Cast-in-situ bored pile with wall protected through microorganism soil solidification and construction method

A technology of bored piles and construction methods, applied in soil protection, sheet pile walls, infrastructure engineering, etc. The effect of increasing the resistance, reducing the deformation of the pile foundation and reducing the engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

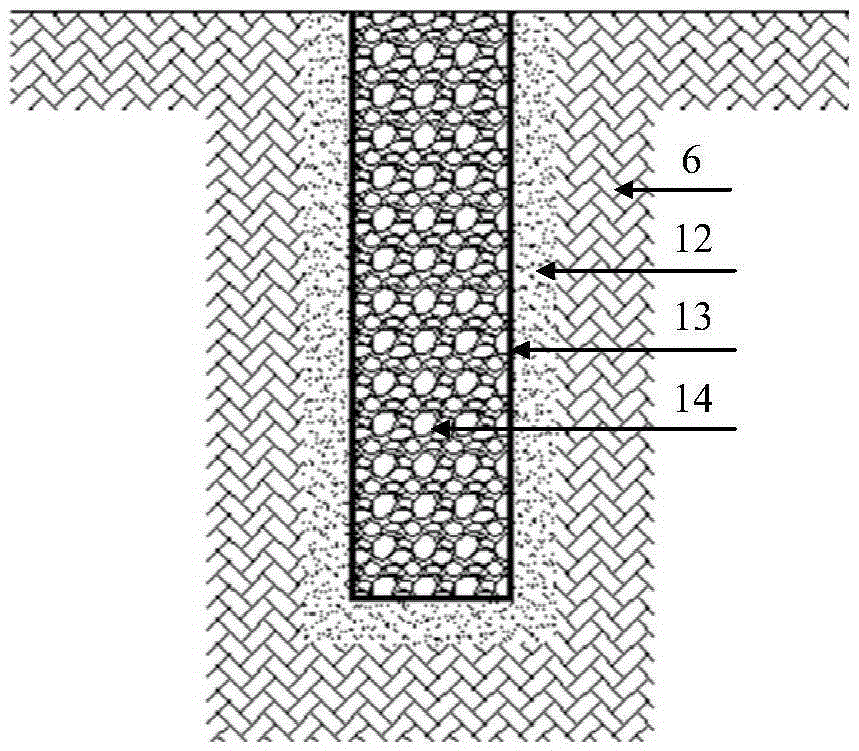

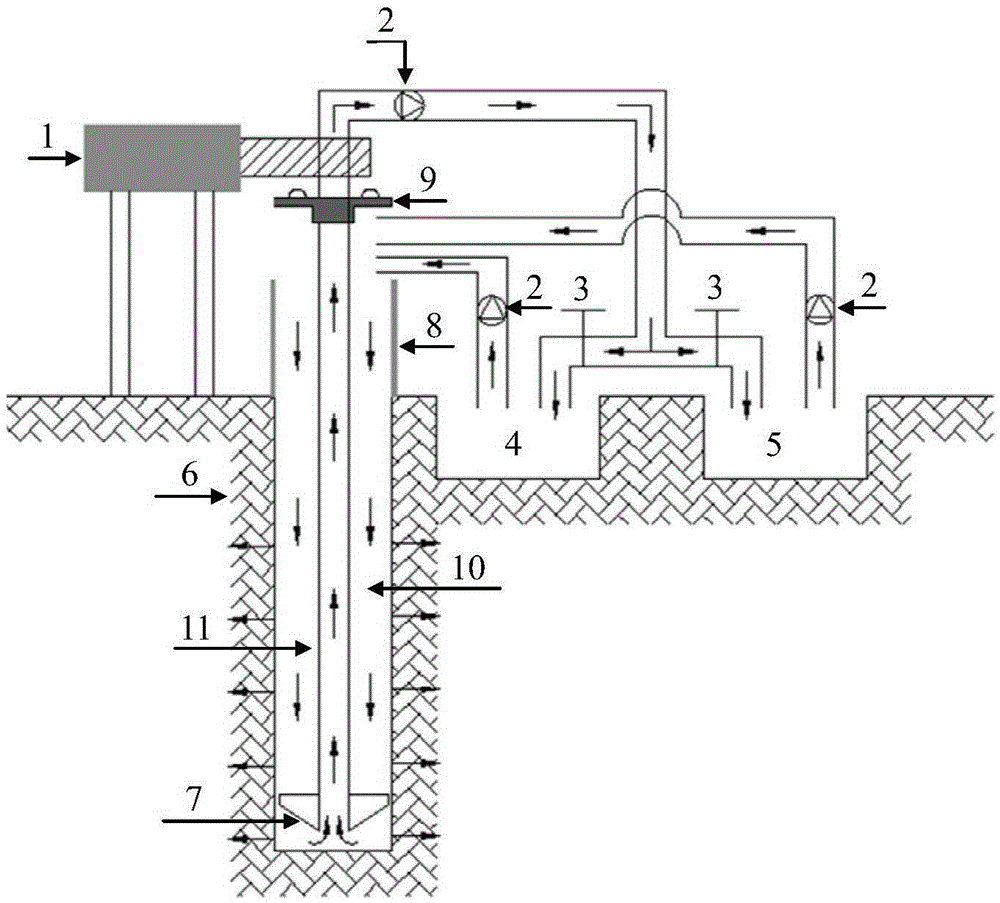

[0028] Embodiment 1 A kind of microbial soil retaining wall bored pile and construction method

[0029] A microbial soil retaining wall bored pile, the cast-in-place pile is composed of a microbial soil solid layer 12, a microbial wall retaining cementation surface 13 and a reinforced concrete cast-in-place pile 14, wherein the microbial soil retaining layer 12 and the microorganism wall retaining The cemented surface 13 is composed of three parts. It is formed by the solidification of calcium carbonate crystals and loosely cemented sand or silt produced by the reaction of microbial bacteria liquid and cementing solution.

[0030] In the described microbial soil-retaining wall-retaining bored cast-in-place pile, the microbial bacterial solution is composed of Bacillus pasteurii and a culture solution, wherein each 1 L of the culture solution contains 15.0 g of tryptone and 5.0 g of soy peptone. g, 5.0 g of sodium chloride and 20.0 g of urea, adjust the pH value of the microbia...

Embodiment 2

[0039] Embodiment 2 A kind of microbial soil retaining wall bored pile and construction method

