Laser welding method for TA15/Ti2AlNb dissimilar material

A technology of laser welding and dissimilar materials, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as shortage, achieve the effects of excessively smooth welds, reduce costs, and avoid cold cracks in welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The best embodiment of the present invention will be further described in detail below.

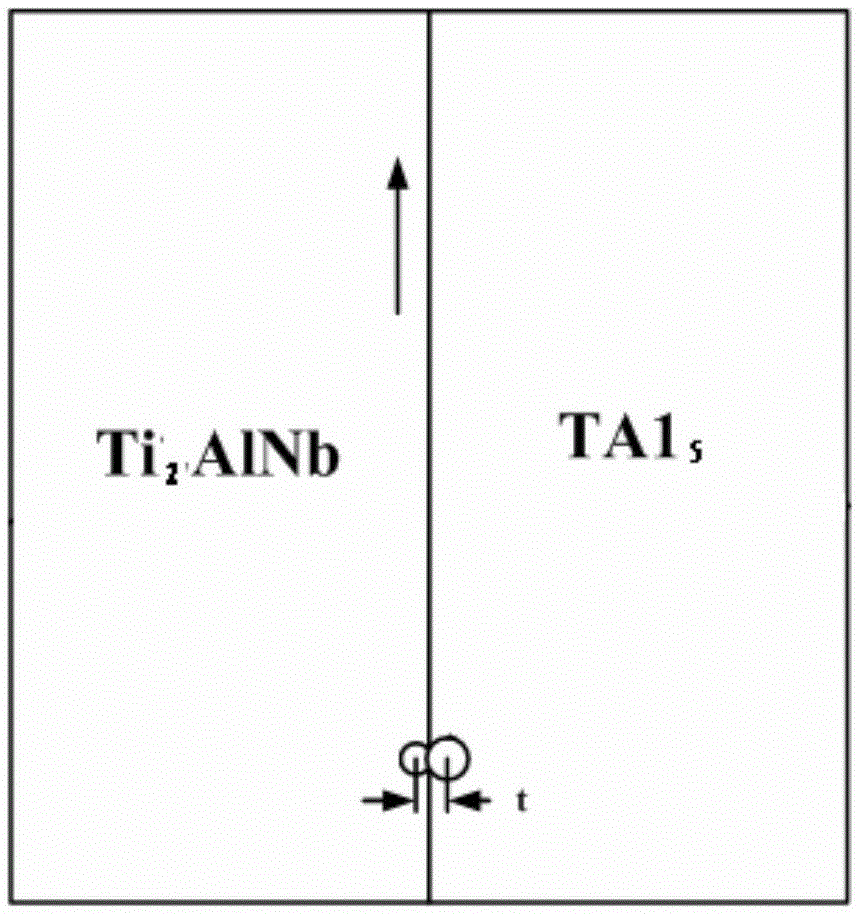

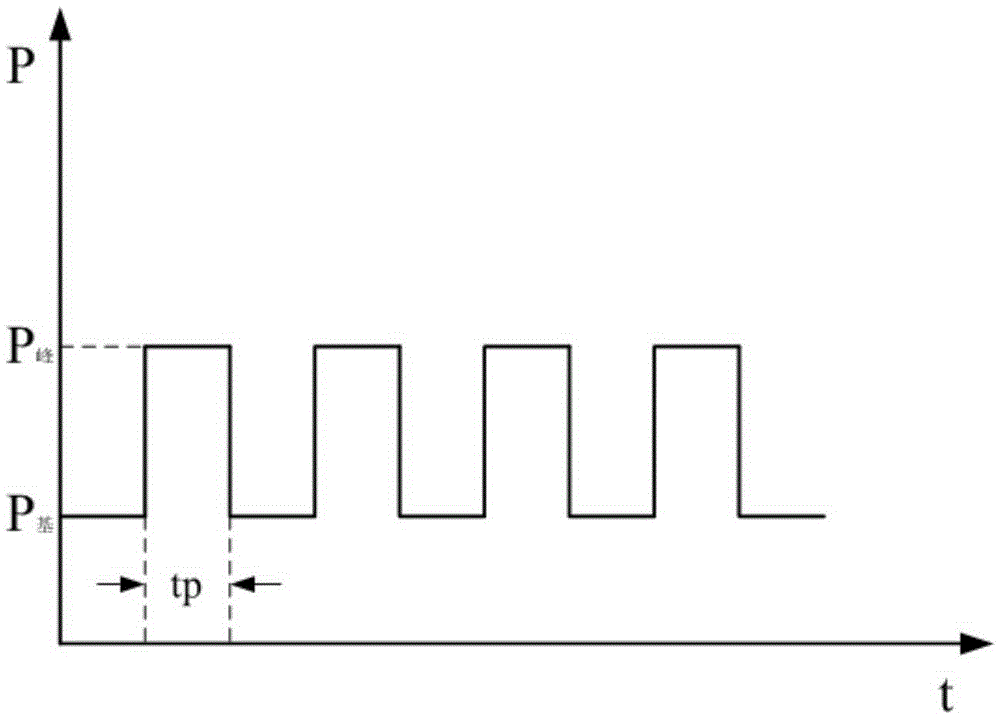

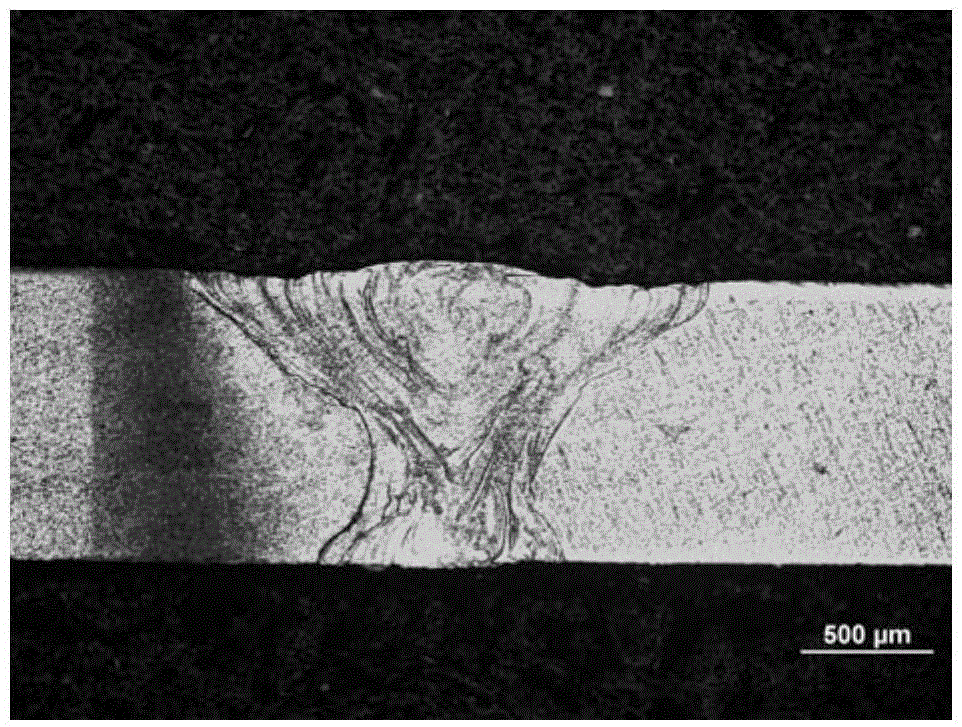

[0028] The TA1 5 / Ti 2 Laser welding method of AlNb dissimilar materials, TA1 before welding 5 Titanium alloy and Ti 2 The AlNb intermetallic compound is pickled, dried and then mechanically polished to clean the surface scale, oil and other impurities. After the test plate is cleaned, the welding is completed within 8 hours. Before welding, ensure that the gap between the two butt joints is less than 0.05mm, and then use Nd:YAG solid-state laser pulse mode for welding. When welding, use side-by-side double spot mode, the spot spacing is 0.36mm, and the spot energy distribution is TA1 5 Titanium alloy side 60%, Ti 2 40% AlNb intermetallic compound on one side, and use 99.99% high-purity argon to protect the front and back of the weld. There is no filler material during welding, and the two materials self-melt to form a weld; when the weld is closed, the arc closing distance can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com