Preparing method for non-bending ultrathin tungsten wires for Z-pinch torispherical wire array

A tungsten wire and bending technology, which is applied in the field of preparation of non-bending ultra-fine tungsten wire, can solve the problems of reduced strength, no attention to the bending phenomenon of tungsten wire, and low breaking strength of tungsten wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

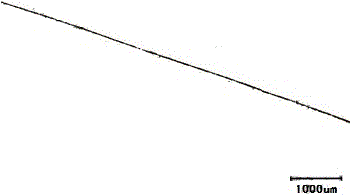

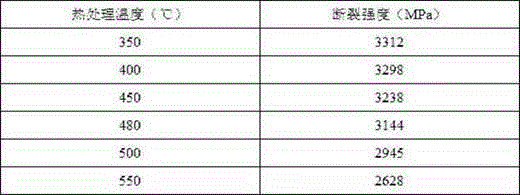

[0022] According to the preparation method of the non-bending ultra-fine tungsten wire used for the Z-pinch quasi-spherical wire array of the present invention, the diameter of the ultra-fine tungsten wire is between 4 μm and 10 μm and there is no bending phenomenon within the range of centimeters. The mixed tungsten wire is used as the raw material for electrolytic corrosion, and the main added elements are Mo (20ppm) and K (85ppm). The preparation and heat treatment of ultra-fine tungsten wire are usually divided into three steps: hot drawing, electrolytic corrosion and annealing heat treatment.

[0023] First, the raw material wire is hot-drawn to control the diameter of the raw material wire at a suitable diameter (a range greater than or equal to 16 μm), so that the first pass of electrolytic corrosion has a large bending span.

[0024] Multi-pass electrolytic corrosion process is carried out, and the ultimate single-pass diameter reduction method is used to maintain the ...

Embodiment 1

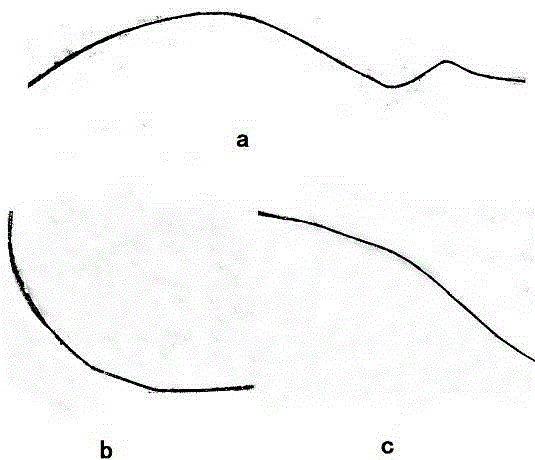

[0028] The electrolytic corrosion raw material wires of different diameters are obtained by the hot drawing method, and a slight electrolytic corrosion is carried out for one pass. The tungsten wire with a lower horizontal length of about 5 cm is counted under a microscope to check whether there is a sharp bend and the average bend span after electrolytic corrosion. Table 1 lists the measurement results. The raw material wires with a diameter of less than 16 μm have sharp bends after slight corrosion; while the raw material wires with a diameter greater than 18 μm have a longer average bending span after electrochemical corrosion, which means a larger curl radius; further increase The diameter of the raw material wire after electrochemical corrosion has little difference in the average bending span, but this will increase the number of electrochemical corrosion passes of the tungsten wire. Therefore, the present invention preferably selects a tungsten wire with a diameter of ab...

Embodiment 2

[0032]The tungsten wire with a diameter of about 21 μm is used for electrolytic corrosion, and the electrolytic voltage of 2.0V is used, and the wire receiving speed is 62.8mm / s. The diameter of the reel is 30mm, but the diameter of the reel is different. The tungsten wires were corroded to Φ6μm with different sizes of wire reels, and the tungsten wires with a horizontal length of about 5cm in the natural state were counted under a microscope, and the average bending span results were listed in Table 2. It can be seen that the average bending span of the tungsten wire is not much different from the average bending span when the diameter of the wire-receiving wheel is smaller than the diameter of the wire-releasing wheel, both are about 2.3mm; when the diameter of the wire-receiving wheel is larger than the diameter of the wire-releasing wheel, The value of the average bending span is related to the diameter of the take-up wheel; when the diameter of the take-up wheel exceeds 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com