Full-automatic sucker rod forging production line

A fully automatic, sucker rod technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, driving devices of forging presses, etc., can solve the problems of manpower and material resources consumption, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

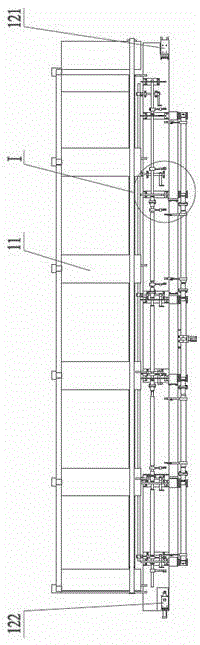

[0084] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 , attached Figure 10 , attached Figure 11 , attached Figure 12 , attached Figure 13 , attached Figure 14 And attached Figure 15 As shown, the fully automatic forging production line for sucker rods includes a mechanical transmission heating system, a pneumatic system, a lubrication system and control components. Loading rack 1, manipulator 2 in front of the furnace, intermediate frequency heating transmission device 3, manipulator 4 behind the furnace, forging device 5, cooling bed 6 and finished material rack 7, the manipulator 2 in front of the furnace will put the bar on the feeding rack Send into the intermediate frequency heating transmission device 3, the manipulator 4 behind the furnace sends the bar material output by the intermediate frequency heating transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com