Pressure-reducing drying device, substrate processing device and pressure-reducing drying method

A technology of decompression drying device and drying method, applied in optics, instruments, optomechanical equipment, etc., can solve problems such as bumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0083]

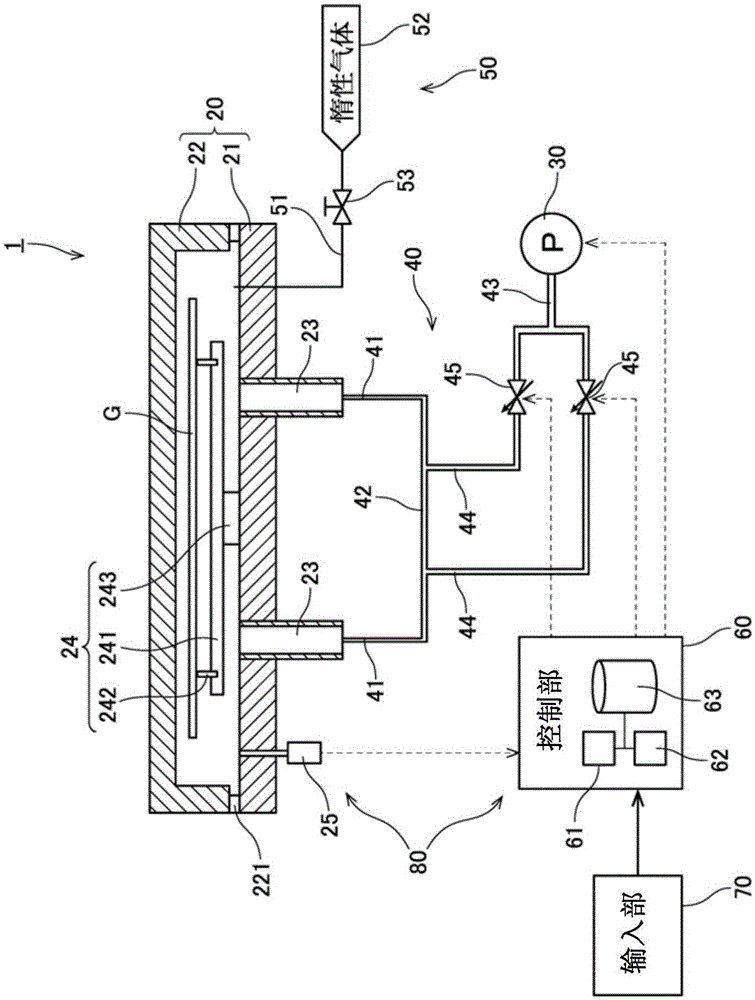

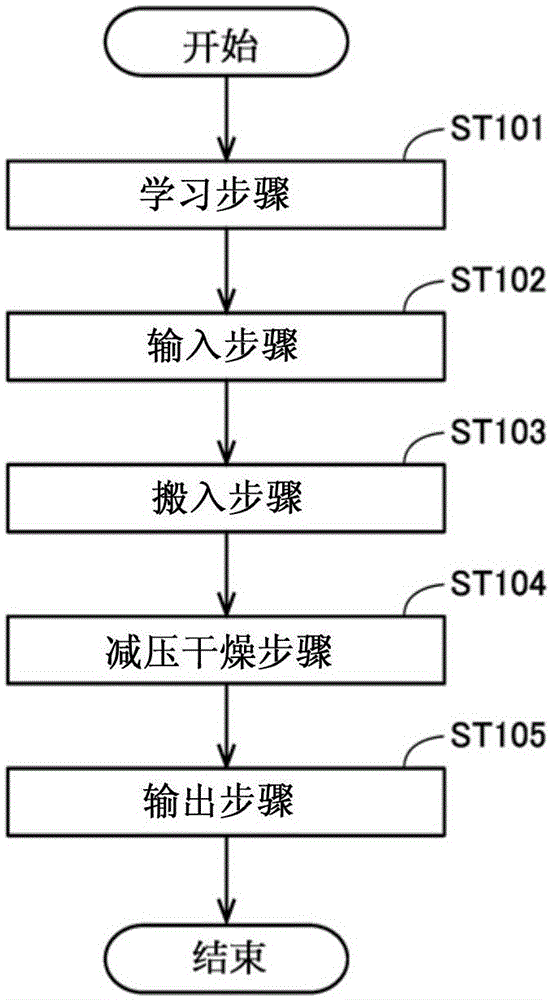

[0084] figure 1 It is a schematic diagram showing the configuration of the substrate processing apparatus 9 including the reduced-pressure drying apparatus 1 according to the first embodiment. The substrate processing apparatus 9 of this embodiment is an apparatus which performs application|coating of resist liquid, exposure, and the image development after exposure to the glass substrate G for liquid crystal display devices. Hereinafter, the glass substrate G for liquid crystal display devices is called a board|substrate G.

[0085] The substrate processing apparatus 9 includes a loading unit 90, a cleaning unit 91, a dehydration bake unit 92, a coating unit 93, a reduced-pressure drying device 1 as a reduced-pressure drying unit, and a pre-bake unit 94. , an exposure unit 95 , a development unit 96 , a rinse unit 97 , a postbake unit 98 , and a carry-out unit 99 serve as a plurality of processing units. The respective processing units of the substrate processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com