Negative ion emission needle row assembly

A technology of negative ion emission and needle emission, which is applied in the direction of electrical components, etc., can solve the problems of increasing user burden, increasing use cost, and inability to replace separately, and achieves the effects of eliminating mutual pollution links, high production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

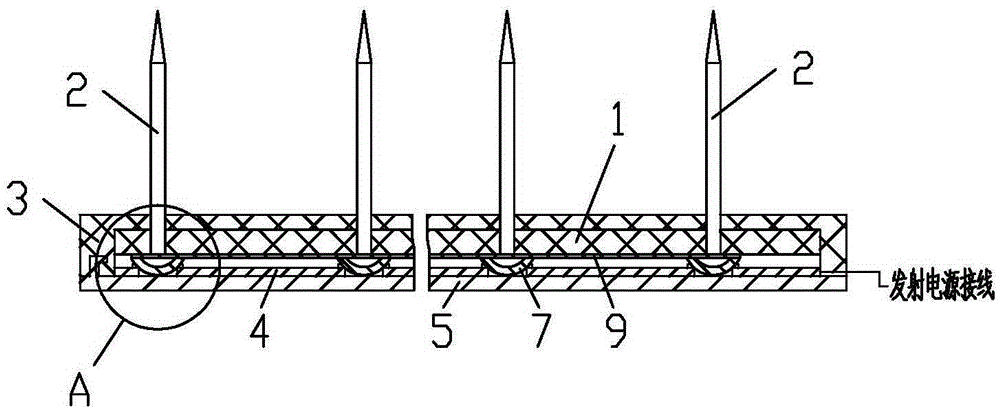

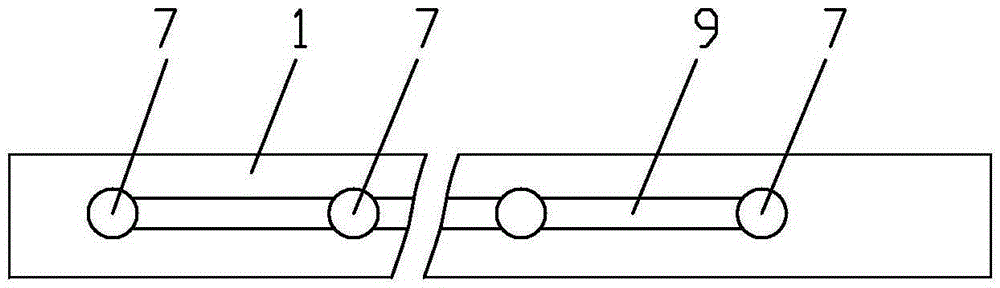

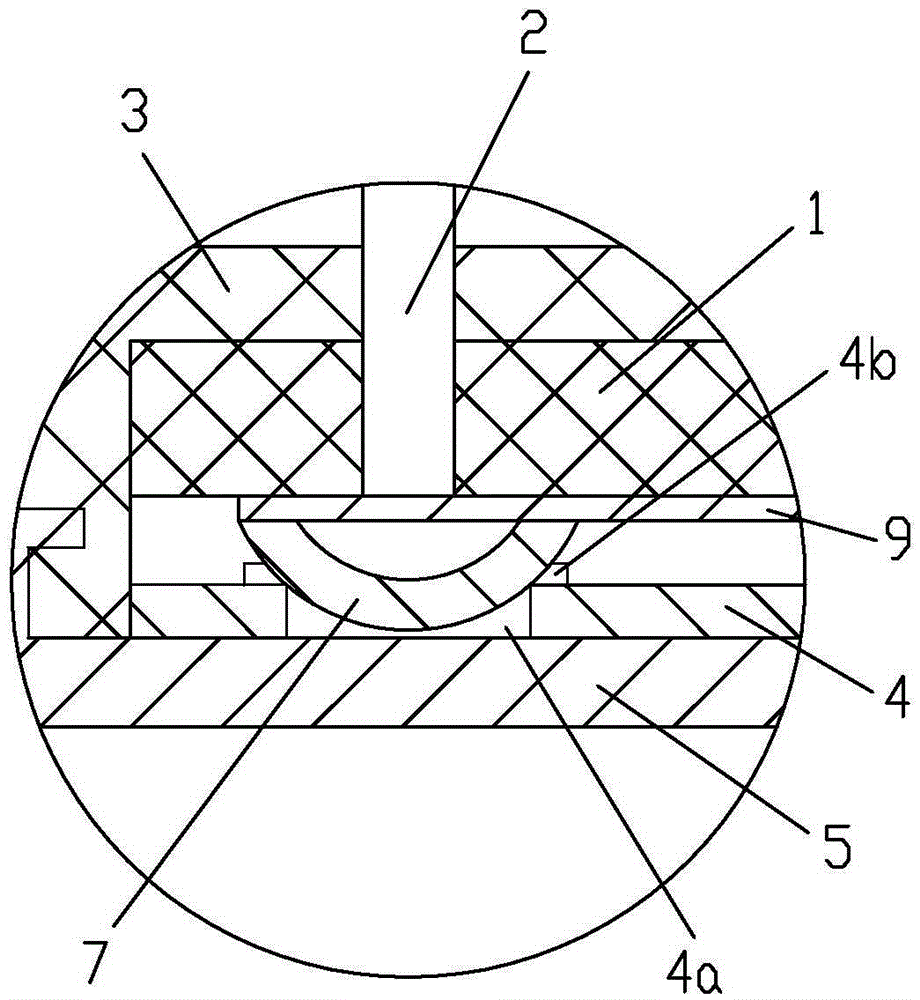

[0017] see figure 1 , figure 2 , image 3 , a negative ion emission needle row assembly, comprising a combination of a plurality of emission needles 2 through a base plate 1 to form an emission pin set, the base plate 1 is in the structure of a printed circuit board, the base plate 1 is arranged in the bottom box 3, and one side of the base plate 1 abuts against the bottom At the bottom of the box 3, the launch pins 2 extend out of the bottom box 3 through the pinholes of the bottom box 3, and the other side of the substrate 1 is provided with a busbar 4, and the busbar 4 is pressed and fixed by the box cover 5 so that it is connected to a plurality of launch pins 2 Both form an electrical connection; the passing tail of the emitting pin 2 is riveted and fixed with the substrate 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com