A new CNC silicon steel sheet cutting line equipment

A silicon steel sheet and cross-cutting line technology, applied in the field of new CNC silicon steel sheet cross-cutting line equipment, can solve the problems of wasting materials, prone to distortion, bulging, and affecting efficiency, so as to reduce worker operations, reduce sheet waste, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

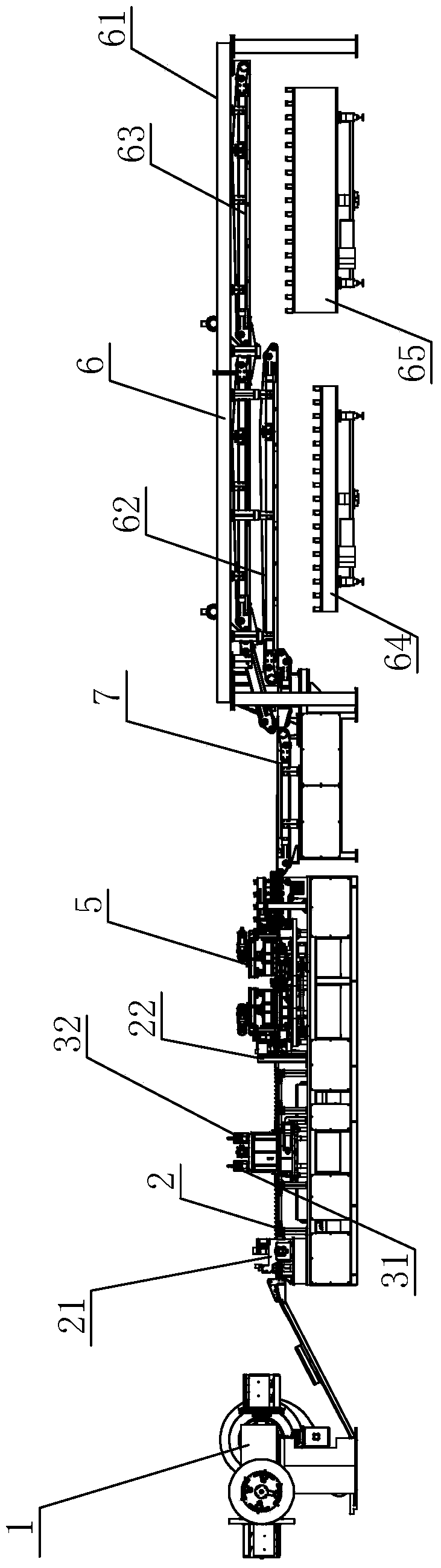

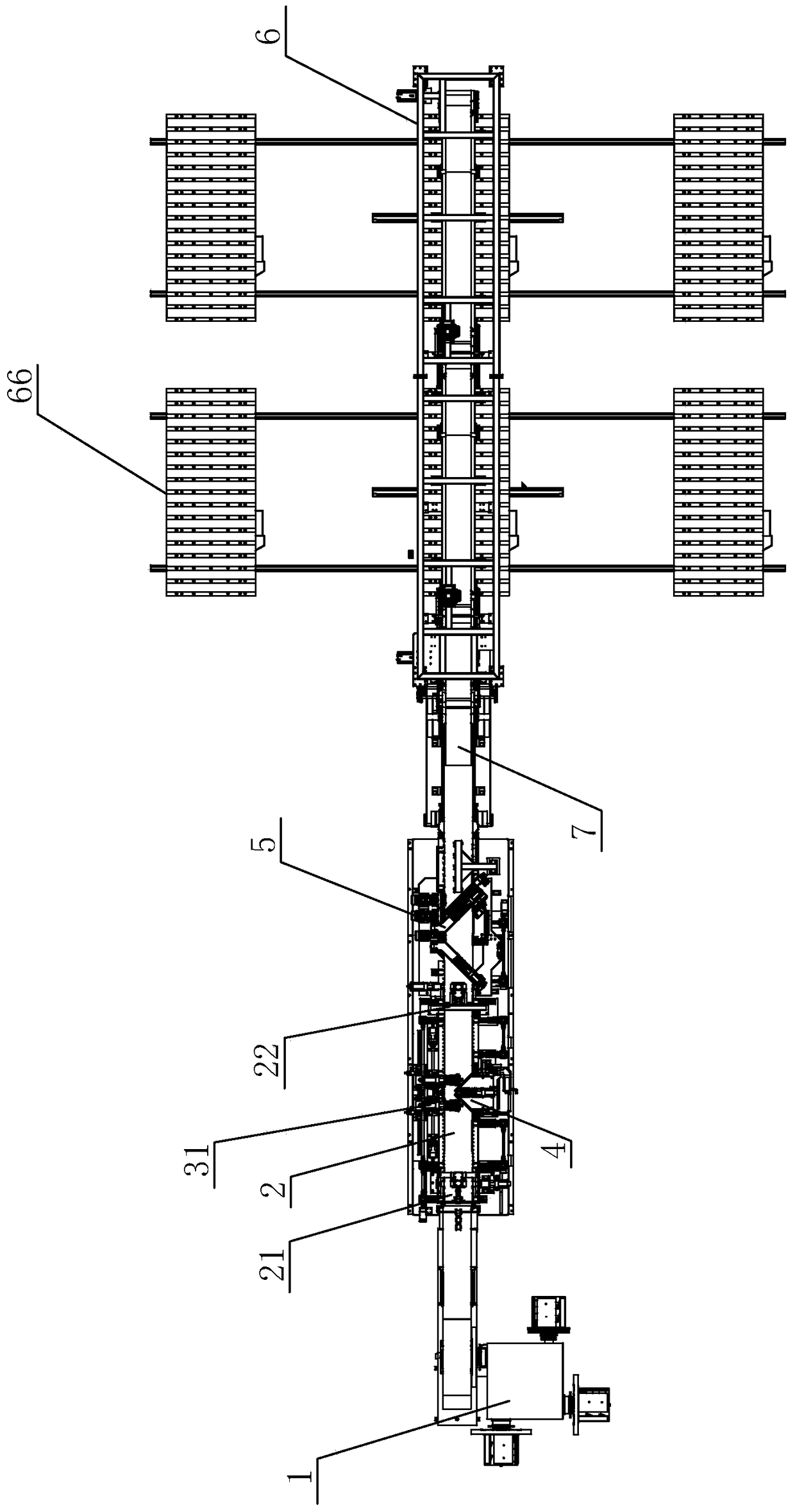

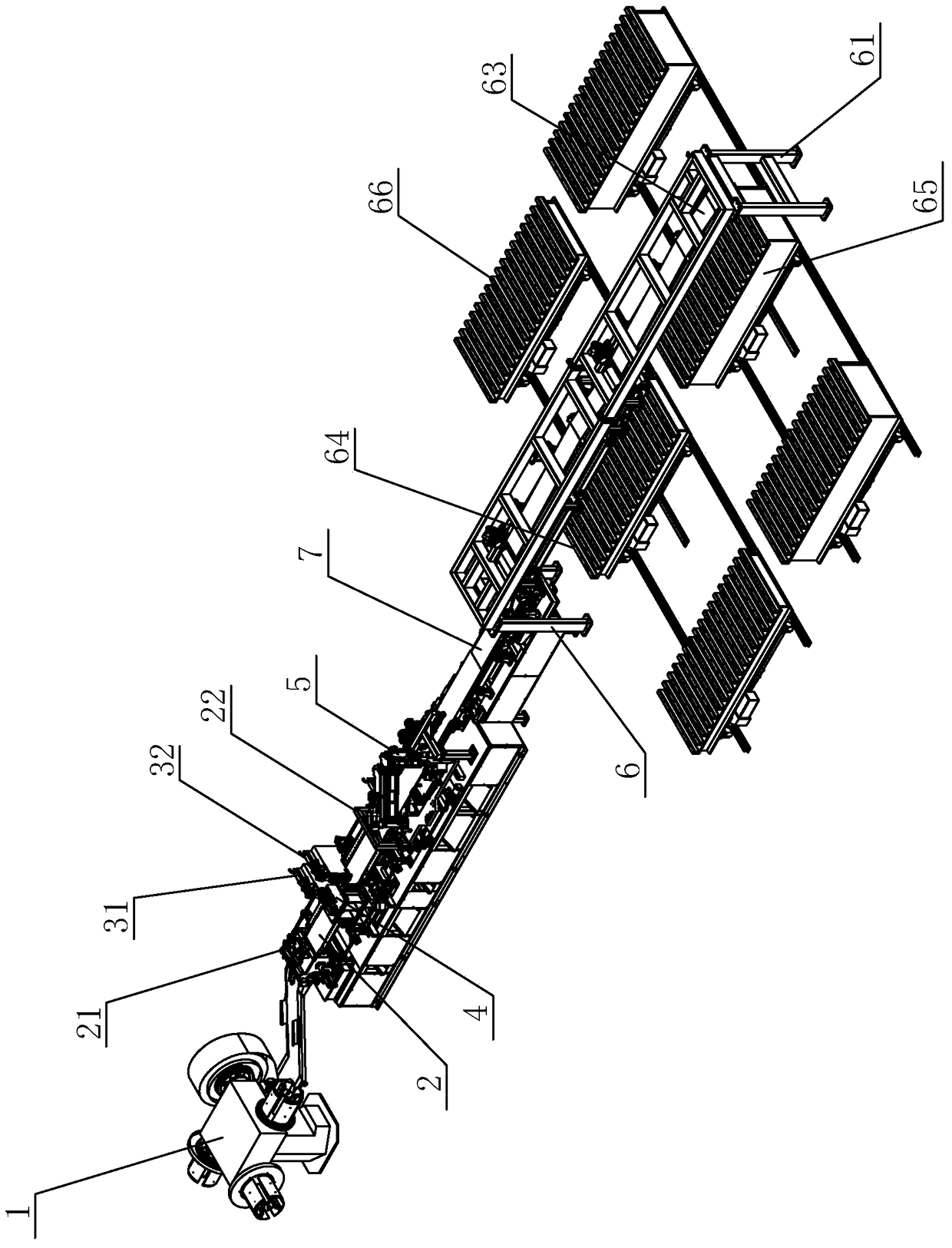

[0049] refer to Figure 1 to Figure 3 , the preferred embodiment provided by the present invention, a new CNC silicon steel sheet cross-cutting line equipment, including a control center, a feeding device 1, and a feeding channel 2, and the feeding channel 2 is sequentially provided with a front feeding device 21, a first Punching device 31 , V-mouth shearing device 4 , second punching device 32 , rear feeding device 22 , pendulum shearing device 5 and discharge platform 7 , and material collecting device 6 is arranged behind discharge platform 7 .

[0050] refer to Figure 4, the discharging device includes a support member 11, and a lifting platform 12 is arranged above the supporting member 11. Preferably, the lifting platform 12 is a square lifting platform, and the four sides of the lifting platform 12 are respectively provided with roll material placement cylinders 13, and the rolled sheets The material is inserted on the roll material placing drum 13. The support memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com