An integrated supervision system based on the dyeing and finishing industry

A technology of supervision system and monitoring system, applied in general control system, control/adjustment system, comprehensive factory control, etc., can solve problems such as high monitoring cost and difficult process monitoring, and achieve the effect of reducing input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

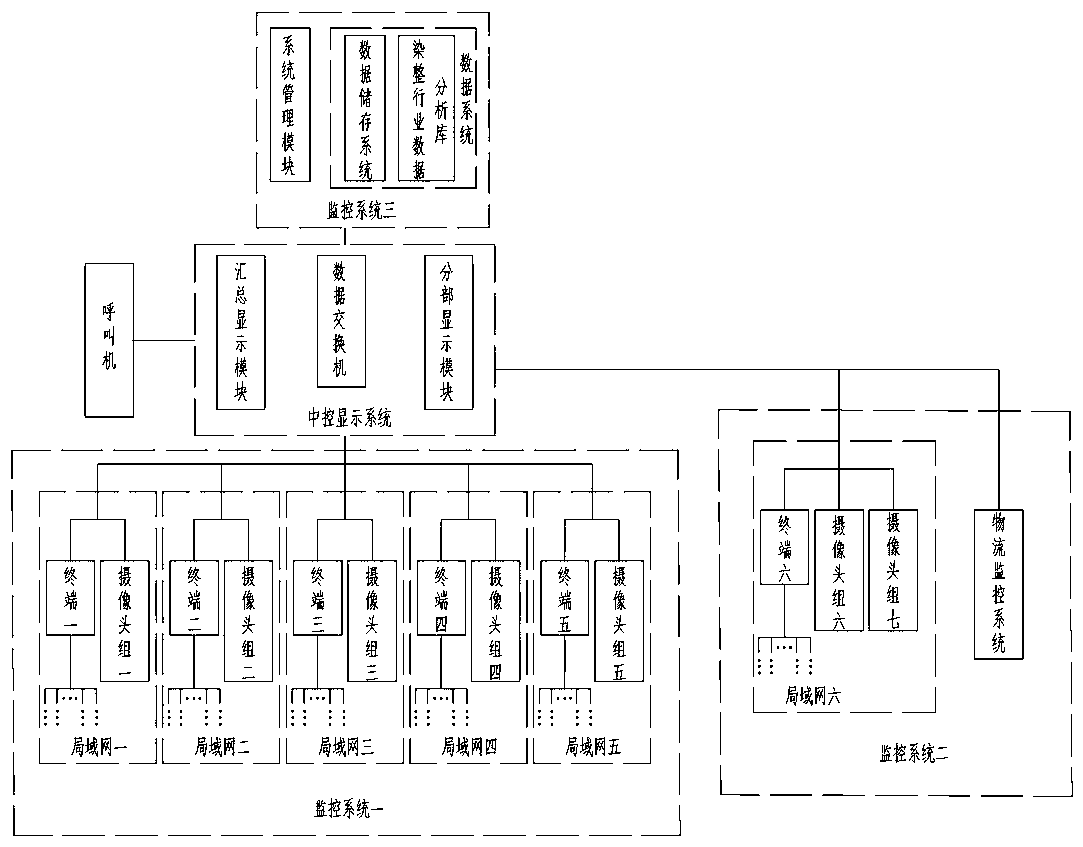

[0029] refer to figure 1 An embodiment of an integrated supervision system based on the dyeing and finishing industry of the present invention will be further described.

[0030] An integrated supervision system based on the dyeing and finishing industry, including a monitoring system set up in the production workshop, a monitoring system set up in the warehouse and used for logistics, a monitoring system based on the cloud for storage and system management, and a factory central control system Display system; monitoring system 1 and monitoring system 2 set up in the manufacturer, the central control display system constitutes a local area network, and the central control display system is connected to the monitoring system in the cloud through the wireless network and the Internet, and the monitoring position is reasonably classified , to facilitate later data classification, storage and analysis, and the monitoring system three for storage and system management is set in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com