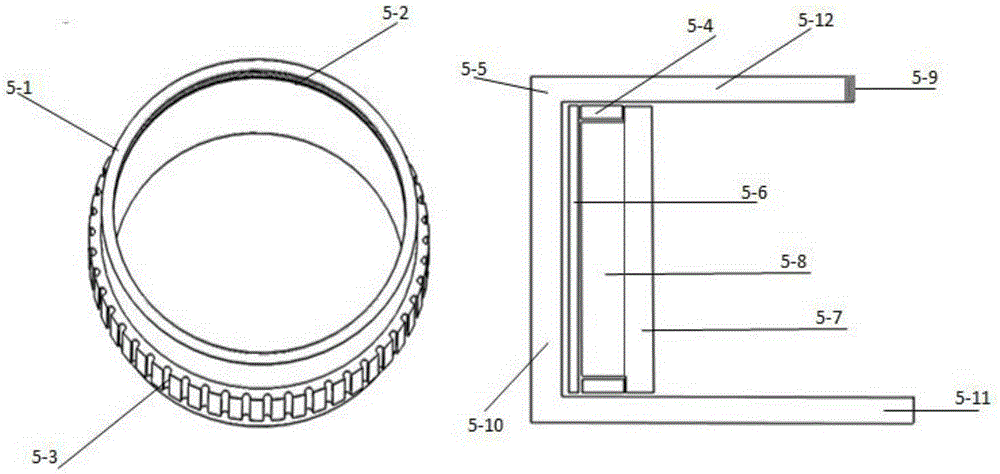

[0017] Such as figure 1 As shown, a small and miniature shaft component size online detection device based on machine vision is characterized in that the device includes a base 1 and a movable camera bracket 8, a motor 3 and a reducer 4 assembly mounted on the base, and a bearing 6 It is composed of the rotating light source detection disk 5 connected with the coupling 6 and the reducer, and the control part with the single-chip microcomputer as the core.

[0018] The said base 1 cooperates with the camera bracket, and is used to fix the whole device. figure 2 As shown, the horizontal and vertical distances of the image acquisition device relative to the measured object are adjusted through the slideway and corresponding connecting parts, so as to obtain the best real-time image data of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com