A method of inducing the self-assembly of titanium dioxide nanoparticles to form a pearl chain structure

A nanoparticle, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of easy breakdown and destruction of devices, limiting the use range of nanoparticles and solvents, and high electric field strength, etc., to expand the use range, The effect of shortening the self-assembly time and reducing the electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

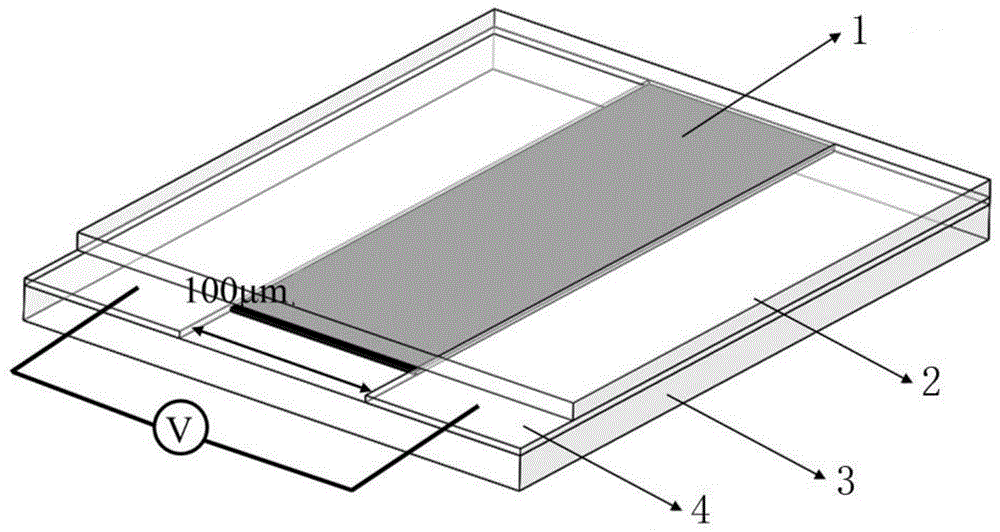

Embodiment 1

[0027] 1 Modification of titanium dioxide:

[0028] Disperse 0.2g of titanium dioxide nanoparticles in 0.3g of styrene and 0.015g of divinylbenzene and sonicate for 20min, then pour into a methanol solution of 2w / v% polyvinylpyrrolidone and sonicate for 20min, pour it into a three-necked flask after dispersion, and Under the protection of nitrogen, 0.01g of azobisisobutyronitrile was added to it, the stirring speed was 350r / min, after the temperature was raised to 65°C, nitrogen was blown and the reaction was stirred for 6h;

[0029] Then slowly add 0.03g of methyl methacrylate into the flask, maintain the stirring speed, and finish the reaction at 65°C for 12 hours. The reaction mixture is repeatedly washed with deionized and ethanol three times, and after vacuum drying, a white solid powder is obtained, which is the modified Titanium dioxide nanoparticles;

[0030]

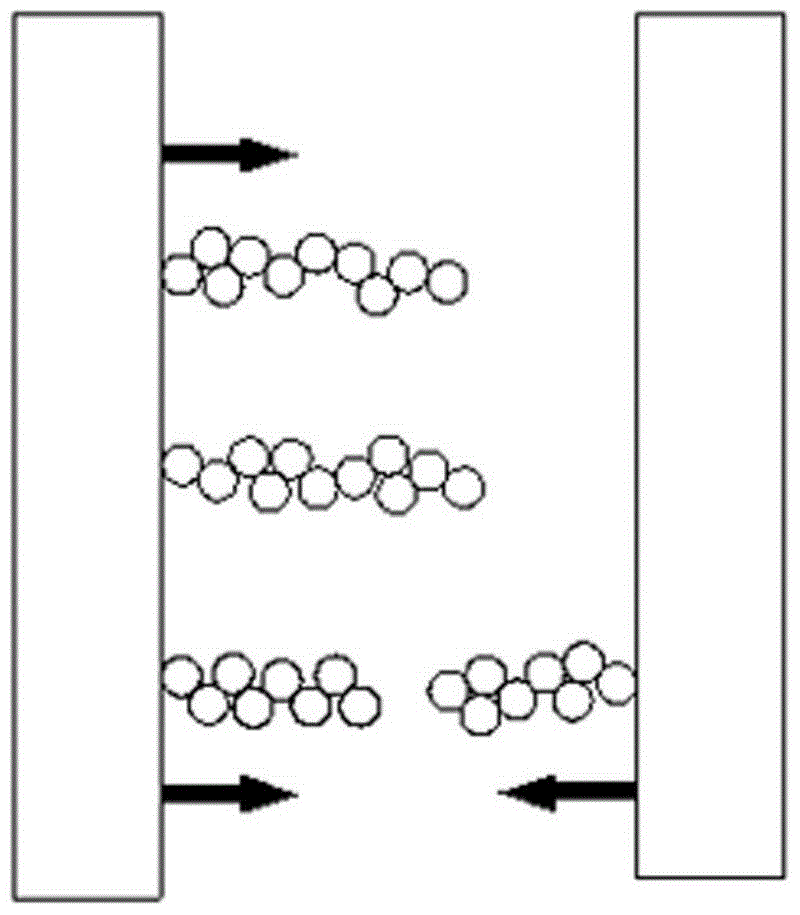

[0031] Unmodified titanium dioxide particles adsorb cations, the colloidal particles are positively charg...

