A high pressure and large ratio flow regulating valve

A technology of flow regulating valve and large variable ratio, which is applied in the direction of valve lift, valve details, valve device, etc., which can solve the problems of non-replaceable throttling orifice plate, inaccurate flow conditions, complicated control, etc., and achieve light weight and simple control Convenience and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

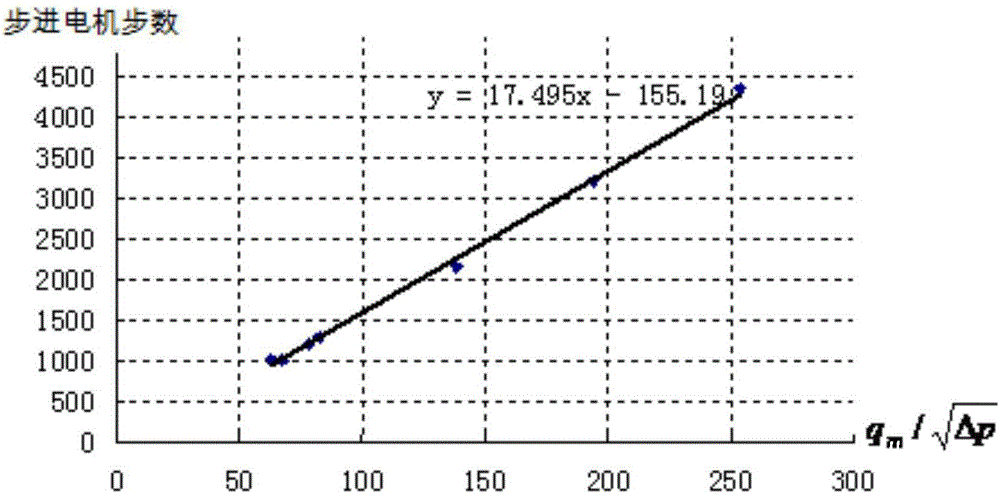

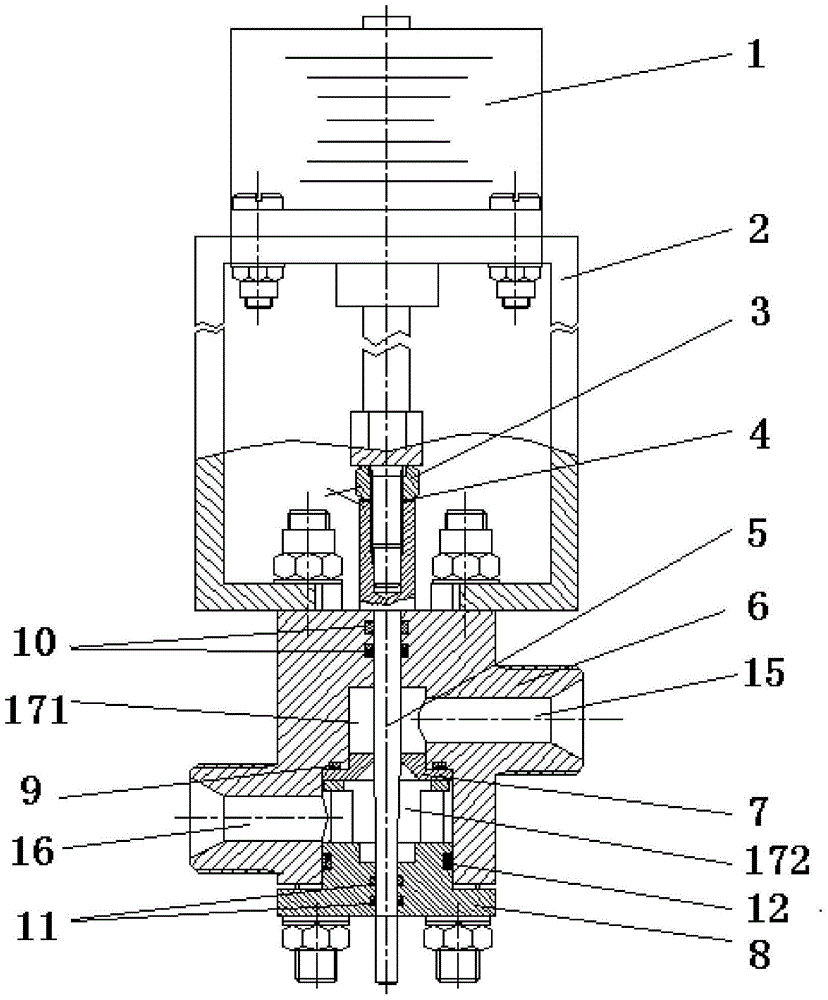

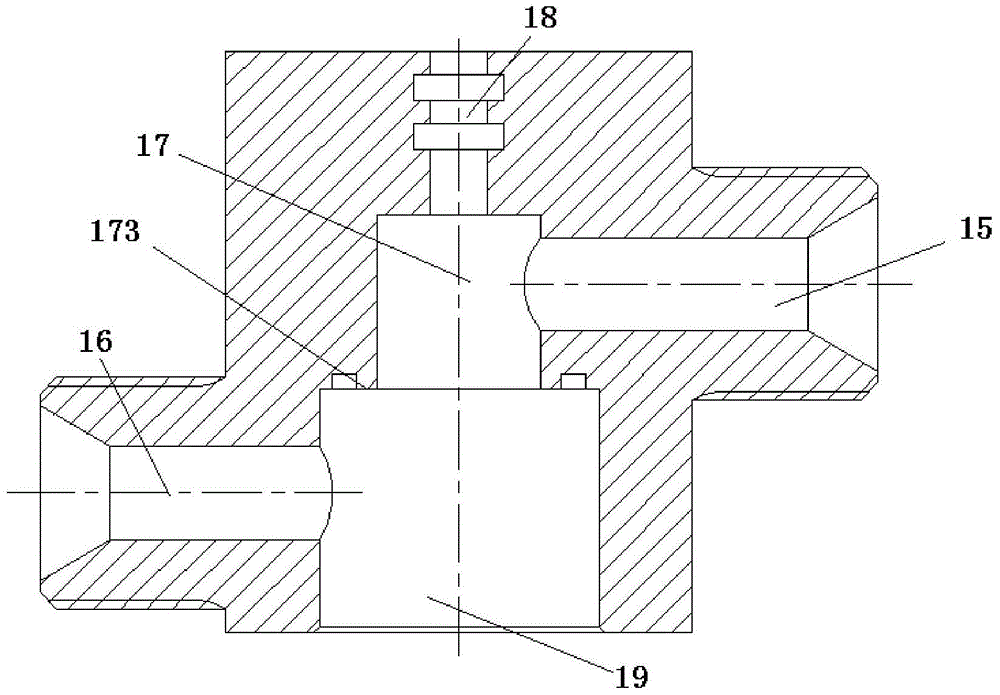

[0038] Such as figure 1As shown, the high pressure and large variable ratio flow regulating valve of the present invention consists of a linear stepper motor 1, a frame 2, a lock nut 3, a saddle gasket 4, an adjusting rod 5, a housing 6, a throttle orifice 7, a pressure plate 8. Composed of rubber O-rings 9 and 10. The inlet passage 15 and the outlet passage 16 are connected by a liquid chamber 17 arranged in the housing, and the throttle orifice 7 is arranged in the liquid chamber 17, and the throttle orifice 7 is provided with a connection between the inlet passage 15 and the outlet passage 16. The throttle hole 71; the adjusting rod 5 is coaxial with the output shaft of the linear stepping motor 1, and the adjusting rod 5 is divided into a fastening part 51 and an adjusting part 52, and the fastening part 51 is fixedly connected with the output shaft of the linear stepping motor 1 , the diameter of the adjustment part 52 is variable, and the housing at one end of the throt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com