Built-in gravity safety valve used for movable storage tank

A mobile safety valve technology, applied in the field of safety valves, can solve problems such as uncontrollable leakage of fluid media, hazards to personnel life safety, difficulties in emergency fire fighting, etc., to deal with failures and accidental damage, improve intrinsic safety, and avoid leakage risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Many cases have shown that the external mode of the medium passage control valve of the hazardous chemical storage tank is the source of hidden dangers of accidental leakage and an important factor that prevents frequent accidents. Obviously, the control valve is closely related to the risk of leakage, and the use of hazardous chemical storage tanks is closely related to petrochemical production, pharmaceutical production, civil gas, and industrial gas, and the consumption is increasing and the movement is frequent. It is of great practical significance to ensure the safety margin of the storage tank and ensure the intrinsic safety of the storage tank. The present invention is exactly the innovative design that this demand is really done.

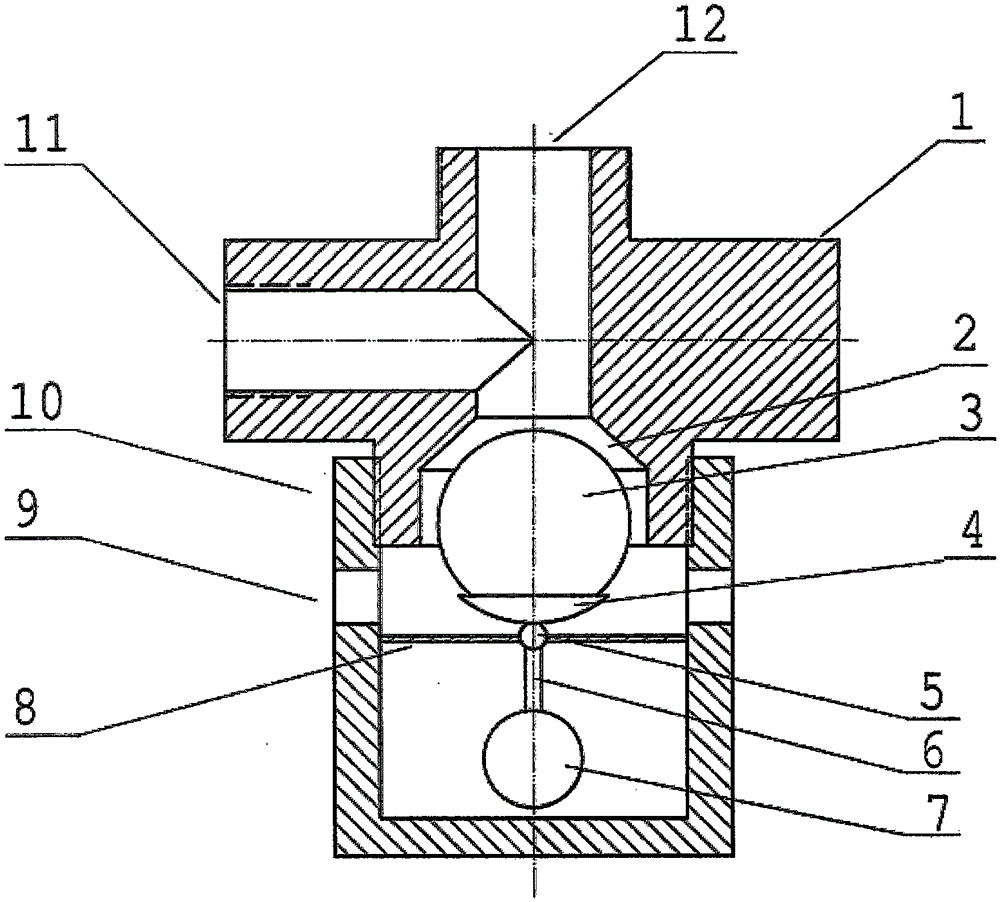

[0016] In order to make the technical solution of the present invention more clearly understood, it will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] Referring to the accompany...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com