Embodiment 2

[0036] 1 Modification of titanium dioxide:

[0037] Disperse 0.5g of titanium dioxide nanoparticles in 0.5g of styrene and 0.04g of divinylbenzene and sonicate for 30min, then pour it into a methanol solution of 3w / v% polyvinylpyrrolidone and sonicate for 30min, pour it into a three-necked flask after dispersion, and Under the protection of nitrogen, 0.02g of azobisisobutyronitrile was added to it, the stirring speed was 500r / min, after the temperature was raised to 60°C, nitrogen was blown and the reaction was stirred for 8h;

[0038] Then slowly add 0.05g of methyl methacrylate into the flask, maintain the stirring speed, and finish the reaction at 60°C for 15 hours. The reaction mixture is repeatedly washed with deionized and ethanol three times, and after vacuum drying, a white solid powder is obtained, which is the modified Titanium dioxide nanoparticles;

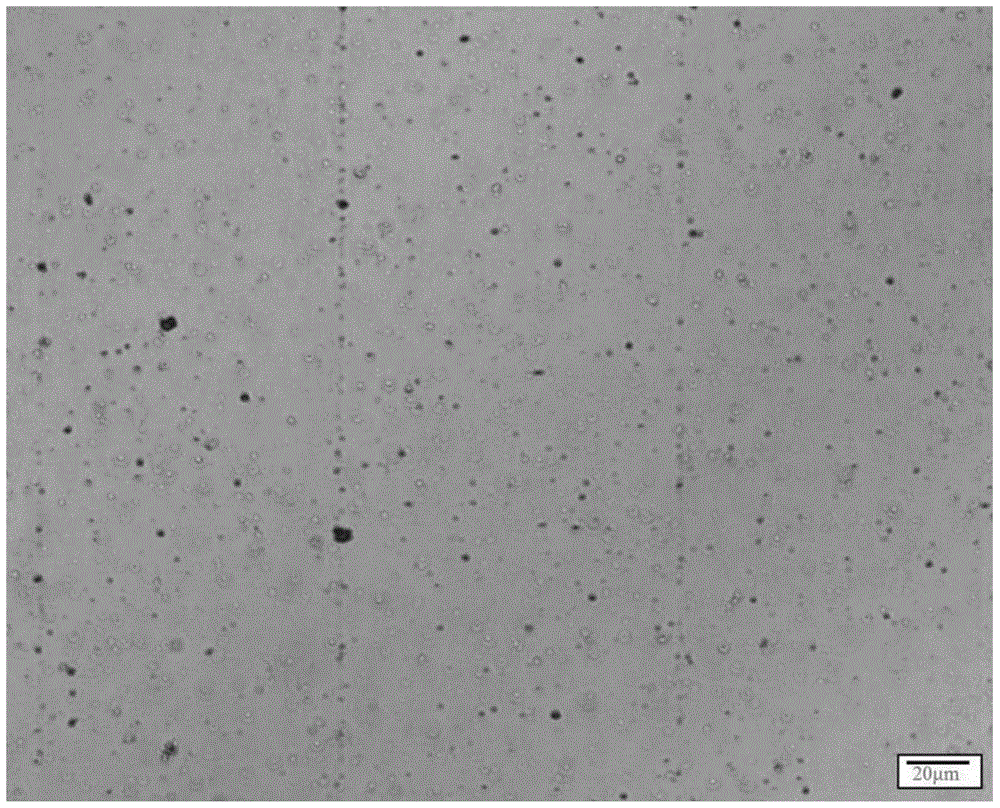

[0039] 2 Self-assembled structures:

[0040]Disperse 0.01g of modified titanium dioxide nanoparticles in 15mL of n...

Embodiment 3

[0042] 1 Modification of titanium dioxide:

[0043] Disperse 0.2g of titanium dioxide nanoparticles in 0.4g of styrene and 0.03g of divinylbenzene and sonicate for 15min, then pour into a methanol solution of 4w / v% polyvinylpyrrolidone and sonicate for 15min, and pour it into a three-necked flask after dispersion. Under the protection of nitrogen, 0.01g of azobisisobutyronitrile was added to it, the stirring speed was 400r / min, after the temperature was raised to 70°C, nitrogen was blown and the reaction was stirred for 5h;

[0044] Then slowly add 0.04g of methyl methacrylate into the flask, maintain the stirring speed, and finish the reaction at 70°C for 10 hours. The reaction mixture is repeatedly washed with deionized and ethanol three times, and after vacuum drying, a white solid powder is obtained, which is the modified Titanium dioxide nanoparticles;

[0045] 2 Self-assembled structures:

[0046] Disperse 0.005g of modified titanium dioxide nanoparticles in 10mL of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com