Double-cavity automatic casting and welding mold and its lead supply system

A casting and welding mold and automatic technology, which is applied in the field of battery manufacturing, can solve the problems of unstable alloy composition, poor adhesion on both sides, and easy breakage, etc., and achieves the effects of uniform distribution, good temperature consistency of lead liquid, and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

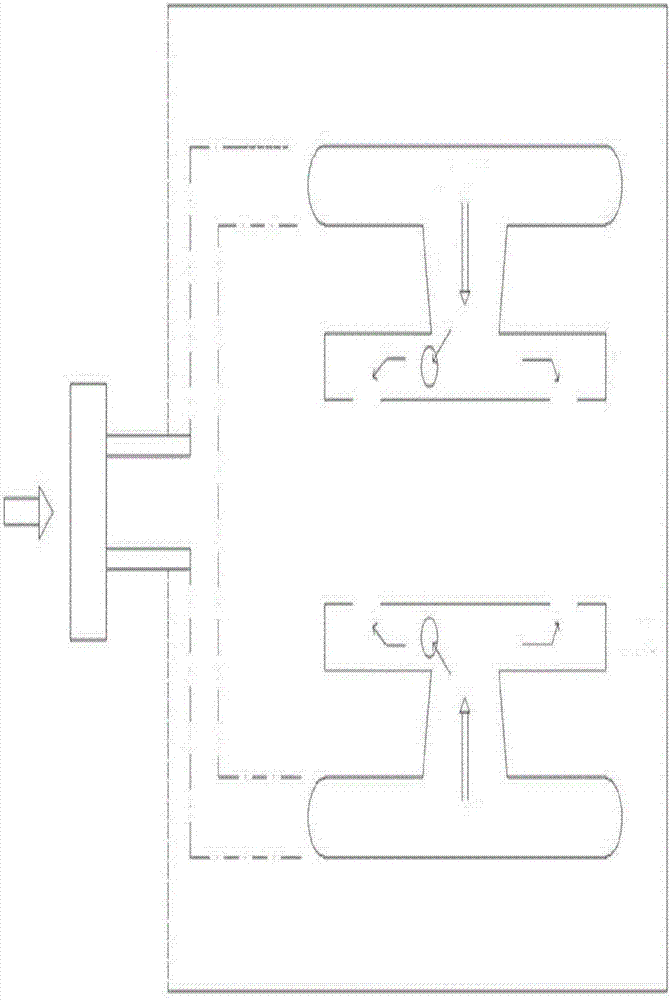

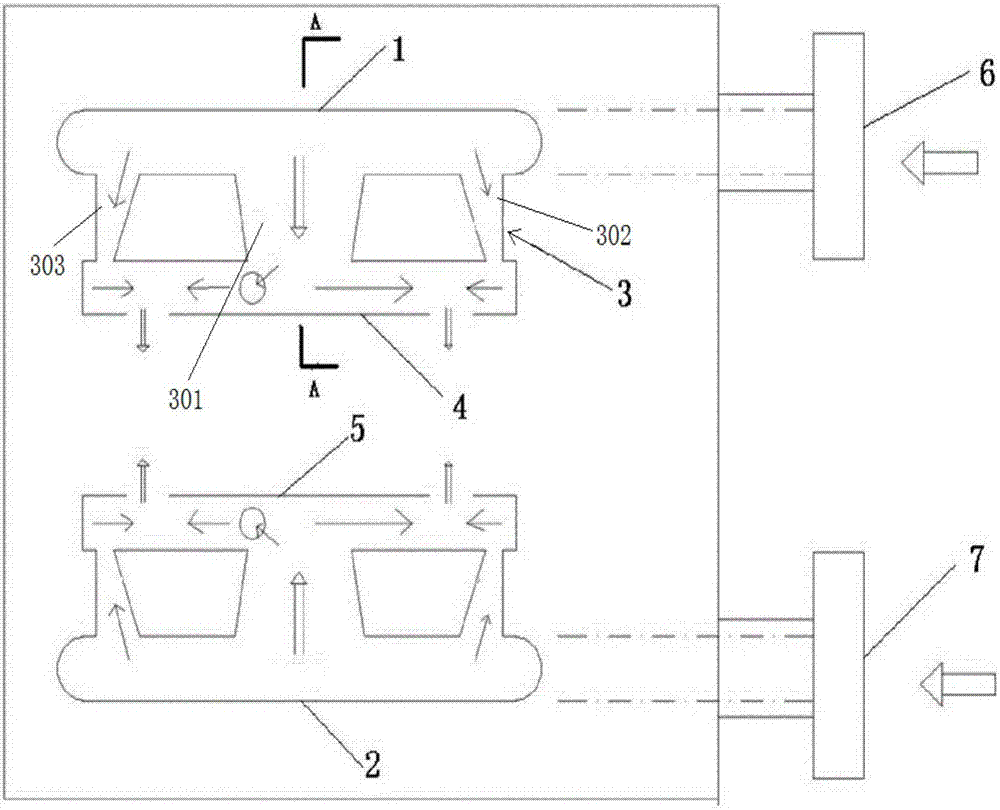

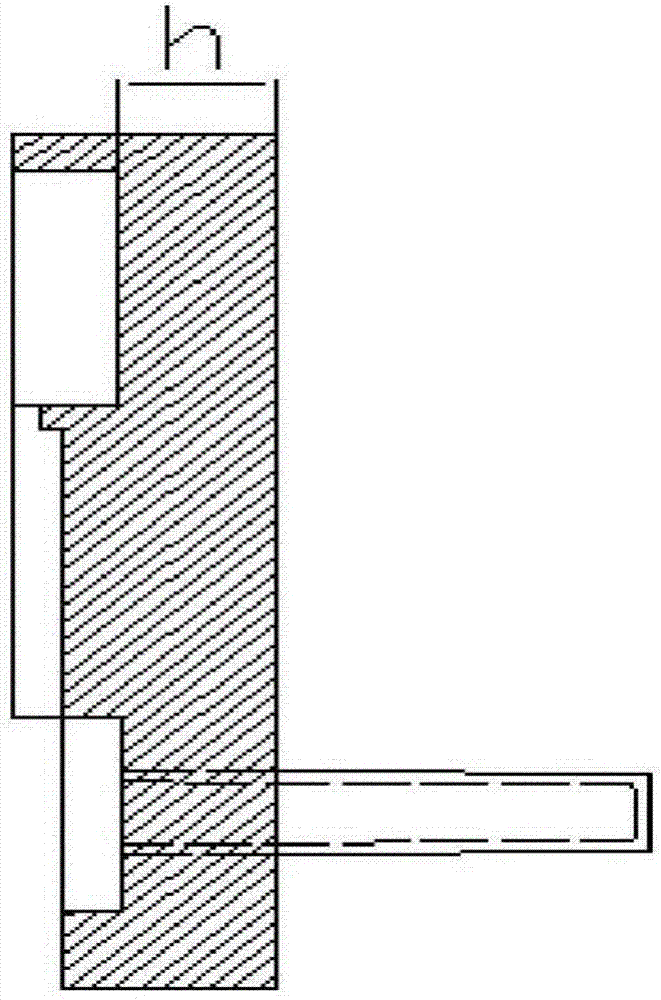

[0015] Such as figure 2 As shown, a double-cavity automatic casting and welding mold and a lead supply system for the mold, the double-cavity automatic casting and welding mold includes a positive bus bar 4, a negative bus bar 5, a positive mold cavity 1, a negative mold cavity 2, and six lead flow ports 3. The positive lead inlet 6 and the negative lead inlet 7, wherein the lower end of the positive cavity 1 is connected to one side of the three lead outlets 3, the other side of the three lead outlets 3 is connected to the positive bus bar 4, and the positive lead inlet 6 is located on the right side of the positive mold cavity 1 and has a certain distance; the positive mold cavity 1, the lead outlet 3 and the positive busbar 4 are internally connected; the positive mold cavity 1, multiple lead outlets 3 and the positive busbar 4 One side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com