Roll coating device and coating technology

A technology for installing equipment and coating rollers, which is applied in the field of roller coating equipment and coating technology, can solve the problems of low production efficiency of stainless steel coating, low production efficiency and energy utilization rate, insufficient surface viscosity, etc., to achieve guaranteed Effect of quality and quality stability, improved accuracy and consistency, good surface leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

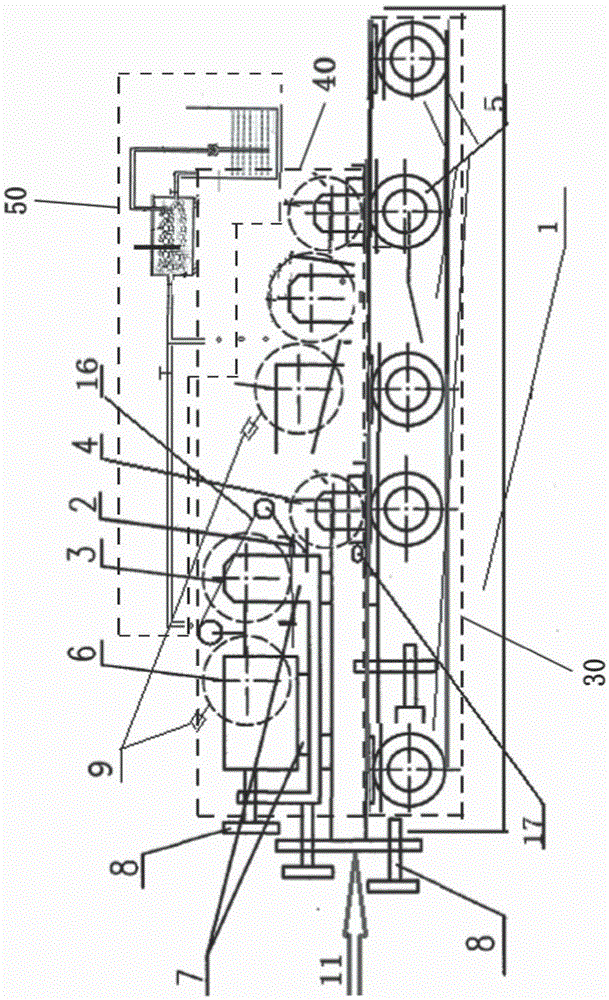

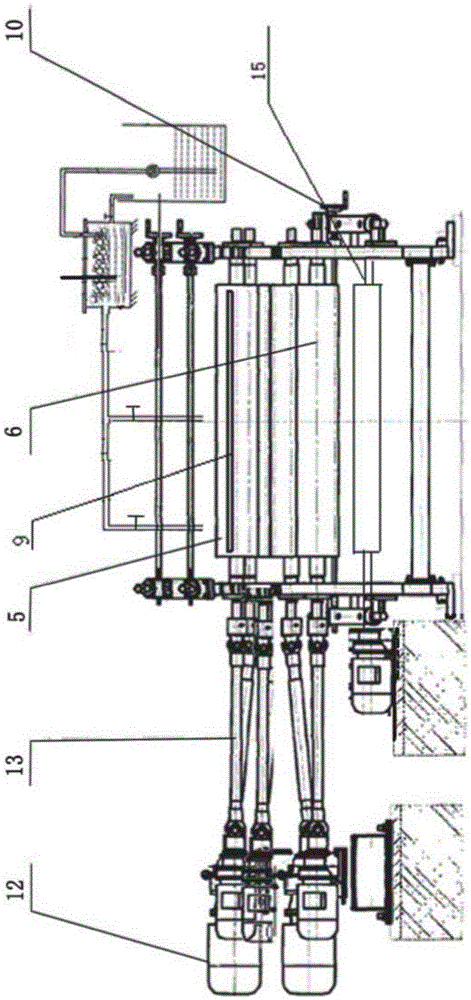

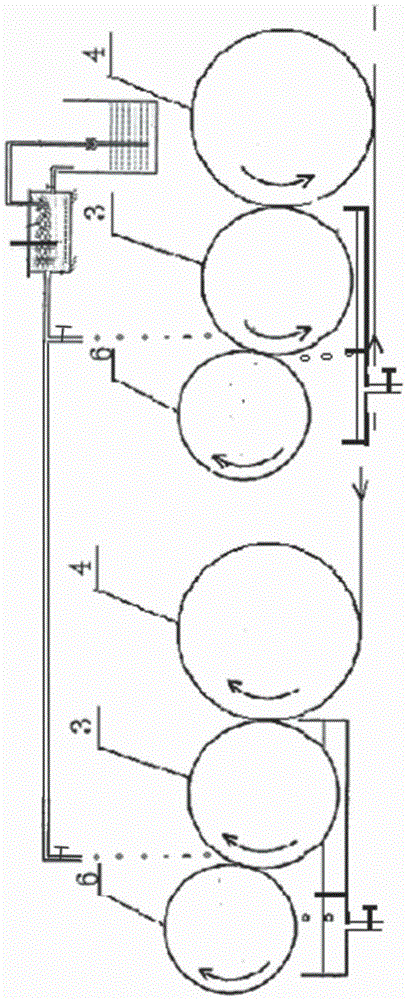

[0039] according to attached Figure 1-4 The roller coating equipment comprises a base (1), a drive system (30) connected to the base (1), a three-roller bottom reclaiming or upper feeding system (40) and a defoaming feeding system (50), The transmission system (30) is connected with the three-roller bottom reclaiming or upper feeding system (40), and the defoaming feeding system (50) extends into the three-roller lower reclaiming or upper feeding system through the feed port (22). above the metering roller (6) in the material system (40); it is characterized in that the three-roller bottom reclaiming or upper feeding system (40) consists of metering roller 1 (6), reclaiming roller 1 (3) and coating Cloth roll 1 (4); metering roll 2 (6), take-up roll 2 (3) and coating roll 2 (4); where metering roll 1 (6) and take-off roll 1 (3) are located on the sliding In the material basin (2) on the block guide rail (7), the slider guide rail (7) is connected on the base (1); the meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com