An encircling one-way device

A one-way device and ring body technology, applied in the field of embracing one-way devices, can solve the problems of non-shifting, skipping, unreliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

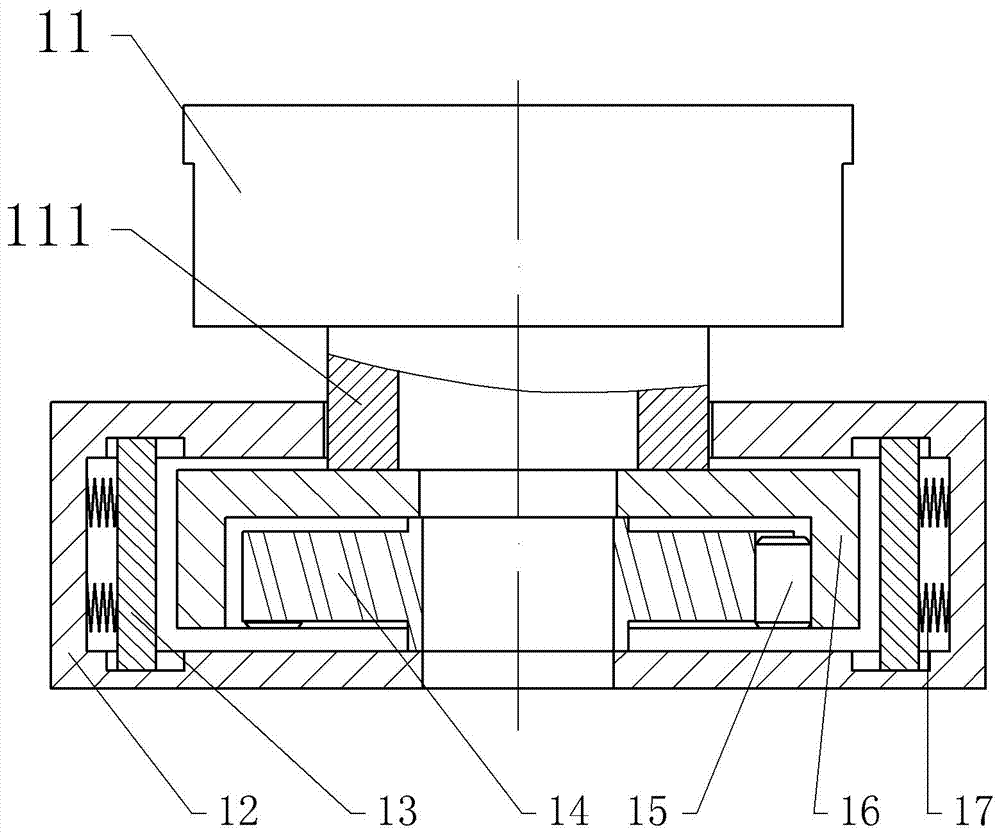

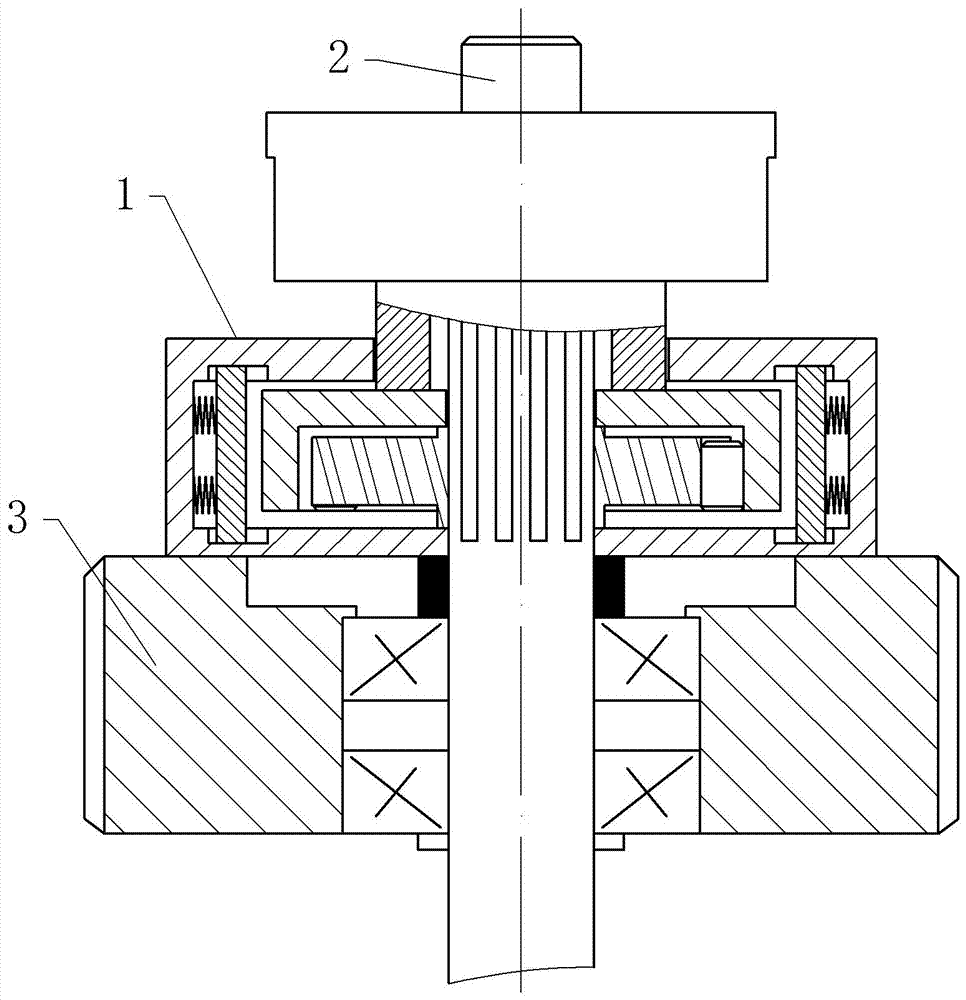

[0015] The reference signs in the accompanying drawings of the specification include: encircling one-way device 1, output shaft 2, low-speed gear 3, solenoid valve 11, housing 12, friction plate 13, cam 14, roller 15, ring body 16, spring 17 , Iron core 111.

[0016] The embodiment is basically as attached figure 1 As shown: the encircling one-way device 1 includes a housing 12, a solenoid valve 11, a friction plate 13, a ring body 16, a cam 14 and a roller 15; wherein the friction plate 13 is tile-shaped, and the friction plate 13 is evenly inlaid There are iron blocks, so that it can be attracted by magnets; there are four friction plates 13, and a chute is provided on the housing 12, and the two ends of the friction plates 13 are inserted into the chute on the housing 12, so that the friction plates 13 are all aligned with the The housing 12 is slidably connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com