[0040] A microbial soil retaining wall bored pile, the cast-in-place pile is composed of a microbial soil solid layer 12, a microbial wall retaining cementation surface 13 and a reinforced concrete cast-in-place pile 14, wherein the microbial soil retaining layer 12 and the microorganism wall retaining The cemented surface 13 is composed of three parts. It is formed by the solidification of calcium carbonate crystals and loosely cemented sand or silt produced by the reaction of microbial bacteria liquid and cementing solution.

[0041] In the described microbial soil-retaining wall-retaining bored cast-in-place pile, the microbial bacterial solution is composed of Bacillus pasteurii and a culture solution, wherein each 1 L of the culture solution contains 15.0 g of tryptone and 5.0 g of soy peptone. g, 5.0 g of sodium chloride and 20.0 g of urea, adjust the pH value of the microbia...

Embodiment 3

[0050] Embodiment 3 A kind of microbial soil retaining wall bored pile and construction method

[0051] A microbial soil retaining wall bored pile, the cast-in-place pile is composed of a microbial soil solid layer 12, a microbial wall retaining cementation surface 13 and a reinforced concrete cast-in-place pile 14, wherein the microbial soil retaining layer 12 and the microorganism wall retaining The cemented surface 13 is composed of three parts. It is formed by the solidification of calcium carbonate crystals and loosely cemented sand or silt produced by the reaction of microbial bacteria liquid and cementing solution.

[0052] In the described microbial soil-retaining wall-retaining bored cast-in-place pile, the microbial bacterial solution is composed of Bacillus pasteurii and a culture solution, wherein each 1 L of the culture solution contains 15.0 g of tryptone and 5.0 g of soy peptone. g, 5.0 g of sodium chloride and 20.0 g of urea, adjust the pH value of the microbia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com